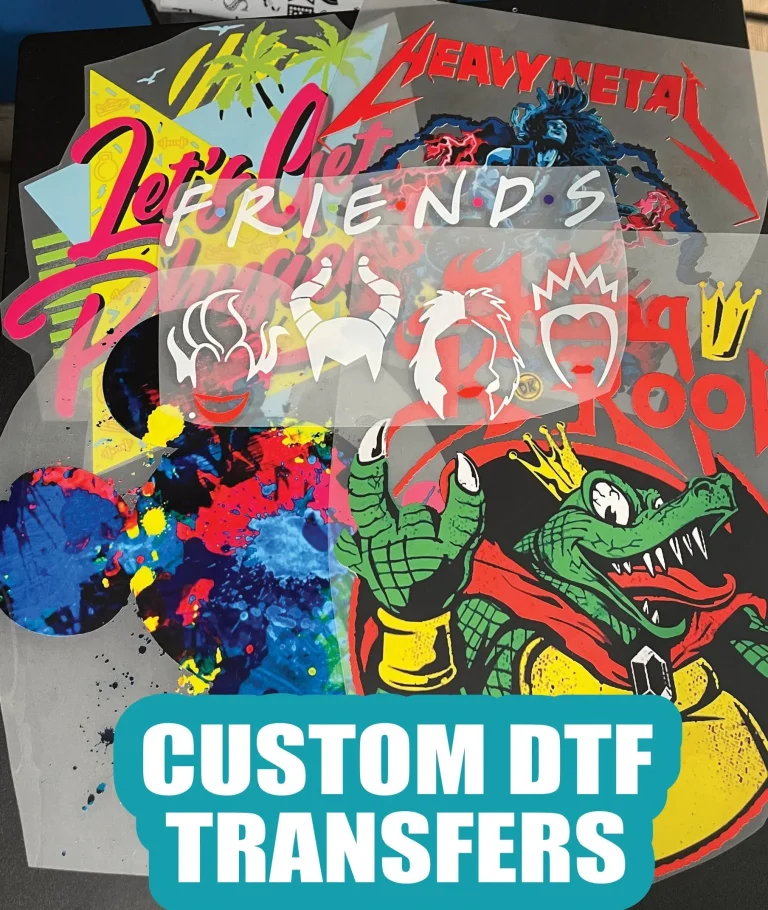

DTF transfers, or direct-to-film transfers, are emerging as a transformative force in the custom apparel industry, appealing to businesses seeking quality and efficiency. This innovative printing method leverages advanced DTF technology to produce vibrant, intricate designs that stand out on various fabrics. Unlike traditional printing methods, DTF printing benefits from a simplified process that allows for quick turnaround times and lower costs, making it an ideal choice for both small startups and established brands. Moreover, its compatibility with sustainable printing practices positions DTF transfers as a forward-thinking solution within the eco-conscious marketplace. As the demand for customizable apparel escalates, these versatile transfers are undoubtedly reshaping the landscape of apparel printing innovations.

The realm of direct-to-film printing has ushered in a new era for garment decoration, offering a fresh approach to custom apparel solutions. Known for its user-friendly nature, this technique allows for high-quality prints that enhance the visual appeal of clothing. This method, often recognized for its sustainable practices, provides a reliable alternative to traditional fabric printing, favoring lower resource consumption and waste. As businesses explore various printing options, the benefits of DTF technology and its capacity to produce exceptional results on diverse materials cannot be overlooked. Ultimately, this printing innovation aligns seamlessly with the growing trend of personalized fashion, meeting modern consumer demands with style and sustainability.

The Rise of DTF Printing in Custom Apparel

In recent years, Direct-to-Film (DTF) printing has emerged as a game-changer in the realm of custom apparel. Unlike traditional methods like screen printing, DTF transfers utilize advanced technology that allows for intricate designs and vibrant colors, even on dark fabrics. This unique capability positions DTF as a top choice for businesses looking to produce high-quality products that meet the demands of fashion-forward consumers.

The growing popularity of DTF printing can be attributed to its superior output quality and enhanced flexibility. As brands continue to seek innovative solutions to distinguish themselves, the ability to produce detailed prints on a variety of materials offers a distinct advantage in the competitive apparel market. This is further supported by a substantial increase in small businesses adopting DTF methods, eager to tap into the customizable apparel landscape.

Key Advantages of DTF Technology

DTF technology boasts several key benefits that enhance its appeal to businesses and consumers alike. Primarily, the exceptional quality of prints generated through DTF processes ensures that designs are not only vibrant but also retain their integrity through multiple washes. This durability, coupled with the ease of applying DTF transfers, makes it an attractive option for custom apparel manufacturing.

Additionally, the versatility of DTF printing cannot be overstated. Businesses can cater to a wide array of fabric types, including cotton, polyester, and blends. This adaptability not only satisfies diverse customer demands but also encourages product innovation, allowing brands to take risks in their design and offerings, thereby improving their market positioning.

Exploring the Cost-Effectiveness of DTF Transfers

One of the most compelling reasons for shifting to DTF transfers is the cost-effectiveness that they bring to the table. Unlike traditional screen printing, which can involve high setup costs and extended production timelines, DTF printing simplifies the process. It minimizes waste and lowers operational costs, enabling businesses to produce smaller runs or custom orders without breaking the bank.

This economic advantage is particularly beneficial for startups and small businesses looking to make a mark in the custom apparel landscape. The flexibility to adapt to on-demand production allows these companies not only to reduce inventory costs but also to respond quickly to customer preferences, fostering a more dynamic approach to apparel production.

Sustainability in Apparel Printing with DTF Technology

As sustainability becomes an essential criterion for consumers, DTF technology emerges as a more eco-conscious alternative to traditional printing methods. By using less water and generating fewer emissions and waste products, DTF printing aligns seamlessly with the growing demand for environmentally friendly practices in the fashion industry. This not only appeals to the environmentally conscious consumer base but also positions businesses as responsible players in the market.

Furthermore, integrating sustainability into your business model through DTF technology can enhance your brand’s reputation. As consumers increasingly gravitate towards brands that prioritize eco-friendly practices, businesses utilizing DTF printing can effectively market their commitment to sustainability while still delivering high-quality custom apparel.

Technological Innovations Driving DTF Transfers

Technological advancements in DTF printing continue to shape its trajectory and performance capabilities. Recent innovations in DTF inks and the development of high-speed printers have significantly boosted the efficiency and color precision of DTF transfers. These enhancements cater to the growing demand for complex designs and allow businesses to meet high-volume production needs without compromising quality.

These ongoing developments not only streamline the printing process but also expand the range of applications for DTF technology across various business sizes. From hobbyists launching custom apparel lines to established brands looking to refresh their offerings, the ability to adapt quickly to technological changes ensures that DTF remains a prominent player in the industry.

Future Trends in DTF Printing and Custom Apparel

The future of DTF printing in the custom apparel market appears bright, as experts anticipate a substantial increase in its adoption. This growth is fueled by an ongoing trend towards personalization and unique fashion statements among consumers, particularly in the post-pandemic landscape. The increasing preference for customized products indicates a clear avenue for DTF technology to flourish, further embedding itself into mainstream apparel production.

As more fashion entrepreneurs recognize the exceptional benefits of DTF transfers, we can expect to see a marked shift in how custom apparel businesses operate. Embracing DTF technology not only allows them to respond to consumer demands rapidly but also positions them to stay competitive amidst evolving industry standards and consumer expectations.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a cutting-edge printing method used in custom apparel that involves printing designs onto a special film, which is then transferred onto fabric. This technique allows for vibrant colors and intricate details, making DTF technology a preferred choice for high-quality apparel printing.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers several benefits for custom apparel, including superior print quality, the ability to print on various materials, cost-effectiveness for small orders, and ease of use, making it accessible for small businesses and startups.

How does DTF transfer technology compare to traditional printing methods?

Compared to traditional methods like screen printing, DTF transfer technology provides higher resolution prints, especially on dark fabrics, requires less setup time, and facilitates on-demand production, making it more efficient and versatile for custom apparel.

Are DTF transfers environmentally sustainable?

Yes, DTF transfers are considered a more sustainable printing option as they use less water and produce less waste than traditional printing methods. This aligns with the growing consumer demand for eco-friendly practices in the fashion industry.

What types of materials can DTF transfers be applied to?

DTF transfers can be applied to a wide range of materials including cotton, polyester, blends, and even leather. This versatility allows businesses to offer diverse custom apparel options to meet varying customer preferences.

How is the demand for DTF printing expected to grow in the future?

The demand for DTF printing is projected to grow significantly due to its advantages in quality, cost, and sustainability. As more businesses recognize these benefits, the trend towards personalized and unique apparel options is expected to drive further adoption of DTF technology in the custom apparel market.

| Key Benefit | Description |

|---|---|

| Superior Quality and Detail | Remarkable quality with vibrant colors and intricate designs; effective on dark fabrics. |

| Versatility | Applicable to various materials (cotton, polyester, leather) for a broad product range. |

| Ease of Use | Less setup needed compared to traditional methods, making it accessible for small businesses. |

| Cost-Effective | Lower setup costs and on-demand production for customization with better profit margins. |

| Sustainability | Uses less water and produces less waste, aligning with eco-friendly trends. |

Summary

DTF transfers are revolutionizing the custom apparel industry with their superior quality, versatility, and sustainability. As a cost-effective printing solution, they simplify production for businesses and meet consumer demand for unique, personalized clothing. The rise of DTF technology not only enhances market competitiveness but also aligns with modern consumers’ preferences for eco-friendly options. Companies embracing DTF transfers will benefit from a growing market trend toward customized fashion that emphasizes quality and individuality.