DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of custom apparel printing, offering remarkable versatility and quality for both beginners and seasoned pros alike. This innovative printing technique allows for the efficient transfer of vibrant images onto a wide range of fabrics, including cotton and polyester blends, making it a fantastic choice for small businesses and DIY enthusiasts. If you’re exploring how to use DTF transfers, understanding the basics can set you on the right path to creating stunning designs with ease. In this introduction, we will highlight key DTF transfer tips that cater specifically to beginners, ensuring they feel equipped and empowered as they embark on their creative journey. Let’s dive in and discover the best DTF printers and essential tools you need to kickstart your venture into custom apparel printing!

When discussing Direct-to-Film technology, one might also refer to the process as film-based printing or heat transfer printing, both of which emphasize the method of applying detailed designs onto material surfaces. By utilizing advanced techniques in digital printing, artists and entrepreneurs are now able to easily produce high-resolution imagery that adheres seamlessly to various textiles. This alternative approach is not only effective for creating custom clothing items but also serves wider applications across diverse fabric types. As we navigate through the world of fabric decoration, it is vital to grasp essential aspects of film application and transfer methods, which will assist in enhancing your printing capabilities. Join us as we explore these exciting avenues in custom garment creation!

Understanding DTF Transfers and Their Benefits

DTF transfers, or Direct-to-Film transfers, represent a significant innovation in the world of apparel printing. This method allows users to print vivid images directly onto a special film, which can then be seamlessly transferred onto a variety of fabric types. The versatility of DTF transfers means that they work well on cotton, polyester, and mixed fabric blends, making them an excellent choice for custom apparel printing. One of the major benefits of DTF printing is its ability to produce detailed designs with vibrant colors that remain intact even after multiple washes.

Compared to traditional printing methods like screen printing, DTF printing is relatively simpler and more cost-effective, especially for smaller quantities. This ease of use is particularly attractive for those just starting out in custom apparel printing, as it allows for quick adjustments and testing without the higher costs associated with other methods. Additionally, the DTF process does not require complex setups or lengthy production times, making it an ideal solution for both budding entrepreneurs and hobbyists.

Equipment Essentials for DTF Printing Success

When initiating your DTF printing journey, selecting the right equipment is critical for ensuring quality results. First and foremost, a reliable DTF printer is essential. Many beginners find the Epson SureColor P800 series to be an excellent choice due to its affordability and ease of operation. Ensure your printer is compatible with DTF inks to maximize the transfer quality. Alongside the printer, investing in a good heat press that offers adjustable temperature and pressure settings will allow for greater control over the transfer process, thus enhancing the end product.

Apart from printers and heat presses, you will also need quality DTF films and inks. The choice of film significantly impacts the adhesion and vibrancy of your designs, making it crucial to choose high-grade materials specifically designed for DTF printing. High-quality DTF inks not only provide better color output but also ensure that your prints withstand the test of time, maintaining their brightness after repeated washes. As a beginner, careful selection of these materials can elevate the quality of your results and increase your satisfaction with your custom printing efforts.

Mastering the DTF Transfer Process Step-by-Step

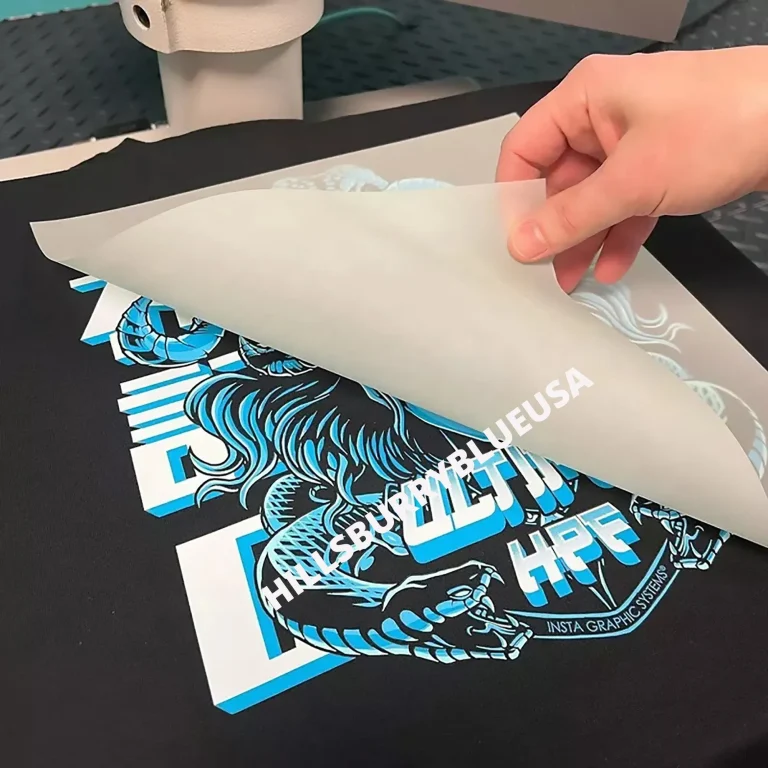

Once you are equipped with the right tools, it’s time to familiarize yourself with the DTF transfer process. Start by preparing your design using graphic design software, ensuring it is mirrored before being printed onto the DTF film. This step is critical, as it guarantees your finished design appears correctly when transferred to fabric. After printing, apply an even layer of adhesive powder to the inked side. This step is vital for proper adhesion to the fabric during the heat transfer.

Next, the heat-setting phase is crucial. Once you’ve applied the adhesive powder, use your heat press to set the transfer. Adjust the press to the recommended temperature and time settings for the materials you’re working with. Once the press completes its cycle, carefully peel the film away from the fabric. Following the transfer, allow the apparel to cure for at least 24 hours before washing, as this will help secure the transfer’s durability and longevity. Understanding each step meticulously will lead to more successful outcomes and high-quality products.

DTF Transfer Tips for Beginners

To become proficient in DTF transfers, it’s important to utilize effective tips that can help refine your skills. Begin with simple designs as you gain confidence in your abilities. Test prints on regular paper before committing to DTF film can save time and material costs. Utilize this procedure to check the colors and design alignment so that adjustments can be made before the final print. Additionally, be meticulous with your settings on the printer—using high-quality print settings will yield clearer images with better color as opposed to standard settings.

Moreover, joining online communities or forums dedicated to DTF printing can provide valuable insight and troubleshooting tips. Many experienced users share their insights on platforms like Facebook Groups or Reddit, where anyone can ask questions or seek advice. Additionally, video tutorials on platforms like YouTube can offer visual guidance, allowing you to see the process in action and learn from real-world experiences. Gathering knowledge from various resources will significantly increase your proficiency and boost your confidence as you begin creating custom apparel.

Exploring the Best DTF Printers on the Market

In the realm of DTF printing, choosing the right printer can greatly impact your success. Many beginners find that investing in a high-quality DTF printer pays dividends in the long run. Printers like the Epson SureColor series are often highlighted for their balance of affordability, user-friendliness, and printing capabilities. The right printer should not only be compatible with DTF inks but also have the ability to create detailed designs that are characteristic of high-quality custom apparel.

Beyond Epson, several other brands have started gaining traction in the DTF printer market, offering advanced features and enhanced printing technology. It’s advisable to conduct thorough research and read user reviews, as these can provide insights into the operational efficiency and reliability of different models. Comparing various printers in terms of print speed, quality, and maintenance will help you make an informed choice that suits your specific needs and budget.

The Future of DTF Printing in Custom Apparel

As the demand for custom apparel continues to rise, DTF printing stands at the forefront, revolutionizing the fabric printing industry. With its capacity for vibrant designs and ease of use, DTF printing is expected to grow in popularity among various user demographics. Many small businesses and entrepreneurs are transitioning to this method due to its cost-effectiveness for small runs and ability to produce high-quality prints that meet customer demands.

Looking ahead, advancements in printing technology and materials are likely to further enhance the possibilities with DTF transfers. As more businesses adopt this printing method, the growth of instructional resources, tips, and community support will play a significant role in helping beginners and experienced users alike improve their craft. Involvement in this flourishing community is essential for keeping up with the latest techniques and innovations, ensuring that you are well-prepped to adapt and thrive in the evolving landscape of custom apparel printing.

Frequently Asked Questions

What are the essential tips for using DTF transfers effectively?

To use DTF transfers effectively, start by selecting the right equipment, including a quality DTF printer and a reliable heat press. Ensure you use DTF-specific films and inks for vibrant prints. Prepare your designs in high resolution and remember to mirror them before printing. Properly apply adhesive powder to the printed film and follow the correct heat-setting process to ensure a successful transfer onto fabrics.

How can beginners learn DTF printing techniques?

Beginners can learn DTF printing techniques by engaging with online communities, joining forums, and watching YouTube tutorials focused on DTF printing. Additionally, reading blogs and articles about DTF transfers provides insights into best practices and troubleshooting tips, which can enhance their skills and confidence in this craft.

What are the best DTF printers for beginners?

For beginners, the Epson SureColor P800 series is highly recommended as it offers excellent quality prints and compatibility with DTF inks. Other models like the Epson L805 or similar devices are also suitable for entry-level DTF printing, as they provide reliable performance and ease of use.

Can you explain the DTF transfer process step-by-step?

The DTF transfer process involves several key steps: first, print your design onto DTF film using a suitable printer. Then, apply adhesive powder to the printed side of the film. Heat-set the film using a heat press to activate the adhesive, and finally, transfer it onto your fabric by applying heat and pressure. Allow the transfer to cool before peeling away the film.

What are common mistakes to avoid when creating custom apparel with DTF transfers?

Common mistakes to avoid include not mirroring designs before printing, using incompatible inks or films, and failing to test print designs before transferring onto fabric. Additionally, ensure proper temperature and pressure settings during the heat press process to avoid poor transfer quality. Take your time to follow each step meticulously to achieve the best results.

How do I care for items printed with DTF transfers?

To care for items printed with DTF transfers, avoid washing them for at least 24 hours after the initial transfer to allow the adhesive to set properly. When washing, use cold water and air dry to maintain the vibrancy and durability of the prints. Refrain from bleach and harsh detergents to prolong the life of your custom designs.

| Key Points | |

|---|---|

| Introduction to DTF Transfers | DTF transfers are a popular method for customizing apparel and textiles, offering high-quality imagery on various fabrics. |

| Overview of DTF Transfers | DTF printing involves transferring an image from a special film to fabric with heat, known for its vibrant colors and durability. |

| Essential Tools and Equipment | You’ll need a DTF printer, heat press, DTF films, DTF inks, and design software. |

| Getting Started with DTF | Follow steps for printing, applying adhesive, transferring to fabric, and post-transfer care. |

| Learning Resources | Engage with online communities, watch tutorial videos, and read blogs to improve your skills. |

Summary

DTF transfers are an innovative way to create custom designs on apparel, making them a popular choice among businesses and hobbyists alike. This method allows users to achieve vibrant, durable prints while maintaining efficiency and ease of use. As you embark on your journey into DTF transfers, remember that having the right equipment and knowledge will set a solid foundation for your projects. Through practice and engagement with the DTF community, you can develop your skills and produce stunning custom apparel that stands out in the market.