DTF Transfers, or Direct-to-Film Transfers, are revolutionizing the world of custom apparel printing by providing an innovative approach to fabric decoration. This cutting-edge printing technique involves creating high-quality designs on a specialized transfer film, allowing for seamless application onto a variety of textiles. As a result, DTF printing is gaining traction among small businesses and established professional printers, thanks to its unmatched vibrancy and durability. With the increasing demand for unique and personalized apparel, the DTF market growth is indicative of its potential to reshape how we think about garment printing. Explore the numerous DTF transfer advantages that make this method a game-changer for both high-volume and boutique print operations.

When we discuss DTF Transfers, we are referring to an advanced method known as Direct-to-Film printing, which has taken the custom printing industry by storm. This technique leverages a unique process to apply detailed graphics to fabric in a way that is both efficient and adaptable. As personalization continues to drive consumer choices, understanding the DTF printing process becomes essential for businesses looking to excel in custom apparel offerings. The versatility of DTF technology not only caters to diverse fabric types but also ensures high-quality results, contributing to burgeoning market trends. By exploring alternative terms and techniques associated with DTF, businesses can fully harness the potential of this dynamic printing method.

Understanding the DTF Printing Process

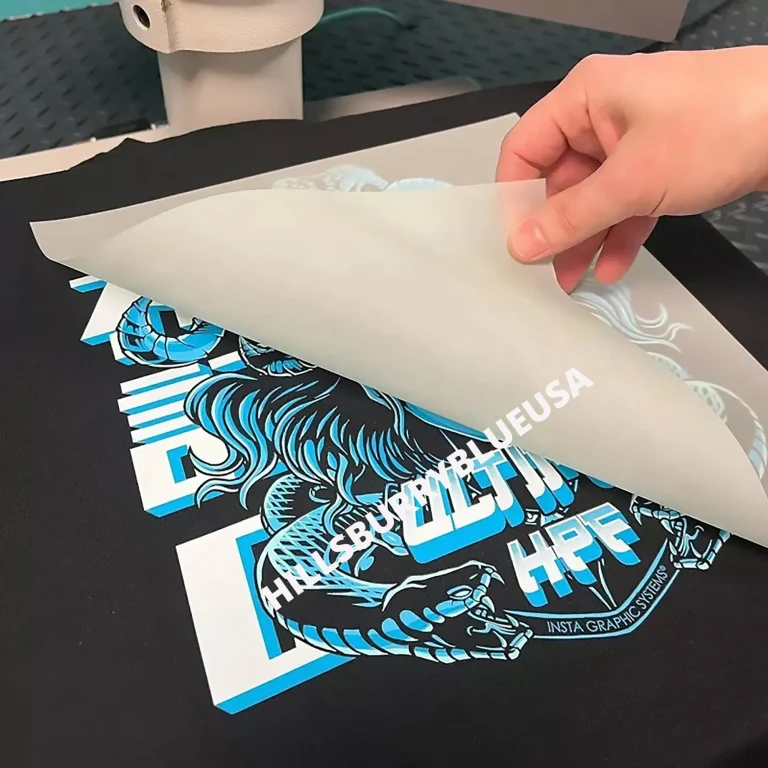

The DTF printing process begins with specialized printers that utilize high-quality inks to print your design onto a PET transfer film. This film acts as a medium, allowing vibrant imagery to be created without the need for extensive setup like traditional screen printing methods. Once the design is printed, an adhesive powder is applied to the wet ink, setting the stage for the transfer process. The application of heat activates the adhesive, melting it to bond the design effectively to the fabric substrate.

What sets DTF apart from other printing techniques is its flexibility. This method allows for small runs without sacrificing quality, making it ideal for custom orders in the apparel sector. Brands can create everything from simple logos to intricate designs on a multitude of fabric types, all while maintaining the vibrant colors and durability DTF is known for. This innovative process empowers businesses to meet diverse customer demands, adapting quickly to the latest fashion trends.

The Advantages of DTF Transfers in Custom Apparel Printing

DTF transfers come with numerous advantages, particularly in the realm of custom apparel printing. One of the most notable benefits is the superior quality and durability of prints. Unlike traditional methods that may fade over time, DTF transfers are designed to withstand multiple washes while preserving their vibrancy. This longevity makes them an excellent choice for fashion-forward brands looking to ensure customer satisfaction.

Additionally, DTF technology is incredibly versatile, allowing transfers to be applied to various fabric types, including cotton, polyester, and polyester blends. This ability to print on a wide range of materials opens the door for creative applications, making it suitable not only for t-shirts and hoodies but also for accessories such as hats and bags. Businesses can explore a broader market by offering personalized and custom apparel items that cater to specific customer interests.

Market Growth and Trends in DTF Printing

The DTF printing market has shown significant growth in recent years, driven by the rising demand for custom merchandise and textile printing solutions. As more businesses recognize the potential of DTF transfers, projections suggest that this trend will continue to escalate through 2025 and beyond. This growth indicates a shift in consumer preferences towards personalized products, prompting businesses to adopt more flexible and efficient printing methods.

The surge in e-commerce and direct-to-consumer sales is also fueling the expansion of DTF technology. Retailers and small businesses can now compete more effectively by offering unique, high-quality custom designs without the need for large inventories. As the DTF market grows, manufacturers are responding with innovations and refinements to printers and materials, further enhancing the capabilities of this printing method and solidifying its place in the textile industry.

Common Challenges Faced in DTF Printing

Despite its advantages, DTF printing is not without its challenges. One common hurdle that businesses encounter is determining the right combination of equipment and materials necessary for optimal results. The quality of the ink, film, and adhesive powder plays a critical role in the effectiveness of the DTF process, and using subpar materials can lead to disappointing outcomes, impacting customer satisfaction.

Additionally, achieving consistent quality in prints can be challenging, especially for beginners who may not have extensive knowledge of the DTF process. Gaining a deep understanding of how different fabrics and designs interact with DTF technology is vital. However, with the right training and experience, many of these challenges can be mitigated, allowing businesses to successfully harness the power of DTF transfers.

Recent Innovations in DTF Technology

In recent years, the DTF printing industry has witnessed several technological innovations that have optimized the printing process. For instance, manufacturers have begun introducing faster printers equipped with advanced technology that not only improve production speed but also enhance color fidelity. This means that businesses can produce higher-quality prints in less time, making DTF an even more attractive option for custom apparel and merchandising.

Moreover, advancements in software solutions have also streamlined the design-to-print workflow, enabling easier adjustments to designs based on customer feedback or emerging trends. As the demand for customized products continues to soar, DTF technology remains at the forefront of meeting these changes, ensuring that businesses can deliver exactly what their customers want with speed and efficiency.

The Future of DTF Transfers in the Textile Industry

Looking ahead, the future of DTF transfers appears bright, with ongoing advancements in technology fueled by market demands. As the popularity of personalized apparel continues to rise, DTF printing will likely play a significant role in meeting consumer expectations for high-quality custom designs. Additionally, as environmentally friendly practices gain traction, innovations in DTF technology may further develop to incorporate sustainable materials and processes.

The adaptability and efficiency of DTF technology makes it a strong competitor in the printing landscape. Businesses that embrace this method will likely find themselves with a competitive advantage as they navigate the evolving demands of the textile industry. Hence, understanding and applying DTF transfers not only serves to enhance product offerings but also positions brands at the forefront of market trends.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film Transfers, involve printing designs on a special transfer film which is then heated to bond the design onto fabric. This method allows for high-quality, vibrant prints on various textiles, making it a popular choice in custom apparel printing.

What are the main advantages of using DTF printing for custom apparel?

The advantages of DTF printing include superior print quality and durability, versatility across different fabric types, and ease of use. This makes DTF Transfers an ideal option for businesses looking to create custom apparel without the complex setups associated with traditional printing methods.

How does the DTF printing process differ from traditional screen printing?

Unlike traditional screen printing, which requires setup and often minimum order quantities, the DTF printing process allows for smaller orders and extensive customization. DTF Transfers are printed onto film and can be applied to different fabrics, streamlining the production process.

What materials can DTF transfers be applied to?

DTF Transfers can be applied to a wide range of materials including cotton, polyester, and cotton blends, making them suitable for various garments such as t-shirts, hoodies, and even hats.

What is driving the growth of the DTF market?

The DTF market is experiencing significant growth due to the rising demand for custom apparel and promotional merchandise. As more businesses adopt DTF Transfers for their efficiency and quality, the technology is gaining traction across both small and large commercial operations.

Are there any challenges associated with DTF printing?

Yes, while DTF printing offers many benefits, challenges include the need for quality equipment and materials. The success of DTF Transfers relies heavily on the quality of inks, films, and powders used, which can affect the final output.

| Key Point | Description |

|---|---|

| Overview of DTF Transfers | An innovative digital printing method for textiles, using a special transfer film. |

| Process Description | Involves printing on PET film, applying adhesive, and using heat to bond designs to fabrics. |

| Advantages | High quality, durability, versatility, and user-friendly processes among key benefits. |

| Market Trends | Growing demand for DTF transfers in custom apparel and promotional merchandise sectors. |

| Challenges | Requires knowledge of equipment and materials for optimal quality outcomes. |

| Recent Developments | Advancements have improved efficiency, color fidelity, enabling quicker adaptations to designs. |

Summary

DTF Transfers have quickly become a staple in the world of textile printing, offering an exceptional blend of quality and versatility that meets the varied demands of today’s market. This modern printing technique leverages innovative methods to produce vibrant designs that are not only eye-catching but also remarkably durable. As businesses continue to seek cost-effective solutions for small orders and custom requirements, DTF Transfers stand out for their user-friendly nature and adaptability to various fabric types. The ongoing advancements in DTF technology promise a bright future, positioning this printing method as a go-to choice for both small entrepreneurs and established firms. Whether in fashion or promotional merchandise, understanding the intricacies of DTF Transfers enhances competitive advantage, making this a critical area of focus as personalization trends evolve in the fabric printing landscape.