DTF transfers, short for direct to film transfers, are revolutionizing the custom printing industry with their unmatched versatility and production of high-quality prints. As a leading technology for garment decoration, understanding the intricacies of DTF printing, such as size selection and the impact of DTF printing quality, is crucial for anyone looking to make an impression. This innovative approach allows artists and businesses to achieve vibrant and durable designs that withstand the test of time. In this blog post, we will explore key insights on effective DTF transfer techniques to maximize print quality and enhance overall satisfaction. From selecting the appropriate size to ensuring the finest DTF printing quality, our overview aims to guide you in harnessing the full potential of this exceptional printing method.

Direct to film printing, commonly known as DTF printing, represents a significant advancement in the world of textile printing techniques. This method promotes the transfer of designs onto garments through a unique process that not only guarantees high vibrancy but also ensures longevity and durability of the prints. Understanding the nuances of size selection DTF is essential for achieving detailed and clear designs, helping to maintain the integrity of the artwork as it is applied to various fabrics. By leveraging cutting-edge DTF transfer techniques, individuals and businesses can elevate their printing game, ensuring that the outcomes resonate with both aesthetic appeal and professional quality. In this discussion, we will delve into the essentials of high-quality DTF, highlighting the best practices and considerations for optimal results.

The Evolution of DTF Transfers in Custom Printing

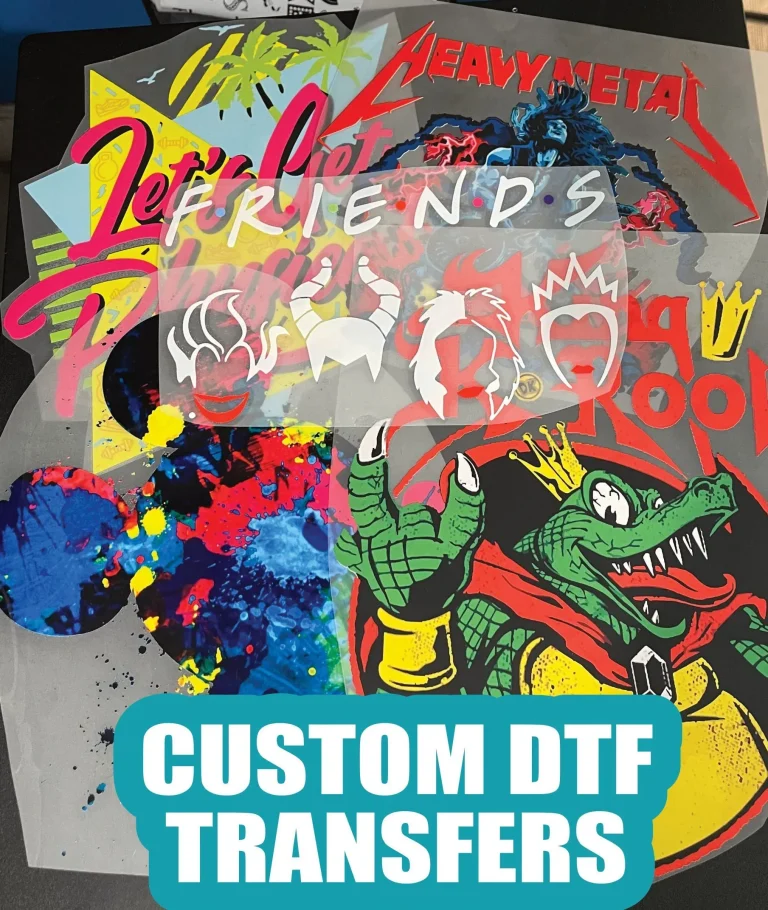

DTF printing, or Direct to Film transfer printing, marks a significant advancement in custom printing technology. This technique, which rose to prominence in recent years, is noted for its versatility and ability to produce high-quality, vibrant prints on a variety of garments. The evolution of DTF transfers is largely attributed to advancements in printing technology and material science, which have made it easier for businesses to create stunning designs with remarkable durability. As more print entrepreneurs recognize the potential of this technique, DTF transfers are becoming a standard in the industry.

The success of DTF transfers is rooted in their operational flexibility; printers can handle complex graphics and a wide color spectrum, which appeals to artistic and creative enterprises. Moreover, the unique application of heat and pressure in the transfer process ensures that colors adhere remarkably well to different textile surfaces. This adaptability has propelled DTF printing to the forefront, especially for custom apparel businesses aiming to deliver high-quality products that meet the diverse demands of their clientele.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, involve a printing process where designs are printed onto a specialized film. After printing, heat and pressure are applied to transfer the design onto garments, creating vibrant, durable prints that maintain high-quality standards.

How important is size selection in DTF Transfers?

Size selection is crucial in DTF Transfers as it directly affects clarity and detail. Choosing the right size ensures that intricate designs remain visible and appealing; too small may lose details, while too large can cause adherence issues.

What is the impact of DTF printing quality on the final product?

The quality of DTF printing is vital for the final product’s appearance and durability. Using high-quality films and ensuring high-resolution images during the printing process leads to sharper, more vibrant prints, enhancing overall print quality.

What DTF transfer techniques can improve print quality?

To improve DTF transfer quality, utilize high-resolution images and properly pre-treat fabrics. Matching the design size to the garment’s print area also enhances clarity, ensuring that details are maintained during the transfer process.

What trends are currently shaping DTF printing quality?

Current trends in DTF printing focus on eco-friendly practices, such as using water-based inks, and advancements in digital size evaluation software. These innovations enhance print quality, reduce waste, and improve customer satisfaction.

How can I learn effective DTF transfer techniques?

Engaging with the DTF printing community through online forums and social media groups is an excellent way to learn effective transfer techniques. Additionally, reviewing case studies and experiences can provide valuable insights into successful practices and size selections.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | DTF involves printing designs onto a special film, which are then transferred onto garments using heat and pressure, impacting quality significantly. |

| Importance of Size Selection | Correct sizing is crucial for clarity; designs too small lose detail and those too large may not adhere properly. |

| Sizing Best Practices | Design sizes should consider print area dimensions and garment type to ensure visibility of details. |

| Quality Improvement Techniques | Using high-resolution images (minimum 300 DPI) and pre-treating fabrics improve adhesion and print quality. |

| Current Trends | Shifts towards eco-friendly inks and digital size evaluation are enhancing DTF printing quality. |

| Community Best Practices | Networking and learning from case studies within the printing community provide invaluable insights for effective DTF techniques. |

Summary

DTF Transfers have quickly become a pivotal method in the custom printing industry, offering vibrant and high-quality results. Understanding the nuances of DTF transfers, especially regarding size selection, is essential for maximizing print quality. By focusing on proper sizing, high-resolution images, pre-treatment techniques, and remaining attuned to industry trends, businesses can significantly elevate their DTF printing outputs. As innovations continue, staying connected with community best practices and embracing new technologies will further ensure success in producing quality DTF transfers.