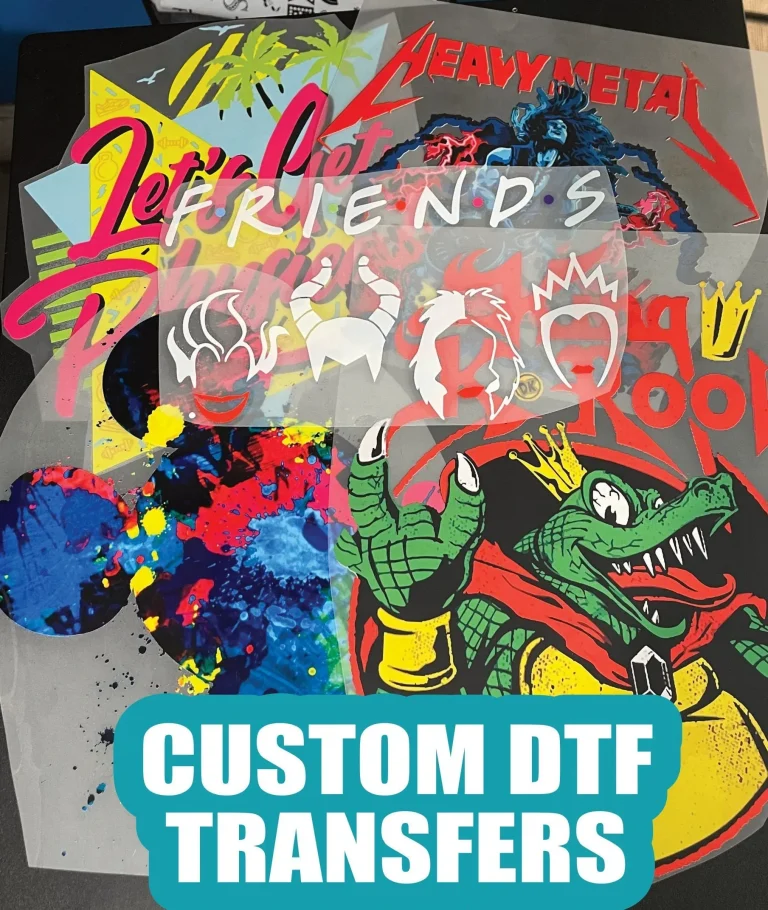

DTF transfers, short for Direct-to-Film printing, have emerged as a revolutionary solution in the textile printing arena. This innovative technique focuses on transferring intricate designs onto various fabrics using a specialized film, ensuring high-quality and vibrant results. The DTF printing benefits are plentiful, including its versatility across different materials and ease of use, appealing to both artists and small businesses. With the growing demand for eco-friendly printing practices, DTF transfers utilize sustainable inks and methods, allowing creatives to produce stunning prints while minimizing their environmental impact. As we explore the world of DTF transfer applications, you’ll discover how this technique can help you unleash your artistic potential and elevate your fabric projects to new heights.

When discussing modern fabric printing options, Direct-to-Film methods stand out as a popular choice among creators. This alternative printing process enhances design capabilities and offers a wide array of applications for apparel and accessories. With significant advancements in textile printing techniques, these digital processes provide an incredible synergy of creativity and practicality. Furthermore, the benefits of DTF printing extend beyond aesthetic appeal; they also cater to the growing demand for sustainability within the industry. As we delve deeper into the nuances of this technology, the impact of these innovative printing solutions on artists and businesses will become evident.

Understanding the Essence of DTF Transfers

Direct-to-Film (DTF) transfers represent a transformative approach to textile printing, characterized by its precision and adaptability to various materials. Unlike traditional methods, DTF printing utilizes a special film as a medium, allowing designs to be intricately printed with high fidelity before being applied to the fabric. This process not only results in vibrant colors but also provides a smoother finish, giving fabric artworks a professional quality that attracts customers looking for premium products.

Moreover, DTF transfers are not restricted to a single type of fabric. Artists and businesses can print on cotton, polyester, and blends, which expands the scope of creative possibilities. This versatility ensures that DTF printing can cater to diverse markets, from fashion to promotional items, making it an attractive option for entrepreneurs aiming to differentiate their products in a crowded marketplace.

Key Benefits of DTF Printing Techniques

DTF printing techniques offer several benefits that set them apart from other textile printing methods, primarily in terms of durability and color blending. The prints created using DTF transfers exhibit exceptional resistance to fading and wear, making them ideal for items like T-shirts that undergo frequent washing. This durability not only ensures customer satisfaction but also reinforces brand loyalty as consumers seek long-lasting products.

Additionally, DTF transfers allow for intricate color blending and gradients, enabling artists to create visually stunning designs that captivate audiences. Artists can experiment with complex color schemes without worrying significantly about the limitations often associated with screen printing or other rigid methods. This flexibility promotes greater creativity, empowering artists to push the boundaries of their craft.

Recent Trends in DTF Transfer Innovations

The DTF transfer landscape is rapidly evolving, with recent trends highlighting increased accessibility and sustainability within the industry. Affordable DTF printers from reputable brands like Epson and Mimaki are flooding the market, making high-quality printing techniques available to smaller businesses and independent creators. This democratization of technology fosters growth in the textile printing sector, inspiring a new wave of entrepreneurship focused on creativity.

Furthermore, the movement towards eco-friendly printing solutions has also become prominent in DTF technology. Innovations in water-based inks and recyclable transfer films have emerged, significantly lowering environmental impact. As consumers become more conscientious about sustainability, eco-friendly options in DTF printing not only meet this demand but also enhance brand appeal, providing a competitive edge in the marketplace.

Challenges Facing DTF Transfers

Despite the numerous advantages of DTF transfers, artists and businesses encounter challenges that can impact their experience with this printing method. Initial setup costs can still be substantial; while the overall investment is lower compared to traditional printing methods, high-quality DTF printers and materials come with a price tag that can deter newcomers. Proper budgeting and financial planning become essential for those looking to dive into DTF printing.

Additionally, the learning curve associated with DTF transfers can pose a meaningful challenge. Artists must familiarize themselves with specific heat settings, transfer processes, and maintenance of the equipment to achieve optimal results. This learning phase may initially slow down production but ultimately enhances skill sets and can lead to professional growth in textile printing.

Exploring the Applications of DTF Transfers

The versatility of DTF transfers allows them to be applied in various fields, from fashion to merchandising and promotional items. Their ability to easily adhere to different types of fabric makes them a perfect choice for creating customized T-shirts, bags, and other textile products that appeal to a wide range of audiences. Businesses can effectively tap into niche markets by providing unique and personalized items, ultimately driving sales and expanding their customer base.

Moreover, DTF transfers have also found applications in creating intricate designs for home decor, enabling artists to express their creativity beyond apparel. From decorative cushion covers to stunning wall hangings, the potential applications are virtually limitless. This adaptability not only showcases the creative talents of artists but also offers exciting opportunities for diversification in product offerings.

The Future Outlook for DTF Printing

As technology continues to advance, the future of DTF printing looks promising with numerous opportunities for growth and innovation. Ongoing research into better materials and processes is likely to yield even more remarkable results, enhancing the quality and sustainability of DTF transfers. This continuous evolution positions DTF printing as a key player in the textile industry, equipped to handle the ever-changing market demands and consumer preferences.

Moreover, as more artists and businesses embrace DTF printing, the community and sharing of best practices will flourish. This collaboration will foster a spirit of continuous improvement and innovation, allowing the industry to respond proactively to emerging trends. Those who adopt DTF technology early may find themselves at the forefront of artistic expression in the textile sector, giving them a distinct competitive edge.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, utilize a unique film that prints designs for transfer onto fabrics. The printing process involves transferring the artwork onto a special film, which is then applied to the fabric using heat and pressure. This technique provides versatility across various materials, making it ideal for textile printing projects.

What are the key benefits of using DTF printing?

DTF printing offers several significant benefits including versatility for different fabric types, high durability with resistance to cracking and fading, cost-effectiveness for small production runs, and the ability to create designs with complex color blending, enhancing the visual impact of your artwork.

How does DTF printing compare to other textile printing techniques?

Compared to other textile printing techniques like Direct-to-Garment (DTG), DTF printing is more versatile as it works well on various fabrics including cotton and polyester. Additionally, DTF transfers produce vibrant colors and maintain high durability, making them a preferred choice for many artists and businesses.

Can DTF transfers be considered eco-friendly printing?

Yes, many DTF transfers now utilize water-based inks and recyclable films, which contribute to more sustainable practices in textile printing. As eco-consciousness grows, DTF printing is evolving to reduce its environmental footprint, making it a more eco-friendly option for artists and businesses.

What types of applications are suitable for DTF transfers?

DTF transfers are suitable for a wide range of applications, including T-shirts, bags, and various textile products. Their adaptability allows artists to explore different projects, ensuring that complex designs with intricate color blends can be effectively realized on different fabrics.

What challenges might I face when starting with DTF printing?

Challenges in DTF printing include potential initial setup costs for quality printers and supplies, as well as a learning curve associated with mastering the heat settings and transfer process. However, overcoming these hurdles can significantly enhance your artistic skills and output in the fabric printing industry.

| Key Points | Description |

|---|---|

| What is DTF Printing? | A technique using a unique film to transfer designs onto fabric, known for its versatility and vibrant color reproduction. |

| Benefits of DTF Transfers | Includes versatility across various fabrics, high durability, cost-effectiveness, and easy color blending capabilities. |

| Recent Trends and Innovations | Emerging trends include increasing accessibility, environmental considerations, and user-friendly applications for artists. |

| Challenges and Limitations | Challenges include initial setup costs and a learning curve for mastering techniques, requiring time and practice. |

| Conclusion | Embracing DTF transfers enhances creativity in textile arts, with technology improvements paving the way for future innovation. |

Summary

DTF transfers are a groundbreaking approach in textile printing that combines innovation with artistry. This technique empowers artists and businesses to produce outstanding designs that cater to a wide range of fabric types, making it an invaluable tool in the world of fabric arts. With added benefits such as durability, cost-effectiveness, and the ability to create intricate designs, it’s clear that DTF transfers are not just a temporary trend, but a significant leap forward for both individual creators and commercial enterprises. As technology continues to evolve and offer new solutions, the possibilities for artistic expression through DTF transfers will only expand, ensuring that this method remains at the forefront of printing techniques.