DTF Transfers, or Direct-to-Film transfers, are revolutionizing the realm of custom apparel printing, offering an innovative solution for anyone eager to personalize their clothing. This advanced method allows for intricate designs to be printed onto a special film, which is then heat transferred onto various fabrics, resulting in vibrant and durable custom clothing. As businesses and individuals alike seek high-quality apparel, the advantages of DTF become increasingly evident, including their cost-effectiveness and ease of application. Furthermore, DTF printing benefits include the ability to adapt to a wide range of materials, making it a versatile choice for designers. With its growing popularity, understanding the full potential of DTF transfers is essential for anyone looking to create standout custom apparel.

The world of custom clothing printing is being enhanced by a remarkable technology known as Direct-to-Film (DTF) printing. This method simplifies the process of producing personalized garments, catering to various fabric types while ensuring high-quality imagery and lasting durability. By harnessing the capabilities of modern printing techniques, DTF transfers empower both creators and brands to explore the full spectrum of design possibilities. With advantages like cost-efficient production and eco-friendliness, this printing technique positions itself as a favorable alternative to traditional options. As the landscape of custom apparel evolves, embracing DTF can significantly enhance the consumer experience while delivering superior results.

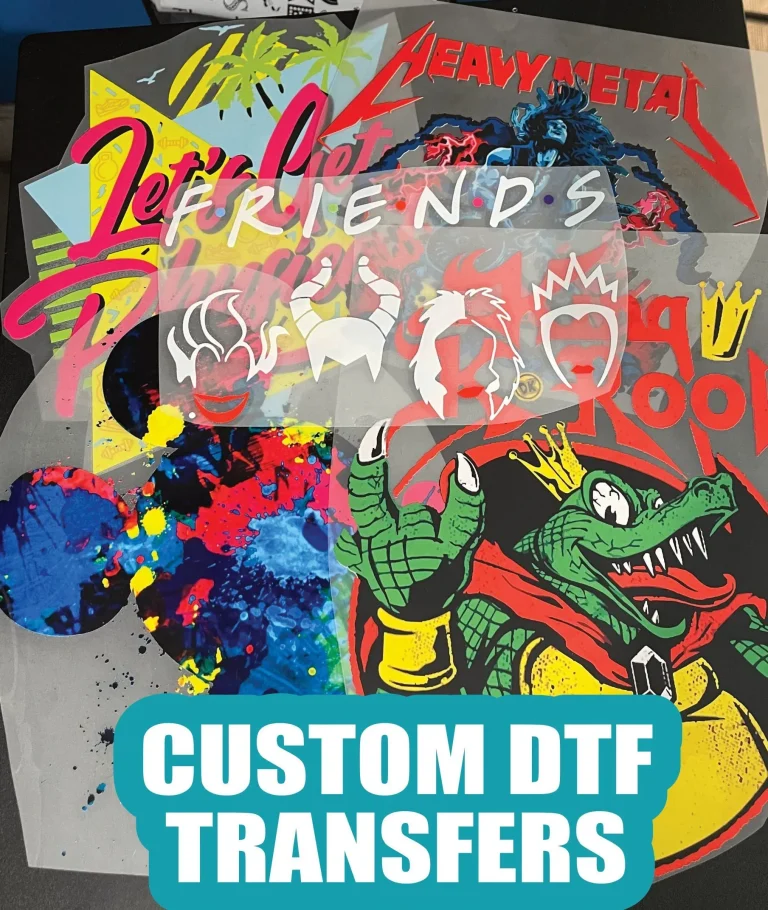

Understanding DTF Transfers: A Revolution in Custom Apparel

Direct-to-Film (DTF) transfers are quickly redefining the landscape of custom apparel printing. By leveraging advanced technology, DTF has become a favorite among designers and brand owners who wish to create detailed and vibrant designs on various textiles. This method allows ink to be printed onto a special film, which is then transferred onto the garment using heat. The intricate process not only ensures that the colors are vivid and true to life but also allows for the reproduction of high-quality images that maintain their integrity wash after wash.

Moreover, DTF transfers stand out due to their adaptability in production settings. From t-shirts and hoodies to complex fashion items, DTF caters to a wide variety of fabrics and styles, including cotton, polyester, and blends. Unlike traditional methods that can be restrictive in terms of material compatibility, DTF offers unmatched versatility, making it an ideal choice for brands that seek creative expression through custom clothing printing.

The Surging Popularity of DTF Printing Benefits

As businesses and consumers alike become more discerning about their apparel choices, DTF printing benefits have catapulted this method to the forefront of custom design. The ability to print high-quality, intricate designs means that the end product reflects superior craftsmanship. With DTF, graphics remain sharp and vibrant, even after multiple wash cycles, which is a critical factor for satisfaction among customers.

Additionally, the technology behind DTF printing has evolved. Enhanced ink formulations and transfer film options mean that consumers can enjoy a wider range of textures and finishes. Whether it’s a soft touch or a glossy sheen, the ability to customize is further enhanced, ensuring that garments can stand out in today’s competitive market. Brands investing in DTF technology can therefore offer unique clothing that meets rising aesthetic expectations.

The Durability Factor in DTF Transfers

Durability is a key concern in the custom apparel market, and this is where DTF takes center stage. DTF transfers offer resistance to cracking, fading, and peeling, ensuring that designs maintain their integrity over time. This long-lasting quality is especially beneficial for businesses aiming for sustainable customer relationships, as customers are more likely to return for additional purchases when satisfied with durable products.

Furthermore, the longevity of DTF transfers translates into cost savings for businesses. By reducing the need for frequent reprints due to wear and tear, companies can focus resources elsewhere, enhancing overall operational efficiency. This not only boosts profit margins but also rounds out the value proposition for those considering DTF technology in their printing arsenal.

Cost-Effectiveness of DTF Transfers for Small Runs

One of the standout advantages of DTF transfers is their affordability for small production runs. Unlike traditional screen printing, which often involves hefty setup costs for equipment and bulk materials, DTF allows entrepreneurs and small businesses to start with limited financial investment. This flexibility caters to a growing trend of customization in the market, where small batches featuring personalized designs can be produced without the economic pressures of large-scale manufacturing.

In addition, the capability to produce on-demand reduces waste significantly. With DTF, businesses can create garments as needed, ensuring that they can respond quickly to market trends without overcommitting to large inventory stocks. This responsiveness is crucial in a fast-paced industry, positioning DTF as a pivotal solution for brands seeking to remain agile.

Simplifying the Custom Apparel Application Process

The simplified application process of DTF transfers is transforming the way businesses approach custom apparel printing. Requiring only a heat press machine, the DTF method democratizes the printing experience, allowing even new startups or small creative teams to venture into the world of personalized clothing without significant investment in complex equipment.

Moreover, the straightforward nature of the process means less training is required for staff, which can be a major hurdle for businesses looking to swiftly implement new printing methods. Employees can quickly learn to apply the transfers, resulting in faster turnaround times and a more efficient production workflow overall.

Environmental Considerations of DTF Technology

As sustainability becomes a critical factor in consumer choices, DTF printing technology aligns with eco-conscious values. The use of water-based inks in DTF processes significantly reduces the environmental footprint compared to traditional printing methods. This shift not only attracts environmentally aware consumers but also allows companies to highlight their commitment to sustainability, reinforcing brand loyalty and encouraging repurchases.

The advantages of eco-friendly practices are amplified when businesses highlight their dedication to supporting sustainable production methods. By adopting DTF technology, brands not only enhance their market appeal to green consumers but also position themselves as leaders in the evolving landscape of responsible manufacturing practices.

Frequently Asked Questions

What are the advantages of DTF transfers in custom apparel printing?

DTF transfers offer several advantages for custom apparel printing, including compatibility with diverse fabric types like cotton and polyester, high-quality imagery with vibrant colors, and exceptional durability against wear and tear. These benefits make DTF a preferred choice for brands looking to create high-quality, personalized garments.

How does DTF printing differ from traditional custom clothing printing methods?

DTF printing differs from traditional methods such as screen printing mainly in its process and flexibility. Unlike screen printing, which requires costly setups for each design, DTF transfers can be produced quickly and cost-effectively, especially for small batches. This makes DTF ideal for businesses and individuals seeking customization without the financial burden.

What makes DTF transfers eco-friendly compared to other printing techniques?

DTF transfers are considered more eco-friendly due to the use of water-based inks, which significantly reduce environmental impact. This sustainability aspect appeals to consumers looking for eco-conscious custom apparel options, making DTF a responsible choice in the fashion industry.

Can DTF technology accommodate tailored sizing options for custom apparel?

Yes, DTF technology allows for tailored sizing options in transfers, enabling designs to be adjusted to fit specific garment dimensions. This capability ensures that custom apparel not only looks great but also provides a better fit, aligning with customer preferences for personalized clothing.

What are the key benefits of using DTF transfers for small production runs in custom clothing?

DTF transfers are cost-effective for small production runs as they do not require the high setup costs associated with screen printing. This flexibility allows businesses to create customized garments in smaller quantities without overspending, catering to niche markets and individual customer demands.

How can I get started with DTF printing for custom apparel?

Getting started with DTF printing for custom apparel is straightforward. You will need a heat press machine and access to quality DTF transfer materials. Many suppliers offer starter kits that include everything needed to start producing beautiful custom clothing, making this process accessible for small businesses and DIY enthusiasts.

| Key Point | Details |

|---|---|

| Versatility Across Fabric Types | Compatible with cotton, polyester, and blends, making it suitable for a variety of custom apparel. |

| High-Quality Imagery | Preserves intricate details and reproduces complex designs with clarity and vibrancy. |

| Durability to Last | Resistant to cracking, fading, and peeling even after many washes. |

| Cost-Effective for Small Production Runs | Allows for flexible production without high setup costs, making it ideal for small batches. |

| Simplified Application Process | Requires only a heat press machine, making it accessible for small businesses and DIY projects. |

| Environmentally Friendly Options | Uses water-based inks, reducing environmental impact and appealing to eco-conscious consumers. |

| Tailored Sizing Options | Offers custom sizing for designs ensuring a better fit on apparel. |

Summary

DTF Transfers are revolutionizing the world of custom apparel printing with their unique combination of versatility, durability, and high-quality imagery. This innovative technique utilizes a process where designs are printed on a special film and then transferred onto various fabrics, allowing for stunning visual outcomes that are resistant to wear and tear. As demand for customization grows, DTF Transfers provide an environmentally friendly and cost-effective solution for both businesses and hobbyists, ensuring that high-quality custom garments are accessible to everyone. With ongoing advancements in technology, the benefits of DTF transfers continue to redefine the standards of personalized clothing, securing their place as a vital tool in the apparel industry.