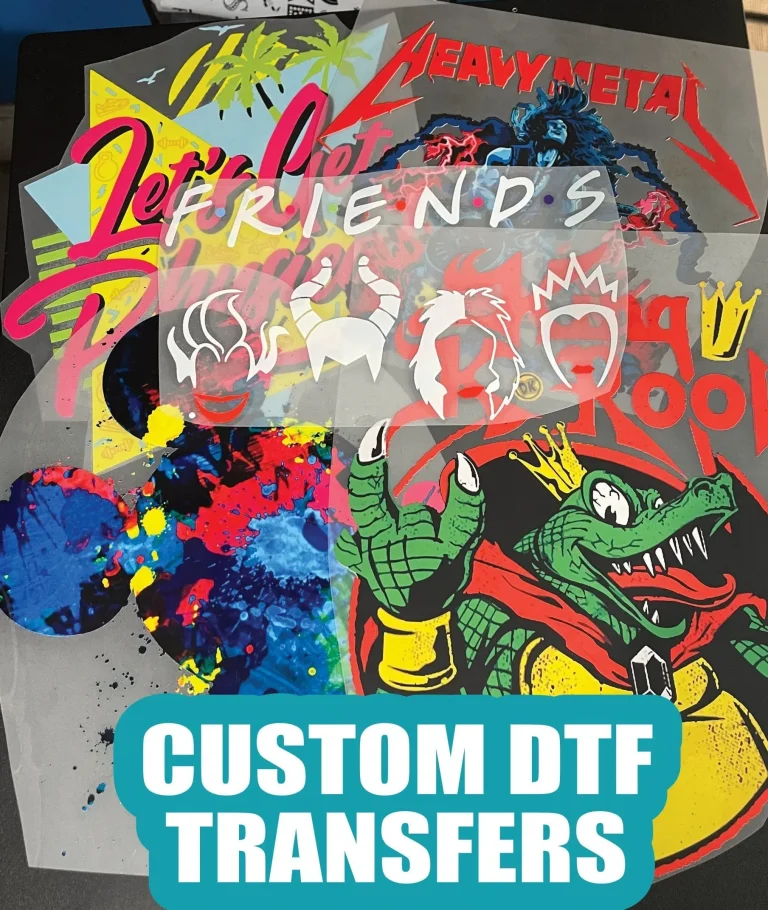

DTF transfers, or Direct to Film transfers, have emerged as a game changer in the world of custom apparel and textile printing. This innovative printing process allows for vibrant and durable designs to be applied to a variety of fabrics, providing endless possibilities for creators and businesses alike. With the best DTF transfers, you can elevate your merchandise, whether it’s for promotional events or personal projects. Understanding DTF transfer sizes is crucial for achieving the perfect balance between design intricacy and garment fit. Additionally, the rise of sustainable DTF transfers ensures that as you customize apparel, you also contribute to eco-friendly practices in the industry.

In the dynamic landscape of textile decoration, techniques such as Direct to Film (DTF) printing are revolutionizing how designs are applied to garments. This method employs unique films and adhesive powders, resulting in rich, vibrant prints suitable for various fabrics. When discussing custom fabric applications, the emphasis on the versatility of DTF processes captures the imagination of many designers. As the printing technology advances, custom apparel creations expand beyond traditional boundaries—leading to more intricate and precise designs. Simultaneously, the industry is witnessing a shift towards environmentally responsible production through sustainable transfer methods.

The Impact of DTF Transfer Sizes on Custom Apparel

When it comes to creating custom apparel, the size of your DTF transfer can profoundly influence not only the aesthetic appeal but also the functionality of your designs. Larger DTF transfers allow for more intricate and detailed visuals, which are essential for making bold statements on t-shirts or hoodies. However, smaller sizes play a critical role in applications where precision matters—such as on children’s clothing or promotional items where the artwork needs to fit specific areas without overwhelming the garment.

Understanding the nuances of DTF transfer sizes helps in tailoring designs to suit different garment types efficiently. For instance, a large graphic may enhance visual impact on adult apparel, whereas a smaller transfer could be well-suited for accessories like hats or bags. It’s crucial to align the size of the DTF transfer with your project goals, ensuring that designs not only capture attention but also maintain clarity and professionalism.

Best DTF Transfers for Quality and Durability

Selecting the best DTF transfers hinges on a combination of factors like material quality and supplier reliability. High-quality DTF films and superior adhesive powders contribute significantly to the durability and vibrancy of the prints. Look for reviews and testimonials from consumers who have tried a variety of products; they often highlight which brands provide the best outcomes in washability and overall print quality.

Moreover, investing in premium DTF transfers may incur a higher initial cost, but the result is longer-lasting prints that can withstand various conditions without fading or peeling. Therefore, your focus should not only be on price but also on the long-term performance and satisfaction that these transfers can yield for your custom apparel projects.

Understanding the DTF Printing Process

The DTF printing process is a streamlined method that allows for sending vibrant designs directly onto film, which is subsequently transferred to fabric using heat and pressure. This method embodies flexibility, enabling the use of different substrates, including cotton, polyester, and blends. An understanding of this process is crucial for those venturing into custom apparel, as it dictates the design’s richness and adherence to various fabric types.

Furthermore, the DTF printing process innovatively bridges the gap between direct-to-garment (DTG) and heat transfer printing, offering a broader spectrum of creative possibilities. The efficient transfer process ensures that colors remain vivid and intact even after multiple washes, reflecting the growing demand for high-quality textile printing methods in the apparel industry.

Sustainable Practices in DTF Transfers Today

Sustainability has become a pivotal concern across all sectors, including custom apparel. In response, many manufacturers have begun to adopt eco-friendly inks and biodegradable films in the DTF transfer process. This not only caters to environmentally conscious consumers but also showcases a brand’s commitment to responsible practices within the textile industry.

By choosing sustainable DTF transfers, businesses not only contribute to reducing their carbon footprint but also establish a positive brand reputation. Consumers today are more inclined to support companies aligned with eco-friendly values, making sustainability not just a trend but a necessity in the evolving landscape of custom apparel production.

Choosing the Right Suppliers for DTF Transfers

The choice of supplier can significantly impact the quality of DTF transfers. It’s essential to conduct thorough research on potential suppliers to ensure they are reputable and provide a range of sizes and materials that suit your project needs. A trusted supplier will likely offer transparent feedback from clients, which can guide your decision-making process.

Additionally, supplier support plays a crucial role—many top-tier suppliers provide resources, including design templates and customer service, to help you navigate your DTF transfer selections effectively. Establishing a partnership with a reliable supplier can lead to a smoother production process and higher levels of satisfaction for your custom apparel endeavors.

Trends Shaping the Future of DTF Printing

Keeping pace with emerging trends in DTF printing can provide a competitive edge in the custom apparel market. Recent technological advancements have led to notable improvements in printing resolution and efficiency, allowing for quicker production times without sacrificing quality. This is particularly advantageous for businesses looking to fulfill large orders or meet urgent deadlines.

Moreover, the integration of advanced technologies, such as automation in the DTF printing process, enhances productivity while maintaining high standards of precision. Staying informed about these trends not only enables you to leverage the latest tools but also ensures that your offerings remain relevant and appealing to consumers in an ever-evolving marketplace.

Frequently Asked Questions

What are the benefits of using the best DTF transfers for custom apparel?

The best DTF transfers offer vibrant colors, durability, and versatility, making them ideal for custom apparel. They can adhere to various fabrics like cotton and polyester, ensuring that designs maintain their quality and clarity after multiple washes. Additionally, DTF transfers allow for intricate designs, catering to businesses of all sizes looking to create unique personalized items.

How does the DTF printing process work for custom apparel?

The DTF printing process involves printing a design onto a specialized film, which is then coated with an adhesive powder. This film is heat-pressed onto the garment, allowing the design to transfer onto the fabric. This method ensures that designs are not only vibrant and bold but also durable, making DTF transfers a popular choice for custom apparel across different textiles.

What sizes do DTF transfers come in for various projects?

DTF transfers are available in a variety of sizes to accommodate different project needs. Larger transfers are suitable for bold graphics on t-shirts, while smaller sizes work well for intricate designs or tighter areas, like sleeves. It’s essential to select the right size based on garment dimensions and design complexity to achieve the best results.

Why should I consider sustainable DTF transfers for my printing needs?

Sustainable DTF transfers utilize eco-friendly inks and biodegradable films, aligning with a growing demand for environmentally responsible printing practices. By choosing sustainable options, you contribute to reducing environmental impact while appealing to eco-conscious consumers. This not only enhances your brand image but also promotes a positive approach in the custom apparel industry.

What materials are best for high-quality DTF transfers?

For high-quality DTF transfers, it’s crucial to use premium films and adhesives that ensure vivid prints and durability. Established suppliers typically offer high-grade materials that improve washability and comfort. Opting for well-reviewed brands helps ensure you receive the best quality for your custom apparel projects.

How do I choose the right supplier for DTF transfers?

When selecting a supplier for DTF transfers, consider their reputation and customer reviews. Ensure they offer a range of sizes and materials to meet your project’s needs. Research their processes and product quality through case studies and testimonials to ensure reliability and satisfaction for your custom apparel printing requirements.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers are a printing method that involves transferring designs from a film onto textiles using an adhesive powder, resulting in durable and vibrant prints. |

| Versatility of DTF Transfers | DTF transfers can be used for various textile types, making them ideal for custom apparel for both small businesses and larger events. |

| Importance of Size | The size of the transfer affects design details; larger transfers are better for bold graphics, while smaller ones are suited for intricate designs. |

| Factors for Choosing Size | Garment size, design complexity, and customization options should guide the selection of transfer size. |

| Material Quality | Using high-quality films and adhesive powders leads to lasting prints and better color vibrancy. |

| Selecting Reliable Suppliers | Researching manufacturer reputation and verifying material offerings are crucial in choosing the right supplier. |

| Sustainability Trends | There is a growing move towards sustainable practices using eco-friendly inks and biodegradable films in DTF printing. |

| Technological Advancements | Recent innovations have improved DTF printing in terms of resolution and speed, offering competitive advantages. |

Summary

DTF Transfers play a vital role in shaping high-quality custom apparel projects, emphasizing the significance of size in maximizing design impact and usability. By understanding the nuances in printing size, selecting top-notch materials, and partnering with reputable suppliers, businesses can enhance their product offerings and cater to diverse consumer needs. The integration of sustainable practices and advancements in technology further underscores the importance of staying current with industry trends, positioning DTF transfers as a reliable choice for anyone looking to make their mark in the textile printing arena.