In the realm of custom printing, **DTF transfers** (Direct to Film transfers) have garnered significant attention due to their innovative approach to design application. This printing technique involves transferring vibrant designs onto a specialized film before applying them to various materials, especially fabrics, resulting in high-quality and durable prints. DTF printing not only allows for intricate details but also enhances color fidelity, making it a standout choice in the growing market of custom apparel. Furthermore, the ease of use and versatility of the DTF transfer process make it accessible for everyone, from hobbyists to small business owners. As we explore the benefits of DTF transfers and the essential supplies needed to get started, this guide will equip you with everything you need to embark on your custom printing journey.

DTF transfers, also known as Direct to Film transfers, represent a cutting-edge method in the world of fabric printing, offering a gateway to innovative design possibilities. This technique allows for the application of detailed and colorful artwork onto textiles using a film medium, revolutionizing the way custom apparel is created. With a growing interest in personalized clothing solutions, many enthusiasts and entrepreneurs are turning to this method, intrigued by its practicality and the benefits of DTF printing. This versatile process not only accommodates various fabric types but also streamlines production, making it an attractive option for diverse applications in the custom clothing sector. As we dive deeper into the dynamics of DTF printing and its advantages, readers will gain insights into how to effectively navigate this exciting printing avenue.

Understanding the Basics of DTF Transfers

DTF transfers, or Direct to Film transfers, revolutionize how designs are printed onto fabrics. The process starts with creating a digital design, which is then printed on a specialized film using DTF-optimized inks. This method allows for detailed and vibrant prints, offering a solution for custom apparel that stands out in a crowded market. Unlike traditional methods which may be restricted by fabric type or design complexity, DTF transfers provide a broad canvas that includes not just cotton but also polyester and blends, enhancing versatility for users.

The film used in DTF transfers is engineered to facilitate a seamless transfer of designs onto various materials. Once printed, an adhesive powder is applied over the ink, ensuring that the design adheres correctly when heat is applied through a heat press. This innovative approach eliminates many limitations found in traditional printing techniques, making DTF a go-to choice for hobbyists and professionals alike.

The Process Behind DTF Transfer Printing

The DTF transfer process can be divided into several crucial stages that ensure high-quality results. First, users need to create their designs digitally, which are printed onto the DTF film using specialized DTF printers equipped to handle the intricacies of the process. Once the design is printed, a layer of adhesive powder is sprinkled onto the wet ink, and this is a vital step for ensuring the design will bond perfectly to the selected fabric.

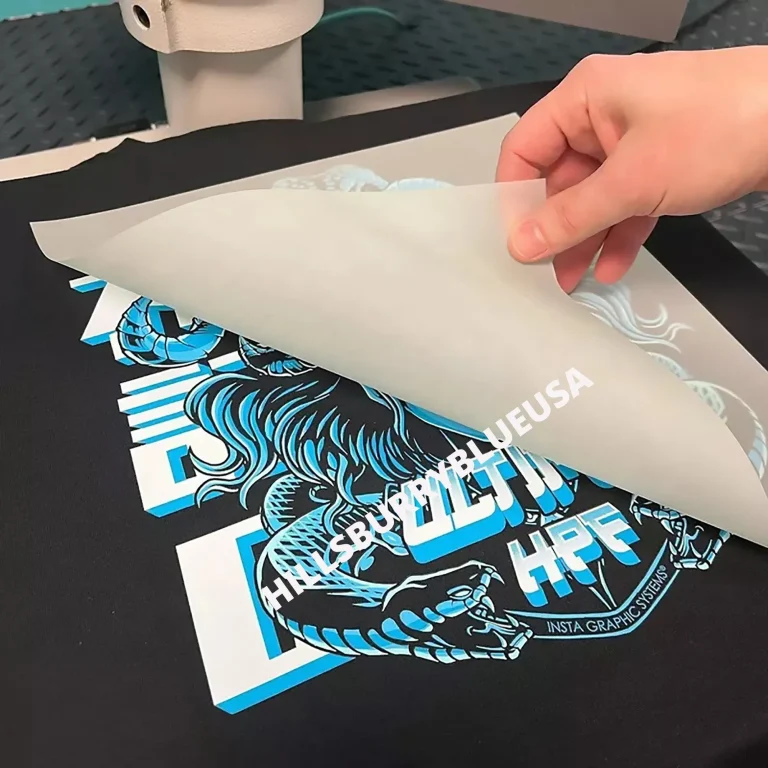

After applying the adhesive powder, the final step is heat pressing the film onto the fabric. This is where the magic happens; the combination of heat and pressure transfers the design from the film to the garment, creating a durable and vibrant print. Understanding this step-by-step process is essential for anyone looking to master DTF transfers, as each phase contributes to the quality of the end product.

Advantages of Utilizing DTF Transfers

DTF transfers come packed with benefits that make them a favorable choice in the world of custom apparel. One of the most remarkable advantages is the exceptional print quality; colors are not only vibrant but also rich in detail, often surpassing what traditional printing methods can achieve. This high quality makes DTF an attractive option for businesses aiming to create eye-catching designs that enhance customer appeal.

Moreover, DTF transfers are incredibly versatile. They can be used on various materials beyond just cotton, including blends and synthetic fabrics, broadening the scope for creative applications. This adaptability allows users to create an array of products, from clothing items like t-shirts to promotional materials like tote bags, making DTF suitable for both personal projects and commercial endeavors.

Critical Equipment for DTF Printing Success

Success in DTF printing requires specific equipment tailored to the process. At the forefront is the specialized DTF printer, which is essential for achieving high-quality prints. Popular options, especially from brands like Epson, are favored, but users can also modify certain existing printers to accommodate DTF printing, making it accessible to a wider range of users.

In addition to the printer, selecting high-quality DTF films and inks is crucial for successful transfers. The right choice of films ensures that the prints adhere correctly and maintain their vibrancy over time. Furthermore, adhesive powder acts as a binding agent, ensuring that designs solidify on the fabric during the heat transfer process. Investing in quality equipment and supplies can significantly enhance the durability and appearance of the final product.

Addressing Challenges in DTF Transfers

While DTF transfers bring numerous advantages, they are not without challenges. One of the primary obstacles for newcomers to DTF printing is the initial setup costs, which can be significant depending on the quality of equipment and supplies chosen. For those just starting, this can present a barrier to entry, requiring careful budgeting and planning.

Additionally, mastering the DTF printing process involves navigating a steeper learning curve compared to other printing methods. Users must develop an understanding of how to control significant variables, such as heat and pressure, to produce consistent and high-quality results. Familiarizing oneself with these intricacies is vital for long-term success in custom printing through DTF.

Exploring the Future of DTF Transfers

The future of DTF transfers looks incredibly promising, with market growth driven by the surging demand for custom apparel and unique printing solutions. As businesses seek cost-effective and high-quality printing options, DTF has positioned itself as a viable alternative to traditional methods like screen printing. This trend indicates a promising landscape for entrepreneurs and hobbyists alike as they explore new avenues in custom printing.

Moreover, the increasing availability of online resources such as tutorials and courses allows newcomers to gain confidence in the DTF process. As techniques for perfecting DTF transfers become more accessible, the barrier to entry continues to lower, encouraging a new generation of creatives to embrace custom printing. This shift not only democratizes access to high-quality printing but also fosters innovation within the industry.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film which is then heat pressed onto fabrics. This method allows for vibrant, high-quality prints, making it a popular choice for custom apparel.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers several benefits, including high-quality vibrancy, versatility across different fabric types, and ease of use compared to traditional methods like screen printing, making it ideal for creating custom apparel.

What equipment do I need to get started with DTF transfers?

To start using DTF transfers, you’ll need a specialized DTF printer, DTF-specific inks and films, and adhesive powder. These supplies are essential for successfully executing the DTF transfer process.

Can DTF transfers be used on different materials?

Yes, one of the main advantages of DTF transfers is their versatility; they can be applied to various materials including cotton, polyester, and blends, making them suitable for a wide range of custom apparel items.

What is the DTF transfer process like?

The DTF transfer process includes designing a graphic, printing it onto DTF film, applying adhesive powder, and then heat pressing the film onto the fabric. Each step is crucial for achieving a durable and vibrant final product.

What challenges should I consider when using DTF printing?

Challenges of DTF printing include initial setup costs, a learning curve associated with mastering heat and pressure settings, and considerations regarding the environmental impact of the materials used in the DTF printing process.

| Feature | Description |

|---|---|

| What are DTF Transfers? | A new printing method using a special film to transfer designs to fabrics and surfaces. |

| Benefits | 1. High Quality: Produces vibrant colors and fine details. 2. Versatility: Works on various materials (cotton, polyester, etc.). 3. Ease of Use: User-friendly with standard heat presses. |

| Essential Equipment | A. Printer: Specialized DTF printer (modifications possible). B. Film and Inks: DTF specific for durability. C. Adhesive Powder: Ensures proper adherence during transfer. |

| DTF Transfer Process | 1. Design Creation: Print design on DTF film. 2. Apply Adhesive Powder: Crucial for bonding. 3. Heat Pressing: Transfers design to fabric. |

| Challenges | 1. Initial Costs: Setup can be expensive. 2. Learning Curve: Requires practice. 3. Environmental Concerns: Consider materials’ sustainability. |

| Recent Trends | – Market Expansion: Increased demand for custom apparel. – Online Training: Accessible resources for learning DTF techniques. |

Summary

DTF transfers are an innovative printing technology that’s quickly gaining popularity in the realm of custom printing. They allow for high-quality, vibrant prints on a range of fabrics, making them a versatile option for hobbyists and small business owners alike. Whether you’re looking to create custom clothing or simply want to explore the world of printing, DTF transfers offer a user-friendly solution that could elevate your creative projects. However, it’s important to consider the initial investment required for equipment and the potential learning curve involved. By gaining a deeper understanding of the DTF process, you can successfully harness this exciting technology and enhance your printing capabilities.