DTF transfers have revolutionized the realm of custom apparel printing, offering an effective way to bring your unique designs to life. This innovative technique, known as Direct-to-Film printing, allows for vibrant, high-quality prints that adhere well to various fabric types. When selecting DTF transfers, it’s crucial to consider factors like transfer size and quality to ensure your designs not only look great but also last through multiple washes. With increasing demand for personalization in clothing, mastering DTF transfer techniques is essential for anyone looking to stand out in the competitive world of fashion. Join us as we delve deeper into the advantages of DTF transfers and how to choose the best options for your projects.

Also referred to as Direct-to-Film printing, DTF transfers are a prominent choice for many custom apparel creators due to their flexibility and ability to produce intricate designs. This technique utilizes a special printing process that allows for high-resolution images to be effectively transferred onto fabrics. The rising trend in personalized clothing solutions has led to a surge in interest surrounding DTF applications, including important criteria such as DTF transfer size and overall quality. By understanding the nuances associated with selecting the right type of transfer, creators can ensure that their designs maintain the desired aesthetic and durability. This guide aims to illuminate the key aspects of DTF technology and its impact on modern design methodologies.

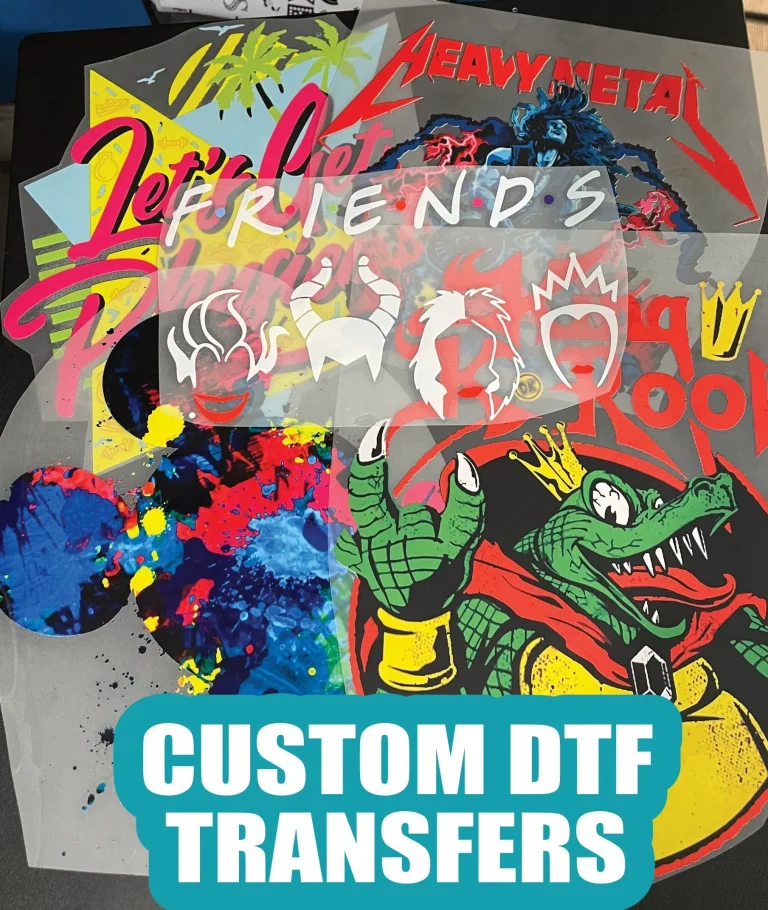

Choosing the Right DTF Transfers for Your Project

When embarking on your custom apparel printing project, selecting the right DTF transfers is a crucial step that can impact the final outcome significantly. DTF transfers are popular due to their ability to create vibrant, high-quality designs that can adhere to various fabric types. Understanding the specific requirements of your project, such as design complexity and fabric choice, will help you choose transfers that match these needs. It’s essential to research various suppliers and compare their offerings based on quality, which is influenced by factors like the film used and the printing technology employed.

Additionally, considering the size options available for DTF transfers is vital. For intricate designs, the transfer size must accommodate all elements without sacrificing detail. Many suppliers offer both standard and custom sizes, and knowing which option best suits your artwork will enhance the aesthetics and fit of the final product. Remember, investing time in selecting the appropriate DTF transfers can lead to a more polished and professional result in your custom apparel project.

The Importance of DTF Transfer Quality

Quality is paramount when it comes to DTF transfers. The longevity and visual appeal of your printed apparel hinge upon the transfer’s quality. Premium DTF films allow for sharper images and colors that truly pop, which is essential for making your designs stand out. Moreover, high-quality DTF transfers ensure that the designs are durable, maintaining their vibrancy and integrity through multiple washes. When evaluating transfer quality, focus on details such as adhesive strength and the underlying printing process that produces the final product.

Furthermore, not all DTF transfers are created equal in terms of adhesion properties. Transfers that utilize advanced printing technologies typically offer superior results, ensuring that your designs adhere strongly to various fabrics. By prioritizing these factors, you can guarantee that the finished apparel not only looks great but also lasts long-term, providing value for your investment in custom printing.

Exploring DTF Transfer Size Options

The size of your DTF transfers plays a critical role in the overall success of your custom apparel project. Each design has unique dimensions that must be accurately assessed to ensure a perfect fit. Larger designs can be visually striking, but they also require careful scaling to maintain the quality and integrity of the artwork. Before you order your DTF transfers, take the time to measure your garment and determine the optimal size for your design.

Additionally, suppliers often provide both standard and custom sizing options for DTF transfers. While standard sizes may be convenient, custom sizes can provide a tailored solution that aligns perfectly with your specific requirements. This flexibility can significantly enhance how your designs are viewed and appreciated on the apparel, ensuring that every detail is prominently displayed. Choose wisely, as the right size choice will elevate your custom printing project.

Understanding DTF Transfer Adhesive Types

The adhesive type used in DTF transfers is another aspect that significantly influences the final result. Water-based adhesives are highly favored for their environmentally friendly properties and soft feel against the fabric. They work exceptionally well on cotton and polyester blends, making them a great choice for a wide range of apparel. These types of adhesives allow the fabric to maintain a pleasant hand feel while ensuring the printed design stays intact through numerous washes.

On the other hand, plastic-based adhesives might provide enhanced durability, but they can feel stiffer against the fabric. When making your selection, consider the intended use of the apparel and the overall user experience. For example, if the clothing is meant for active wear, choosing an adhesive that allows for flexibility might be more beneficial. Understanding the distinction between these adhesive types will aid you in picking the right DTF transfers for your custom apparel.

Ensuring Fabric Compatibility with DTF Transfers

Each fabric reacts differently to printing methods, making fabric compatibility a crucial consideration when using DTF transfers. While many DTF transfers work seamlessly with cotton and polyester, not all transfers are suitable for every type of fabric. It’s important to verify that the DTF transfer you select explicitly states compatibility with your chosen materials. This ensures that the integrity of both the design and the fabric is preserved throughout the printing process.

The flexibility of the fabric is another vital factor to take into account. Some DTF transfers are designed specifically for stretchy fabrics, which is ideal for athletic wear or fitted garments. Others are more suited for rigid textiles, providing a different aesthetic and feel. By ensuring that your DTF transfers are compatible with your fabric, you can achieve excellent results that enhance the overall quality of your custom apparel.

Budgeting for Your DTF Transfer Project

Cost considerations play a significant role in executing a successful DTF transfer project. Prices can vary widely based on the quality, size, and complexity of the transfers, making it imperative to conduct thorough research before making a purchase. Comparing multiple suppliers not only helps in finding the best deals but also allows you to gauge the overall quality of their offerings. Keeping a well-defined budget is essential, as it ensures you make informed decisions that align with your financial capabilities.

Additionally, exploring bulk purchase discounts can also yield significant savings if you’re planning a larger project. Many suppliers offer competitive pricing incentives for bulk orders, making it more affordable to order higher quantities of DTF transfers. This can be particularly advantageous for small businesses looking to scale their operations. Being cost-conscious while canvassing for the best quality will ultimately result in a successful and profitable custom printing project.

Frequently Asked Questions

What should I consider when selecting DTF transfers for custom apparel printing?

When selecting DTF transfers for custom apparel printing, key factors include transfer quality, size options, adhesive types, and fabric compatibility. High-quality DTF printing ensures vibrant designs that last through multiple washes. It’s also essential to choose the right size for your designs, looking for standard or custom options as needed.

How does the size of DTF transfers affect the final product?

The size of DTF transfers is crucial as it impacts the visual integrity of your design on apparel. Understanding the maximum dimensions for DTF transfer sizes ensures that your artwork scales properly. Opting for custom sizes when necessary is beneficial for achieving a perfect fit on your chosen garments.

What are the benefits of high-quality DTF transfers?

High-quality DTF transfers offer superior adhesion, vibrant colors, and durability. These transfers maintain their appearance after multiple washes, preventing fading and peeling. Investing in quality DTF printing results in visually appealing apparel that stands up to wear and tear.

How do different adhesive types impact DTF transfers?

The adhesive type in DTF transfers greatly affects their effectiveness and feel on fabric. Water-based adhesives are environmentally friendly and offer a soft touch, suitable for many fabrics, while plastic-based adhesives provide extra durability but may feel stiffer. Choose the adhesive based on your project requirements and user comfort.

Can all fabrics be used with DTF transfers?

No, not all fabrics are compatible with DTF transfers. It is essential to check that the transfer you choose is designed for your specific fabric type. Common choices include cotton and polyester, with some transfers specifically made for stretchy materials suitable for athletic wear.

What should I keep in mind regarding the cost of DTF transfers?

Cost is a vital consideration when purchasing DTF transfers. Prices can vary based on quality and size. It’s advisable to shop around, and if you’re executing larger projects, inquire about bulk purchase discounts to maximize your budget while ensuring you select quality transfers.

| Key Point | Details |

|---|---|

| Introduction | DTF transfers offer vibrant printing and versatility on various fabrics. |

| Quality of Transfers | Look for superior adhesion and high-resolution printing for durability. |

| Size Options | Consider standard and custom sizes based on your design. |

| Adhesive Types | Water-based for softness; plastic-based for durability. |

| Fabric Compatibility | Ensure transfers are compatible with the fabric type and flexibility needed. |

| Supplier Reputation | Research reviews and request samples to ensure quality. |

| Cost Considerations | Prices vary, so compare options and inquire about bulk discounts. |

| Printing Equipment | Ensure your printer and heat press are compatible with DTF transfers. |

| Recent Developments | Emphasis on eco-friendly solutions and user engagement in design. |

Summary

DTF Transfers are revolutionizing the custom printing industry by offering high-quality solutions that are tailored to various fabric types. When selecting DTF transfers, it is essential to consider key factors such as transfer quality, size options, adhesive types, fabric compatibility, and supplier reliability. By addressing these considerations and staying updated on the latest industry trends and innovations, you can maximize the impact and durability of your designs. With the right approach, your DTF printing projects will not only meet but exceed expectations, delivering exceptional results that stand the test of time.