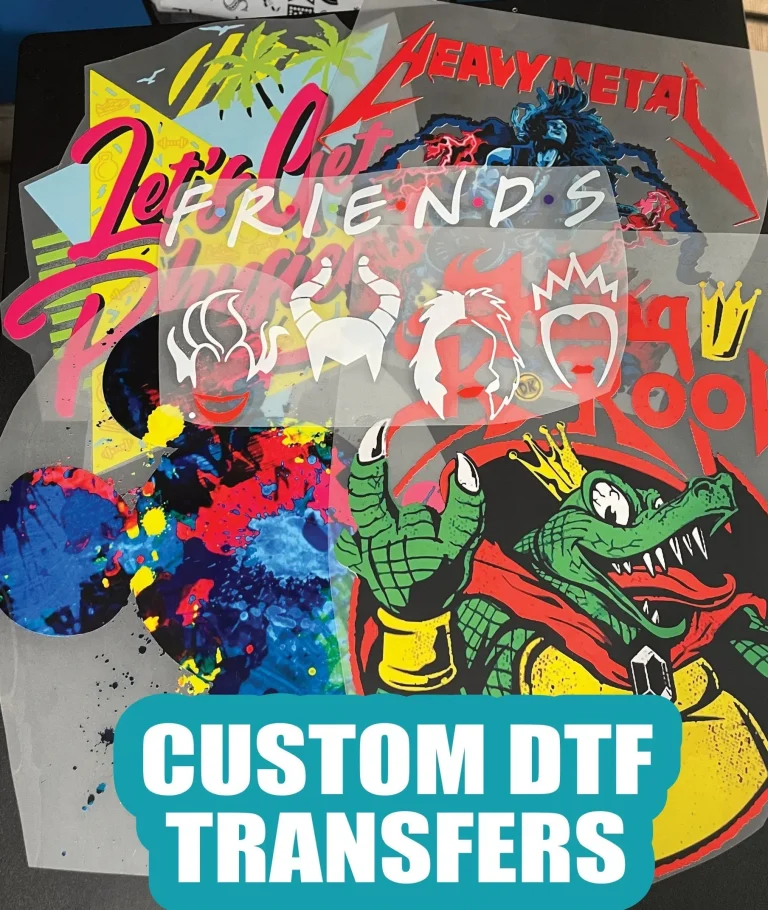

In the fast-evolving landscape of custom apparel, **DTF transfers** are emerging as a game-changing force in printing technology. This innovative method, known as Direct to Film printing, allows businesses to create vibrant, eye-catching designs that resonate with today’s fashion trends. With its ability to deliver high-quality prints and exceptional durability, DTF transfers are not just a fleeting innovation but a cornerstone for entrepreneurs aiming to thrive in a competitive market. This article will guide you through effective business tips to harness the potential of DTF printing, transforming your custom apparel offerings. As consumers increasingly seek personalized and unique garments, embracing DTF transfers could be the key to maximizing your business success.

When exploring options for custom clothing production, many print shop owners may come across terms like Direct to Film technology or specialized film transfers. These cutting-edge printing methods are designed to streamline the process of customizing apparel while maintaining a strong emphasis on detail and color vibrancy. By utilizing film printing techniques, businesses can cater to diverse customer needs, from bold graphics to subtle designs. This approach not only meets the rising demand for personalized garments but also keeps pace with emerging fashion trends. Understanding these alternative methods can provide valuable insights for optimizing your custom apparel production strategy.

Understanding the Mechanics of DTF Printing

Direct to Film (DTF) printing is a groundbreaking technology in the custom apparel industry, transforming how designs are applied to fabrics. At its core, this process involves printing a design onto a special film, which is then transferred to clothing using heat and pressure. This unique method allows for exceptional detail and vivid color reproduction, catering to the needs of modern consumers who demand individuality and high-quality products. As the market for personalized apparel continues to rise, understanding these mechanics can empower businesses to leverage DTF printing to meet consumer demands effectively.

Moreover, the technical aspect of DTF transfers involves the use of specialized inks that are engineered to adhere well to various fabric types, from cotton to more intricate blends. This opens up numerous avenues for creativity, as businesses can experiment with unique materials and designs without compromising on quality. The seamless integration of DTF technology within existing production lines can also streamline workflow, enhancing overall operational efficiency. With the right approach, businesses can fully exploit the advantages offered by DTF printing to establish a strong foothold in the competitive landscape of custom apparel.

Exploring the Remarkable Benefits of DTF Transfers

DTF transfers present a range of impressive benefits that can significantly impact a business’s bottom line. One of the primary advantages is cost-effectiveness. Unlike traditional printing methods that often require large minimum orders, DTF allows small businesses and startups to produce high-quality prints with lower initial investment. This means entrepreneurs can test new designs and collections without the financial risk associated with bulk production, opening new doors for creativity and innovation in the custom apparel market.

In addition to being budget-friendly, DTF transfers excel in color vibrancy and durability, producing eye-catching designs that draw customer attention. The technology allows for stunning prints that resist fading and cracking over time, which can enhance customer satisfaction and loyalty. By offering high-quality products that stand the test of time, businesses can build a reputation for excellence, leading to repeat customers and positive word-of-mouth marketing. These benefits collectively establish DTF transfers as a vital element for those looking to thrive in the dynamic landscape of custom apparel.

Essential Tips for Effective DTF Transfer Implementation

To harness the full potential of DTF transfers, investing in quality equipment is crucial. A top-tier printer that supports DTF technology is essential for producing vibrant, detailed prints. Additionally, a reliable heat press will ensure that transfers are applied correctly and consistently. Businesses should prioritize researching reputable brands known for their performance in DTF printing. By making a sound investment in quality machinery, businesses set the foundation for creating exceptional products that meet their customer’s expectations.

Another significant tip is to master design techniques that resonate with your target audience. Utilizing advanced graphic design software, entrepreneurs can craft stunning visuals that reflect current fashion trends and consumer desires. Training in effective DTF design practices will not only differentiate your offerings but also elevate your brand image. By developing designs that are both unique and appealing, businesses can carve out their niche, attracting a dedicated customer base eager for custom apparel.

Navigating Market Demands for Successful DTF Apparel

Understanding your market plays a pivotal role in the success of any custom apparel business, especially when utilizing DTF transfers. Businesses must engage in thorough market analysis to determine what products and designs resonate with their audience. Whether it’s event-themed apparel or corporate branding, tailoring offerings to meet specific demands can lead to increased sales. By staying attuned to consumer behavior and preferences, businesses can position themselves advantageously within the competitive landscape, capturing market share and driving growth.

Furthermore, responding to emerging consumer trends, such as eco-friendliness and personalization, can set businesses apart. DTF technology allows for rapid customization, enabling companies to cater to the growing demand for unique, personalized items. By embracing these trends and adapting their product lines accordingly, businesses can not only satisfy customer needs but also proactively assert their presence in an evolving market. This strategic alignment with consumer demands can foster brand loyalty and stimulate continual enterprise success.

Key Trends Shaping the Future of DTF Printing

The custom apparel market is dynamic, and staying informed about emerging trends can be a game-changer for businesses leveraging DTF transfers. Personalization is currently at the forefront, with consumers increasingly seeking unique items that reflect their individual tastes. DTF printing technology allows businesses to efficiently create bespoke pieces, from custom graphics to personalized messages, enabling them to meet and exceed customer expectations. Companies that embrace these personalization trends will likely benefit from enhanced customer engagement and increased sales.

Additionally, fashion sustainability has gained momentum, pushing the industry towards more environmentally friendly practices. DTF printing, when executed correctly, can use eco-conscious inks and materials that appeal to today’s environmentally aware consumers. Businesses adopting sustainable practices while utilizing DTF technology not only contribute positively to the environment but also attract a conscientious customer base, reinforcing their brand’s reputation in the marketplace. Keeping abreast of these trends will help businesses remain relevant and competitive in the ever-evolving apparel sector.

Common Challenges in DTF Printing and How to Overcome Them

While the advantages of DTF printing are significant, business owners must also contend with challenges that can arise in the production process. A notable barrier is the learning curve associated with mastering this technology. Without proper knowledge and training, even the best equipment can yield subpar results. Therefore, investing time in comprehensive training for staff, and familiarizing them with troubleshooting common issues can be pivotal in ensuring smooth operations. Regular workshops and educational resources can empower teams to effectively manage the DTF printing process, thereby reducing the likelihood of costly mistakes.

Additionally, managing the inventory of transfer films can be daunting. Businesses need to keep a diverse stock of materials on hand to meet customer demands promptly. Ignoring this aspect can lead to delays in production and order fulfillment, ultimately hindering customer satisfaction. Establishing a systematic inventory management approach can help streamline operations, allowing businesses to maintain sufficient supplies of transfer films. By proactively addressing these common challenges, businesses can ensure that they fully capitalize on the benefits of DTF printing while fostering a positive customer experience.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct to Film transfers, are a modern printing method where designs are printed on a special film and then transferred to fabrics using heat and pressure. This technique allows for vivid colors and intricate details, making it ideal for custom apparel in today’s competitive market.

What are the advantages of using DTF printing for custom apparel?

The advantages of DTF printing include cost-effectiveness due to low minimum order quantities, exceptional color vibrancy, durability against cracking and fading, and versatility across various fabric types, including cotton and polyester, allowing businesses to create unique custom apparel.

How can I maximize my business potential with DTF transfers?

To maximize your business potential with DTF transfers, invest in high-quality equipment, master effective design techniques, understand your target market, and maintain a diverse inventory of transfer films. These strategies will enhance the quality of your offerings and improve customer satisfaction.

What types of materials can DTF transfers be applied to for custom apparel?

DTF transfers are versatile and can be applied to a variety of substrates including cotton, polyester, and blends. This flexibility allows businesses to cater to different customer preferences for custom apparel.

What are some emerging fashion trends related to DTF printing?

Emerging fashion trends related to DTF printing include personalization and demand for unique apparel items. Consumers are increasingly seeking customized garments, and DTF technology is perfectly positioned to meet this demand efficiently.

What challenges should businesses consider when using DTF transfer technology?

Challenges in using DTF transfer technology include the learning curve associated with mastering the printing process and the need for proper training to avoid costly mistakes. It’s important for business owners to invest time in education and troubleshooting strategies to take full advantage of DTF printing.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF is a method where designs are printed on a special film and then transferred to fabric using heat, allowing for high detail and quality. |

| Cost-Effectiveness | Low minimum order quantities make DTF transfers accessible for small businesses and startups. |

| Color Vibrancy | DTF printing produces bold colors and sharp images, critical for attracting customers. |

| Durability | DTF prints resist cracking and fading, ensuring a longer-lasting product. |

| Versatility | Works well on cotton, polyester, and blends, allowing endless customization possibilities. |

| Invest in Quality Equipment | High-quality printers and heat presses yield better-quality prints, enhancing customer satisfaction. |

| Master Design Techniques | Use powerful graphic design software to create visually appealing graphics that resonate with the target audience. |

| Understand Your Market | Analyze the target audience to tailor products that meet specific demands, driving sales effectively. |

| Maintain Inventory of Transfer Films | Keeping a diverse inventory ensures quick turnaround times for customer orders. |

| Emerging Trends | Personalization is a growing trend that DTF transfers can efficiently cater to. |

| Challenges | There is a learning curve to using DTF technology, necessitating education and training. |

Summary

DTF transfers are a revolutionary tool for maximally harnessing the potential of your custom apparel business. By understanding the intricacies of this printing method, investing in quality equipment, and mastering design techniques, businesses can create vibrant, durable, and versatile products that meet consumer demands. Keeping up with market trends, including the demand for personalization, and addressing potential challenges through education and training are crucial for sustaining competitiveness in the evolving apparel market. Implementing these strategies can decisively expand your offerings and enhance customer loyalty, ultimately driving your business towards success.