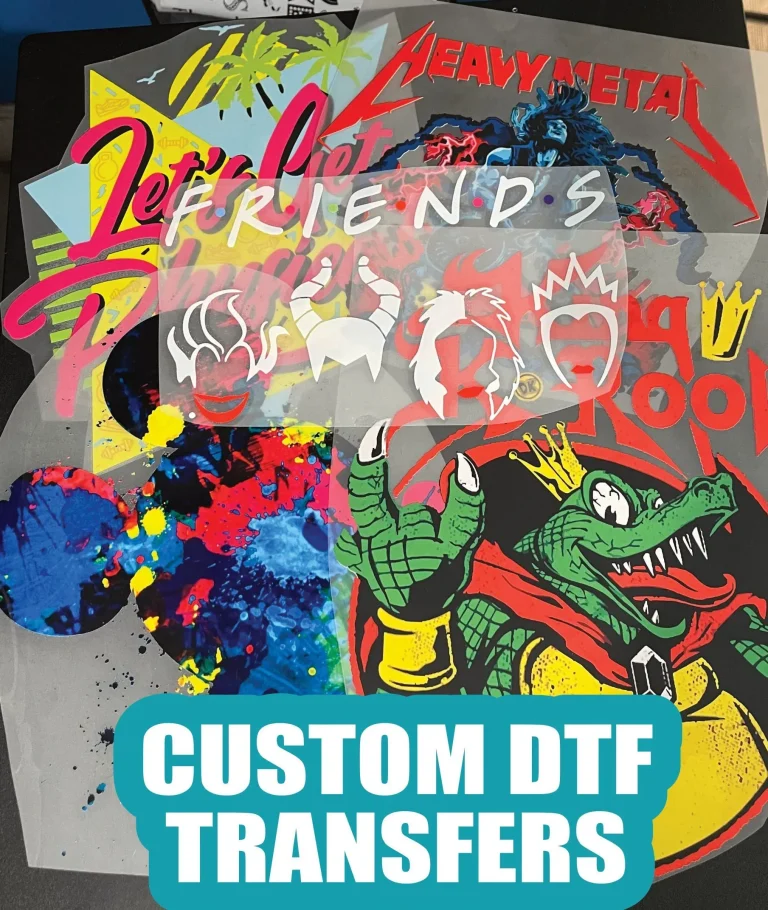

DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry by allowing designers to create stunning, durable prints on a variety of fabrics. As this technology gains traction, understanding the nuances of DTF transfer sizes becomes essential for achieving visually appealing clothing products. The size of a DTF transfer not only influences the design’s integrity but also affects the overall aesthetic and durability of the final garment. With advancements in DTF technology, designers now have the tools to optimize their designs with precise DTF sizing guidelines, ensuring maximum impact. In this exploration, we will delve into the importance of selecting the right size, its impact on design optimization, and how to leverage cutting-edge advancements to elevate your custom apparel printing efforts.

Direct-to-Film printing, often referred to as DTF printing, has transformed the landscape of custom clothing production by offering vibrant and long-lasting designs. This innovative method utilizes film to capture intricate graphics that, when applied using heat, adhere seamlessly to fabric. Understanding the different DTF transfer sizes is crucial for designers seeking to maintain the quality and appearance of their products. Accurate sizing not only enhances the visual appeal of the apparel but also aligns with recent DTF technology advancements that assist in adapting designs to various textile types. Whether you’re crafting sportswear or casual outfits, mastering the art of DTF design optimization is key to achieving standout results in the competitive apparel market.

Understanding DTF Transfer Sizes

When delving into the specifics of DTF transfers, understanding the optimal sizes for various design types is crucial. The size of the transfer not only impacts the visual aesthetics but also the functional applicability on different garments. A small logo transfer might be ideal for caps and t-shirts, while larger designs are better suited for hoodies or back prints. Recognizing the standard sizes ranging from 3 inches for small logos to up to 20 inches for detailed graphics can help streamline the design process, aligning your creations with industry standards. Custom apparel printing heavily relies on such sizing knowledge, ensuring that the final product meets both professional and consumer expectations.

Moreover, adhering to these sizing guidelines ensures that the integrity of your artwork is maintained. For instance, a transfer that’s either too small or oversized can distort your design, leading to potential dissatisfaction among customers. Designers should also consider the fabric and fit of the garment, adjusting transfer sizes accordingly for optimal visibility and appeal. By mastering DTF transfer sizes, you can enhance the aesthetic value of your products in the competitive custom apparel market.

DTF Technology Advancements for Optimal Sizing

The evolution of DTF technology plays a pivotal role in optimizing transfer sizes. With advancements in printing techniques, designers now benefit from enhanced printing capabilities, including greater resolution and color vibrancy that adjust seamlessly with size variations. These technological progressions enable small designs to retain their integrity even when printed on larger canvases, ensuring that the details remain sharp and visually appealing. This flexibility empowers designers to explore more creative avenues while maintaining brand integrity and design health.

In particular, automated sizing software has revolutionized the approach to designing and printing DTF transfers. By leveraging algorithms based on garment dimensions, designers can automate the transfer sizing process, reducing human error and enhancing efficiency. This technology ensures that the final prints are tailored perfectly to match the apparel size, leaving little room for guesswork. Such advancements illustrate the incredible potential of DTF technology and encourage designers to push creative boundaries while ensuring that the transfer sizes are set for maximum impact and durability.

Design Optimization Techniques for DTF Transfers

To achieve stellar results in DTF printing, design optimization is integral. This process involves adapting your designs to fit both the chosen transfer size and the garment’s unique features. For example, intricate details can be lost if a design is scaled incorrectly; therefore, designers must utilize effective visualization techniques to ensure that every aspect of the design remains distinct after the transfer process. Employing vector graphics can help maintain design quality at varying sizes since vectors are resolution-independent and can scale without compromising appearance.

Additionally, taking into account fabric types plays a critical role in DTF design optimization. Depending on whether you’re dealing with cotton, polyester, or blended fabrics, the design’s opacity and detail may vary significantly once transferred. Testing designs on sample fabrics while tweaking sizes and optimizing prints based on the material is crucial for achieving quality results. As such, embracing these strategies greatly enhances the overall effectiveness of DTF transfers and assists in creating apparel that stands out in the market.

Common Sizing Guidelines for DTF Transfers

When approaching DTF transfer sizing, adhering to common guidelines ensures a more streamlined workflow and better-quality outcomes. Typical recommendations suggest that logos are effectively placed within a 3-4 inch range, while larger graphics, such as back designs, should ideally span between 16-20 inches. These guidelines are rooted in the relationship between design size and garment type, emphasizing the need to create a harmonious visual balance that captures attention without overwhelming the apparel.

Designers should always assess the type of garment when determining transfer sizes. For fitted t-shirts, a smaller transfer might suffice, whereas a loose-fit hoodie could benefit from a larger design for greater visibility. Keeping these sizing conventions in check not only simplifies the design process but also equips designers with a strategic approach to meet varying garment requests in the custom apparel sector. This aspect of DTF transfer sizing invites creativity while ensuring that standards remain high.

Fabric Considerations for DTF Transfer Sizes

Selecting the appropriate size for DTF transfers necessitates a thorough understanding of fabric considerations. Different fabrics react uniquely during the printing and transfer process, often necessitating adjustments in design sizing to ensure proper adherence. For instance, stretchy fabrics like spandex may require slightly smaller transfers to accommodate the fabric’s movement without resulting in cracking or peeling over time. It’s imperative for designers to familiarize themselves with the fabric properties to prevent potential design failure post-transfer.

Additionally, the wear and tear of a garment can affect how well a transfer holds up on various materials. A transfer designed for softer, plush fabrics may perform poorly on a thicker, rugged fabric. Thus, it’s important for designers to experiment with transfer sizes on specific fabric types before finalizing their designs. An understanding of these material behaviors enhances the likelihood of producing durable and visually striking printed apparel, making fabric considerations an essential step in the DTF printing process.

Testing DTF Transfer Sizes in Production

Testing is a vital phase in the DTF transfer production process, particularly for sizing. By creating sample garments with different transfer sizes, designers can observe firsthand how variations in size influence the overall outcome. This practical approach allows designers to gauge how a design holds up under heat and pressure, simulating real-life conditions, which is essential in ensuring high-q uality end products. The trial-and-error method not only validates the chosen sizes but also reveals insights that can significantly enhance future designs.

Moreover, implementing rigorous testing procedures can aid in creating a feedback loop where performance metrics of various sizes can be tracked and improved. This data-driven approach ensures that designers remain responsive to the market’s needs while fine-tuning their process to deliver consistently high-quality results. Ultimately, thorough testing of DTF transfer sizes serves as a quality assurance measure, enabling designers to bring forth exceptional and reliable custom apparel that customers will appreciate.

Frequently Asked Questions

What are the recommended DTF transfer sizes for custom apparel projects?

When working with DTF transfers, recommended sizes typically range from 3-4 inches for small logos to 16-20 inches for larger back prints. Ensuring that the DTF transfer size corresponds with the garment dimensions is crucial for achieving a visually appealing and professionally finished product.

How does DTF technology advancements impact the sizing of transfers?

Advancements in DTF technology, such as improved ink formulations and automated sizing software, have made it easier for designers to determine the optimal transfer sizes. These innovations allow for automatic adjustments based on garment dimensions, enhancing the visual appeal and longevity of designs.

What guidelines should I follow for DTF sizing optimization?

For DTF sizing optimization, it’s essential to maintain proportionality between the transfer size and the apparel. Common guidelines suggest that small designs, like logos, should be 3-4 inches, while larger artwork should span up to 16-20 inches, ensuring a well-balanced layout on the garment.

Why is proper sizing important for DTF transfers on different fabrics?

Choosing the correct DTF transfer size is vital as different fabrics behave differently. For example, stretchy materials require a well-fitted transfer that allows for movement without compromising the design’s integrity, thus preventing issues like peeling or cracking.

How can I test the size of my DTF transfers before production?

Testing various DTF transfer sizes on sample garments is recommended. This trial-and-error approach allows you to visualize how each size responds to heat and pressure, ensuring that the final pieces meet quality standards before mass production.

What common mistakes should be avoided when determining DTF transfer sizes?

Common mistakes include choosing sizes that are either too small, which can lose detail, or too large, leading to peeling and cracks. It’s critical to ensure the DTF transfer size aligns with both the design intent and the garment’s dimensions for optimal results.

| Aspect | Key Points |

|---|---|

| DTF Transfer Definition | A method for creating designs on fabric by printing images onto a specialized film, then transferring them using heat and pressure. |

| Significance of Size | The size of the DTF transfer affects the aesthetic appearance and durability of the design. |

| Size Optimization | An ideal transfer size enhances visual appeal and avoids issues like peeling or cracking. |

| Common Sizing Guidelines | Transfers typically range from 3-4 inches (small designs) to 16-20 inches (large artworks). |

| Material Considerations | Fabric type can influence size selection; stretchy fabrics may require size adjustments for proper adhesion. |

| Testing Importance | Testing various sizes on samples is essential to ensure quality and adhesion before mass production. |

| Technological Advances | Advancements in inks, adhesives, and automated sizing software improve design quality and production efficiency. |

Summary

DTF transfers are a crucial element in the world of custom apparel, and understanding their sizing can significantly enhance the quality of your designs. By carefully considering the size of your DTF transfers, you can optimize the visual impact of your artwork while maintaining durability and relevance to the fabric of the garment. Embracing technology and following best practices in sizing will ensure your prints are not only vibrant but also last long, catering to a market that demands both style and functionality.