DTF transfers, or Direct-to-Film printing, are transforming the landscape of custom apparel printing, providing a fresh and innovative solution for businesses looking to stand out. This cutting-edge printing technology is not just about vibrant colors and intricate designs; it embodies the latest printing technology trends that cater to contemporary consumer needs. As the demand for eco-friendly printing solutions rises, DTF innovations are at the forefront, utilizing sustainable materials and practices to minimize environmental impact. In this blog post, we will explore the exciting advancements in DTF transfers that are shaping the future of the industry, including enhanced print quality and operational efficiency. Join us as we delve into how this remarkable technology is revolutionizing the way we create and wear custom designs, while aligning with the growing preference for sustainable fashion.

Direct-to-Film (DTF) transfers represent a significant evolution in the realm of textile printing, introducing a novel approach to customizing apparel. This printing technique has gained traction due to its ability to deliver high-quality images with remarkable detail, making it a favorite among graphic designers and apparel brands alike. Furthermore, innovations within this area prioritize not only aesthetic appeal but also encompass sustainable practices, positioning DTF as a player in the eco-friendly printing movement. As we discuss the future of this unique printing method, we will analyze trends that include the acceleration of production speeds and the rising popularity of personalized goods. Embracing this technology opens doors to dynamic applications across various markets, reflecting a shift toward more innovative and responsible printing methods.

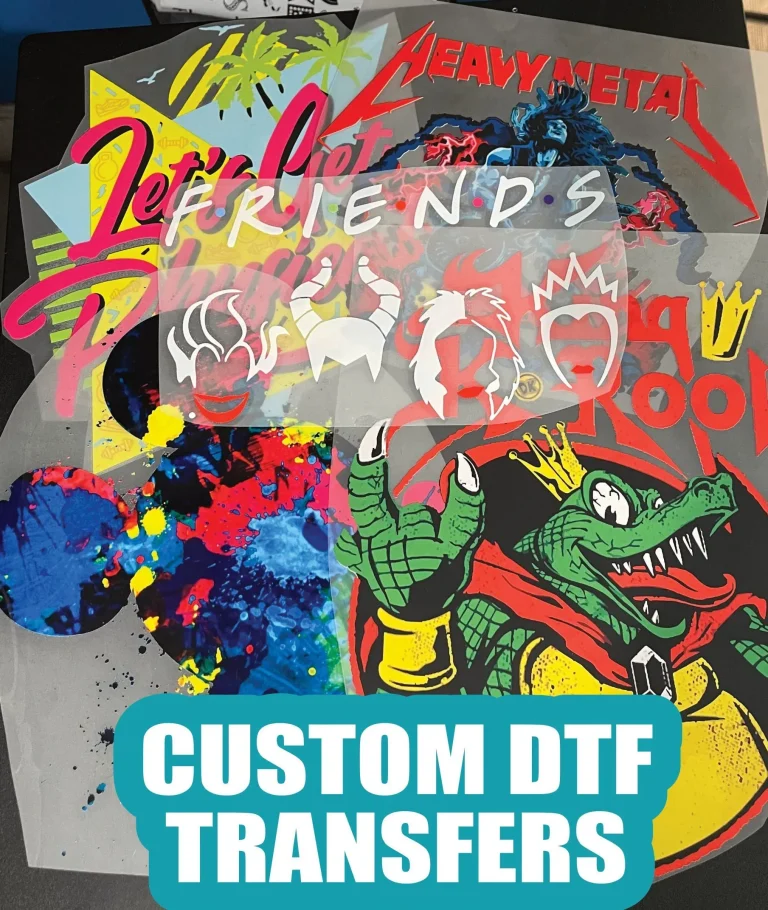

The Advantages of Direct-to-Film Printing

Direct-to-Film (DTF) printing offers several advantages that set it apart from traditional printing methods. Its technique allows for high-quality images that maintain vibrancy and detail, even on diverse fabric types. The process utilizes specially formulated inks that bond well with the film and substrate, offering exceptional durability and wash-resistance. This quality makes DTF an ideal choice for custom apparel printing, where the visual appeal and longevity of designs are paramount.

In addition to print quality, DTF’s versatility is a significant advantage. It can be used on various materials such as cotton, polyester, and blends, allowing businesses to expand their offerings. This flexibility is key in today’s market, where brands seek to differentiate themselves with unique products. As DTF innovations continue to evolve, expect to see even more varied applications, further cementing its position in the printing landscape.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, involve a printing technology that allows designs to be printed onto a special film and then transferred onto a fabric. This process utilizes advanced digital printers and unique inks, which enhance color quality and detail, making it ideal for custom apparel printing.

What are the latest trends in DTF Transfers for eco-friendly printing?

Recent trends in DTF Transfers demonstrate a strong shift towards eco-friendly printing practices. Manufacturers are increasingly adopting water-based inks and sustainable substrates to reduce their environmental footprint, aligning with consumer demand for green products and compliance with stricter environmental regulations.

How do DTF innovations improve print quality?

DTF innovations focus on improving print quality through advanced ink formulations that achieve higher color fidelity and resolutions. These advancements allow for vibrant colors and smoother gradients, catering to brands aiming for top-notch quality in their custom apparel printing.

Can DTF Transfers support personalization and customization?

Yes, DTF Transfers excel in customization and personalization, enabling businesses to efficiently handle small batch orders with intricate designs. This capability meets the growing consumer demand for unique products and personalized apparel, positioning DTF as a leader in custom apparel printing.

What is the significance of speed and efficiency in DTF Transfers?

Speed and efficiency are crucial in DTF Transfers, as modern printers leverage automated systems to significantly reduce turnaround times. This allows businesses to meet high-volume orders quickly, maintaining competitiveness in the printing technology landscape.

What is the future outlook for the DTF Transfers market?

The future outlook for the DTF Transfers market is promising, with predictions of a compound annual growth rate (CAGR) of around 10%. This growth is largely driven by DTF’s versatility, expanding applications across various industries beyond textiles, including packaging and promotional products.

| Key Trend | Description |

|---|---|

| Improved Print Quality | Advancements in ink formulation leading to higher resolutions and vibrant colors. |

| Speed and Efficiency | Incorporation of automation and high-speed printing to reduce turnaround times. |

| Eco-Friendly Solutions | Use of water-based inks and sustainable substrates to meet environmental standards. |

| Integration with Digital Technologies | AI and machine learning enhancing operational efficiencies and reducing waste. |

| Customization and Personalization | Facilitating small batch orders and unique designs to meet consumer demands. |

| Market Growth and Expanding Applications | CAGR of approximately 10%, with applications expanding into packaging and promotional products. |

Summary

DTF Transfers are at the forefront of innovation in the printing industry, shaping the way businesses approach apparel and textile customization. As we explore the latest trends, it’s clear that improvements in print quality, speed, and eco-friendliness are paving the way for a sustainable future. The integration of digital technologies and the ability to meet consumer demands for personalization further highlight the versatility of DTF transfers. This evolution promises not just growth in the market but also a shift toward more responsible and innovative printing practices, marking DTF transfers as a key player in the dynamic landscape of printing technology.