DTF Transfers, or Direct-to-Film transfers, are revolutionizing the world of custom apparel design by allowing intricate designs to be printed onto fabric with striking clarity. This advanced printing technique not only produces vibrant colors but also offers remarkable versatility, accommodating various fabric types. As the demand for personalized clothing rises, understanding the art of DTF printing techniques becomes crucial for designers looking to stay ahead in a competitive market. The key to maximizing DTF designs lies in mastering the size of your transfers, ensuring that every detail is captured beautifully. In this guide, we’ll delve into the essential aspects of DTF transfers and explore how size impacts the effectiveness and clarity of your designs.

Exploring the realm of Direct-to-Film transfer printing provides a fascinating glimpse into the future of custom garment creation. Known for its efficiency and vivid color reproduction, this technique enables designers to transfer elaborate graphics onto fabrics seamlessly. Tailoring apparel designs requires a keen understanding of transfer dimensions, as the size can significantly enhance or detract from the visual impact of your artwork. By dissecting the nuances of DTF printing methods and the importance of optimizing design sizes, one can truly harness the potential of this innovative approach. Let’s uncover the best practices that will elevate your custom applications and ensure your creations stand out.

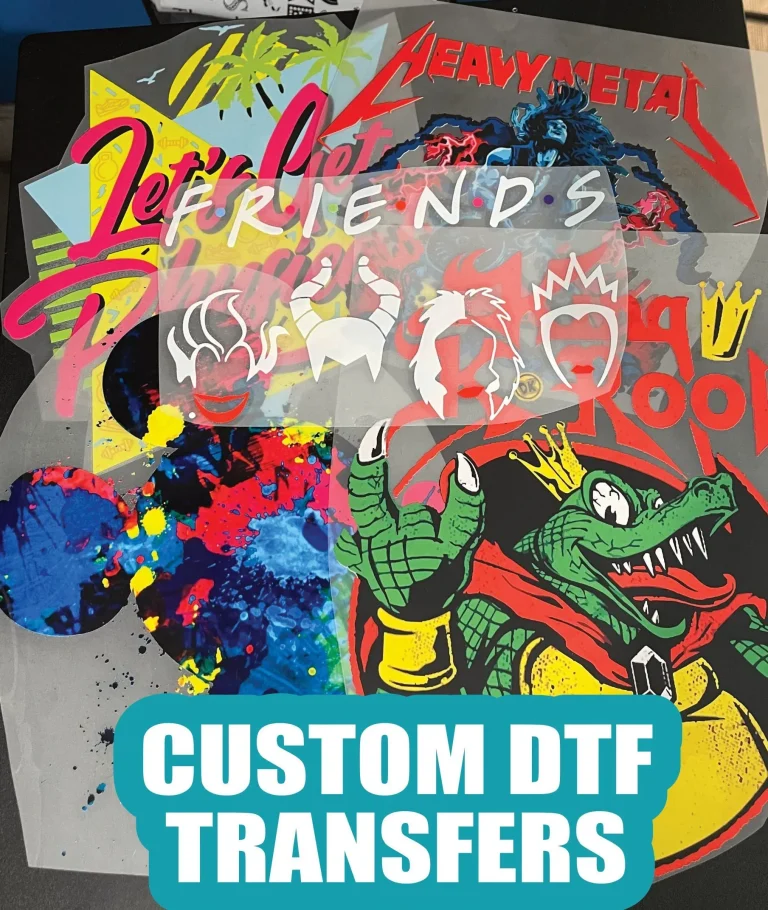

Understanding the Basics of DTF Transfers

DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry by offering a method that combines flexibility and high-quality output. This technique involves printing designs directly onto a special film using advanced digital printing equipment. Once printed, the design is adhered to the fabric using heat and pressure, resulting in a vibrant, long-lasting graphic. The beauty of DTF transfers lies in their ability to handle complex designs and a wide color palette, making them invaluable for designers looking to create standout pieces.

What makes DTF transfers particularly appealing is not just their quality but also their multi-fabric compatibility. Whether it’s cotton, polyester, or blends, DTF allows for a seamless transfer of designs, making it suitable for a diverse range of apparel. This versatility has led to an increase in demand across different sectors, from fashion to promotional items, thus positioning DTF as a staple in custom apparel printing.

The Role of Size in DTF Printing

Understanding size in DTF printing is crucial for achieving a visually striking design. The dimensions of your design can make or break its effectiveness on a garment. Larger designs tend to attract attention and work best on bigger items such as sweatshirts or t-shirts, creating an impactful statement. Conversely, smaller designs can enhance the elegance of accessories such as caps or bags, bringing sophistication and uniqueness to the final product.

When strategizing on design size, it’s important to evaluate both the target garment and the intended design outcome. Larger prints can leverage more detail and vibrancy, allowing for a bolder artistic expression. In contrast, smaller prints require a careful approach to maintain clarity and avoid overwhelming the item. Adopting a methodical approach by testing design sizes on different fabric types ensures optimum results and helps in identifying which dimensions serve best.

Best Practices for Effective DTF Transfers

To maximize the potential of your DTF transfers, adherence to best practices is essential. One of the foundational steps is ensuring your designs are of high resolution; a minimum of 300 DPI is recommended for larger prints. This ensures that even when scaled up, the details of the design remain intact, preventing issues like pixelation that can detract from the overall quality.

Moreover, pre-press preparation plays a pivotal role in the longevity and clarity of prints. Selecting the appropriate transfer paper, along with setting the printer correctly, is fundamental to achieving sharp, vivid results. Additionally, experimenting with various sizes through sample prints before mass production can illuminate the ideal design dimensions for each specific fabric, ensuring that the final product is both aesthetically pleasing and of high quality.

Emerging Trends in DTF Design Technology

The landscape of DTF design is rapidly advancing, with emerging trends shaping how designs are created and implemented. One notable trend is the use of creative layering techniques which allow designers to blend sizes, patterns, and textures, creating visually impressive effects that elevate the uniqueness of custom designs. This approach fosters the creation of multi-dimensional aesthetics that are hard to replicate using traditional methods.

In tandem with creativity, sustainability is also becoming a dominant theme. As consumer awareness around environmental impact grows, many brands are pivoting towards eco-friendly inks and materials in their DTF processes. This shift not only fulfills consumer demand for responsible production but also enhances brand image, making companies more appealing to eco-conscious shoppers. Keeping up with these trends is essential for designers aiming to stay relevant in a competitive market.

Key Considerations for DTF Transfer Customization

When customizing DTF transfers, several key considerations can significantly impact the outcome. Beyond selecting the right sizes for your designs, understanding the behavior of your selected fabric type is vital. Different materials may react differently to heat, and it’s critical to test how well they hold the DTF transfer. This ensures that the final product not only looks good but also retains quality over time.

Additionally, incorporating feedback from previous projects can help refine your approach to future designs. Analyzing the success and challenges faced in earlier transfers allows for continuous improvement in both the size and application techniques used. This iterative process contributes to mastery in customization, resulting in products that meet both consumer expectations and company standards.

Resources and Tools for DTF Transfers Mastery

For those keen on diving deeper into DTF transfers, various resources offer invaluable guidance. Websites like Printavo provide extensive articles and blogs that focus on optimizing printing techniques and strategies for size management. Through these platforms, designers can gain insights into improving their DTF printing processes and learn from industry leaders.

Another excellent resource is Bella+Canvas, which offers educational content specifically targeting DTF transfers. As you explore these tools, you will uncover more best practices, tips on design optimization, and inspiration from established professionals. Engaging with these resources can not only enhance your understanding of DTF transfers but also equip you with the knowledge to innovate and excel in custom apparel design.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed onto a special film using digital printers. After printing, these designs are transferred onto fabric through heat and pressure, resulting in high-quality, vibrant images that are long-lasting and suitable for various fabric types.

Why is the size important in DTF printing?

The size of DTF transfers greatly influences the design’s aesthetic impact. Larger designs suit bigger garments like hoodies, making bold statements, while smaller designs are ideal for delicate items like accessories. Choosing the right size ensures clarity and the desired visual effect on different products.

What is the best resolution for DTF designs?

For optimal results in DTF transfers, starting with high-resolution designs is critical. A DPI of 300 is recommended, especially for larger prints, to maintain clarity and vibrancy, preventing pixelation or blurriness during the transfer process.

How can I maximize my DTF designs through sizing?

To maximize DTF designs, evaluate garment size and design intent, ensure high resolution, choose the right transfer paper, and conduct test prints in various sizes. This approach helps in identifying the most effective size for your designs on different fabric types.

Are there any current trends in DTF printing techniques?

Yes, current trends in DTF printing include creative layering techniques for unique textures, the use of eco-friendly materials to cater to sustainability demands, and an increase in intricate designs that emphasize customization, making it essential to adapt sizing and placement.

Where can I find more resources to learn about DTF transfers?

For further learning about DTF transfers, you can visit resources like Printavo for insights on optimizing DTF printing techniques, and Bella+Canvas for practical guides on best practices in DTF transfers.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers utilize a special film for transferring vibrant designs onto fabrics via heat, offering versatility in color and detail. |

| Importance of Size | The size of the DTF transfer influences the visual impact, with larger designs suited for big garments and smaller designs ideal for detailing. |

| Choosing the Right Size | Consider the garment size and desired aesthetic; larger items can handle bigger graphics while smaller items may need minimal designs. |

| Best Practices | Ensure high-resolution designs, prepare the right transfer settings, and test various sizes before production. |

| Trends in DTF Transfers | Creative layering, eco-friendly materials, and intricate designs are reshaping the DTF landscape. |

| Resources for Learning | Sites like Printavo and Bella+Canvas offer insights and guides for optimizing DTF transfers. |

Summary

DTF Transfers are a revolutionary technique in custom apparel printing that allows for high-quality, vibrant designs to be transferred onto fabric. Understanding the key role of size in DTF printing is essential to maximizing the visual impact of your designs. By choosing the right dimensions, employing best practices for clarity and print quality, and keeping abreast of the latest trends in design and sustainability, you can significantly enhance your DTF transfer projects. Whether focusing on larger statements or detailed accents, knowing how to leverage size effectively will lead to remarkable, eye-catching results in your apparel.