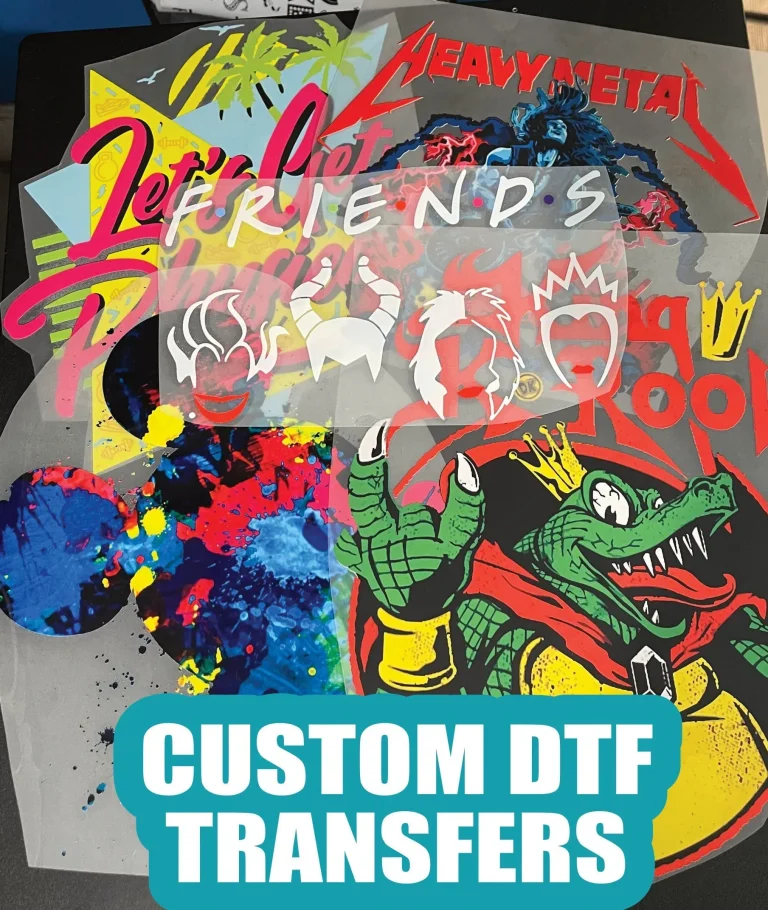

In the vibrant world of custom apparel, DTF transfers (Direct-to-Film transfers) have revolutionized the way designs are printed on clothing. This innovative technique utilizes DTF printing technology to create vivid, high-quality prints that can adhere to a variety of fabrics. Understanding transfer dimensions is crucial, as they directly impact the overall aesthetics and effectiveness of the final product. The benefits of DTF transfers go beyond mere creativity; they offer businesses the chance to deliver personalized designs that resonate with customers. By harnessing this technology, brands can capitalize on the growing demand for custom apparel, ensuring that their designs not only stand out but also meet the market’s evolving needs.

In recent years, the realm of custom clothing has seen a surge in popularity for DTF film prints, often referred to as Direct-to-Film transfers. This method provides an efficient solution for printing intricate designs on garments, appealing to the creativity of designers and brands seeking to differentiate their offerings. The unique aspect of transfer dimensions plays a pivotal role in determining how well these prints come to life on various textiles. As manufacturers increasingly recognize the advantages offered by DTF printing, including its ability to cater to personalized fashion trends, the industry is witnessing an exciting evolution. Understanding the nuances of DTF technology not only enhances product quality but also opens up new avenues for artistic expression and market engagement.

The Advantages of DTF Printing Technology

DTF printing technology has rapidly transformed the landscape of custom apparel production. At its core, this innovative method enables vibrant printing on various materials, making it incredibly versatile for different industries. One of the most significant advantages of DTF transfers is their high durability; prints are designed to withstand multiple washes without losing their vibrancy. This level of resilience is a game-changer for businesses looking to deliver quality products to their customers, establishing trust while ensuring customer satisfaction.

Moreover, DTF printing allows for on-demand production, meaning that businesses can print only what they need, eliminating waste and inventory costs. This flexibility not only caters to seasonal demands but also enables customizations that align with emerging fashion trends. By leveraging DTF technology, companies can stay competitive and relevant, offering unique designs that resonate with target audiences and align with contemporary consumer preferences.

Understanding Transfer Dimensions

The dimensions of DTF transfers are crucial to the success of any printing project. Sizing directly influences the visibility and appeal of the design on the apparel, making it essential for designers to carefully consider these aspects. Common sizes range from 12 to 16 inches for standard t-shirts, which provide a perfect balance—large enough to attract attention while small enough to maintain the garment’s overall aesthetic. Not paying attention to the proper dimensions can lead to prints that appear unbalanced or diminish the garment’s visual impact.

Additionally, the dimensions chosen must align with the specific type of apparel being printed on. For larger items like hoodies or promotional gear, larger transfer sizes are necessary to ensure the design doesn’t get lost. Conversely, smaller items like hats or bags benefit from more compact designs. Thus, understanding the appropriate transfer dimensions is vital for achieving a harmonious design that enhances the wearability of the apparel.

Aesthetic Considerations in DTF Transfers

Aesthetics play a pivotal role in the success of any apparel design, and the dimensions of DTF transfers significantly contribute to a product’s overall appearance. Oversized prints can lead to distortions during application, resulting in less than desirable outcomes that can tarnish a designer’s reputation. Similarly, prints that are too small may fail to make an impact, appearing lost on larger fabrics. Because of these factors, finding the perfect dimension for each design is crucial in maintaining aesthetic appeal.

Furthermore, color contrasts and patterns also depend on the size of the DTF transfer. A correctly dimensioned transfer allows for bold, eye-catching designs that pop against the garment’s fabric. When designers select sizes based on garment dimensions, they create a harmonious blend that enhances the visual experience for the wearer. Thus, thoughtful consideration of transfer dimensions is mandatory in order to achieve the desired aesthetic quality.

Current Market Trends for DTF Transfers

The market for DTF transfers is on a rapid upswing, largely driven by increased consumer demand for customization in apparel. According to recent industry analyses, brands are increasingly adopting DTF technology to meet the evolving fashion trends that prioritize personalization and individual expression. The ability of DTF printing to support a range of design sizes allows businesses to cater to niche markets, fostering brand loyalty while expanding their customer base.

Additionally, companies that effectively utilize DTF transfers position themselves advantageously in the competitive landscape by offering unique, one-of-a-kind products. As more consumers gravitate towards sustainable and ethically-produced clothing, brands adopting DTF technology can fulfill these demands by providing versatile printing solutions that cater to diverse style preferences and trends.

Cost-Effectiveness of DTF Printing

One of the standout features of DTF printing technology is its cost-effectiveness compared to traditional printing methods, such as screen printing. Many small businesses are turning to DTF transfers as a viable solution for custom apparel needs, benefiting from lower startup costs while maintaining high-quality production standards. DTF allows for shorter print runs without incurring significant overhead, thus giving entrepreneurs the flexibility needed to navigate the delicate balance between demand and production.

Moreover, the scalability of DTF printing enhances profitability for businesses; as orders grow, they can increase production seamlessly without needing significant investments in equipment or materials. This adaptability encourages companies to experiment with new designs and explore multiple market niches, ultimately driving increased sales and customer engagement.

Best Practices for DTF Printing Success

To achieve optimal results with DTF printing, following best practices regarding transfer dimensions and procedures is essential. Users are encouraged to conduct test prints prior to finalizing their designs to ensure that the dimensions yield the desired quality. Making adjustments based on fabric type, garment size, and intended graphic is crucial for achieving superior results. Companies should provide training for their teams to understand these best practices, enhancing overall production quality.

Furthermore, utilizing advanced printer settings can offer significant improvements in quality and accuracy of DTF transfers. By fine-tuning dimensions and other critical parameters, businesses can minimize common printing errors and ensure a smoother operational flow. Investing in these best practices will ultimately result in higher quality outputs, customer satisfaction, and increased profitability in the competitive apparel market.

Frequently Asked Questions

What are DTF transfers and how do they work?

**DTF transfers**, or Direct-to-Film transfers, are a printing method that involves transferring designs printed on a special film onto fabrics using heat. The process utilizes DTF printing technology which applies vibrant inks and an adhesive powder to ensure the design adheres well to various materials, making it ideal for **custom apparel**.

What are the benefits of DTF transfers compared to traditional methods?

The **benefits of DTF transfers** include cost-effectiveness, versatility, and the ability to produce vibrant, durable prints. Unlike traditional methods like screen printing, DTF technology allows for on-demand printing, accommodating various design sizes and complexities, which makes it popular for businesses focusing on **custom apparel**.

How do transfer dimensions affect the quality of DTF transfers?

Transfer dimensions are crucial in DTF transfers as they directly impact the aesthetic appeal and quality of the print. For optimal results, dimensions typically range between **12 to 16 inches** for t-shirts. Oversized transfers may lead to distortion while inadequately sized prints can appear diminished, compromising the overall design.

Can I use DTF transfers on any type of fabric?

Yes, **DTF transfers** are versatile and can be applied to a variety of fabrics, including cotton, polyester, and blends. This ability allows businesses to provide **custom apparel** in a range of styles catering to different customer preferences and fashion trends.

What common mistakes should be avoided when working with DTF transfers?

Some common mistakes include not conducting test prints to perfect transfer dimensions and failing to adjust printer settings appropriately for the specific fabric type. These errors can lead to poor-quality results, so understanding the importance of dimensions in DTF transfers is key to ensuring optimal results.

What trends should I watch for in the DTF transfer market?

The DTF transfer market is seeing growth driven by the rising demand for **custom apparel** and sustainability trends. Brands catering to personalized fashion and diverse size needs are gaining traction. Additionally, companies focusing on low startup costs and scalability are increasingly adopting DTF technology to meet customer demands effectively.

| Aspect | Details |

|---|---|

| DTF Technology Overview | DTF (Direct-to-Film) transfers deliver vibrant prints using specialized inks, allowing for printing on various materials and on-demand. |

| Importance of Dimensions | Selecting the right size is critical for visibility, aesthetic appeal, and prevents distortion during the transfer process. |

| Aesthetic Appeal | Oversized designs may distort and appear low-quality, while undersized prints may look insignificant on larger items. |

| Market Trends | The DTF transfer market is growing, fueled by demand for custom apparel, sustainability, and personalization. |

| Cost-Effectiveness | DTF technology offers lower startup costs and better scalability compared to traditional printing methods. |

| Best Practices | Test prints prior to finalizing dimensions, adjust printer settings accordingly to minimize errors. |

Summary

DTF transfers are revolutionizing the custom apparel industry by offering vibrant, durable prints with the potential for high customization. Understanding the significance of dimensions in DTF transfers is essential, as the right size can enhance visibility, aesthetics, and application effectiveness. As the market for custom apparel continues to grow, businesses focusing on providing well-sized DTF transfers will see significant advantages, allowing them to stand out in a competitive landscape.