DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom merchandise space by offering an innovative solution for printing vibrant designs directly onto a variety of fabrics. This cutting-edge technique involves printing designs onto a specialized film and then using heat to transfer them onto items like t-shirts and bags, providing countless options for brands looking to showcase their creativity. As we explore the pros and cons of DTF printing, it’s crucial to weigh its advantages, such as versatility and cost-effectiveness, against potential downsides like durability concerns. The DTF printing advantages make it a noteworthy choice for small businesses and independent creators wanting to make their mark in a competitive market. However, understanding the DTF printing disadvantages will help in making informed decisions in the custom merchandise industry.

Direct-to-Film (DTF) transfer printing is emerging as a popular method among those in the custom apparel sector, leveraging advanced technology to create stunning designs with remarkable ease. This approach allows for intricate artwork to be seamlessly transferred onto textiles, appealing to a broad audience that values both quality and flexibility in merchandise production. The idea of utilizing film-based transfers brings various insights into the fabric decoration world, encouraging businesses to reflect on the overall production process. By examining the effectiveness of this technique and its impact on small scale runs, manufacturers can better understand its role in shaping the future of custom merchandise. As we navigate through the landscape of DTF printing options, its unique characteristics and implications come to light, offering a comprehensive view necessary for strategic decision-making.

Understanding DTF Transfers in Custom Merchandise

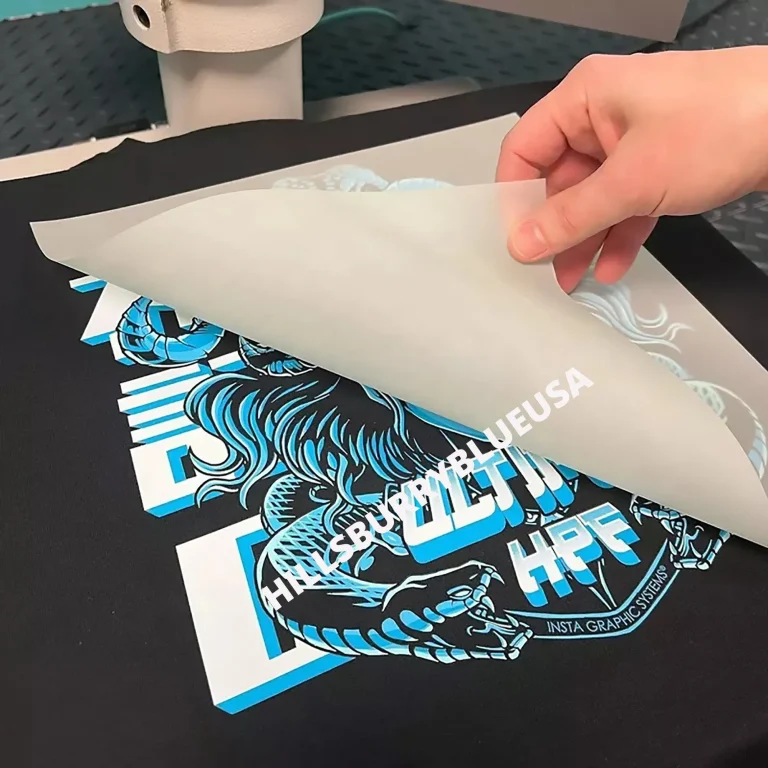

Direct-to-Film (DTF) transfers are revolutionizing the custom merchandise landscape by offering a modern printing solution that enhances design quality and versatility. Unlike traditional methods, DTF transfers involve printing images onto a special film, which is then heat-pressed onto fabric. This technique allows for the creation of intricate and vibrant designs that cater to diverse fashion needs. As businesses begin to adopt DTF transfers, they experience not only greater creativity in custom merchandise but also improved production efficiency, which is critical in today’s competitive market.

Furthermore, the DTF process supports a wide range of materials, from cotton to polyester blends, which expands the possibilities for custom merchandise applications. This flexibility allows designers to cater to various customer preferences, whether it’s for apparel like t-shirts, hoodies, or for accessories like bags. The ability to adapt to different fabrics without sacrificing quality highlights the importance of DTF transfers in capturing current fashion trends and customer demands.

The Pros and Cons of DTF Printing

DTF printing presents numerous advantages for businesses aiming to produce high-quality custom merchandise. One of the most significant benefits of this method is its cost-effectiveness, particularly for small production runs. Unlike conventional screen printing that often incurs steep setup costs, DTF allows for shorter runs without prohibitive expenses, making it an attractive option for independent creators and small business owners looking to test their designs in the market.

On the flip side, while there are substantial benefits, there are also notable drawbacks associated with DTF printing. Initial equipment costs can be a barrier for newcomers in the industry, as the necessary printers and heat press machines can require significant upfront investment. Additionally, there may be challenges related to the handling and application of DTF transfers, necessitating skilled personnel for effective execution.

The Advantages of DTF Transfer Printing

One of the standout advantages of DTF transfers is the quality of prints produced. Designs transferred using this method boast vibrant colors and exceptional detail, making them appealing to consumers. Further emphasizing quality, DTF transfers offer durability against regular wear and laundering, which is crucial for apparel businesses. Retailers are increasingly seeking printing technologies that not only look great but also last long, positioning DTF as an appealing choice in the apparel market.

Additionally, DTF printing excels in terms of turnaround time. The efficient production process allows businesses to fulfill orders rapidly, which is vital in today’s on-demand marketplace. This speed enables brands to adapt quickly to fashion trends and customer requests, ensuring they maintain a competitive edge. For entrepreneurs looking to capitalize on fast-evolving trends, DTF transfer printing serves as a reliable solution.

The Disadvantages of DTF Transfer Printing

Despite its many benefits, DTF transfer printing is not without its disadvantages. One significant concern is the potential for durability issues over time. While DTF prints are generally durable, they may not measure up to the longevity of other printing methods such as traditional screen printing. Business owners must educate themselves and their customers about appropriate care to prevent fading and peeling, as these factors could impact customer satisfaction and repeat business.

Another drawback lies in the initial costs associated with setting up a DTF printing operation. This includes not just the printer and heat press but also the cost of materials such as transfers and inks. While these costs can be offset by the efficiency and savings realized over time, they can deter budding businesses in a capital-intensive industry. Evaluating these costs versus potential profitability is crucial for any entrepreneur considering DTF printing.

How DTF Transfers Compare to Other Printing Methods

When it comes to custom merchandise, understanding how DTF transfers stack up against alternative techniques is vital for informed decision-making. For instance, unlike sublimation printing, which only works effectively on polyester fabrics, DTF transfers have a broader application range. This allows businesses to experiment with diverse materials and expand their product offerings without being constrained by fabric type.

Moreover, comparing DTF to direct-to-garment (DTG) printing reveals additional differences. While DTG printing is excellent for complex designs on cotton fabrics, DTF provides a more economical route for smaller runs. This distinction makes DTF an appealing choice for startups and small brands looking to launch collections without incurring the hefty costs associated with larger-scale printing methods.

Strategies for Successfully Implementing DTF Transfer Printing

To successfully incorporate DTF transfers into a custom merchandise production line, businesses must prioritize quality control and staff training. Ensuring that personnel are well-versed in the intricacies of the DTF printing process—from printing on the film to the heat pressing technique—can significantly enhance the end product quality. Regular workshops and hands-on training can streamline operations and reduce the risk of errors that could compromise the merchandise quality.

Furthermore, businesses should invest in high-quality materials to maximize the advantages of DTF transfers. Using premium inks and films can significantly affect the vibrancy and durability of the final product. Establishing relationships with reliable suppliers will ensure that materials meet the necessary standards, ultimately improving customer satisfaction and brand reputation in the competitive custom merchandise market.

Frequently Asked Questions

What are DTF transfers and how do they work in custom merchandise?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film before using heat and pressure to apply the design to various fabrics. This method is gaining popularity in custom merchandise due to its versatility and ability to produce high-quality prints.

What are the key advantages of using DTF printing for custom merchandise?

DTF printing offers several advantages for custom merchandise, including versatility across different fabric types, vibrant and durable prints, cost-effectiveness for small production runs, and quick turnaround times. These features make it appealing for brands looking to meet diverse consumer demands.

What are the disadvantages of DTF transfer printing for custom merchandise production?

While DTF transfer printing is innovative, it does come with disadvantages, such as high initial equipment costs, the need for precise handling during application, potential durability issues over time, and environmental concerns associated with the materials used.

How does DTF transfer compare to other printing methods in terms of quality?

DTF transfers provide high-quality prints with vibrant colors and sharp details, often surpassing methods like heat transfer vinyl. However, they may not match the durability of traditional screen printing or sublimation in the long run, which can affect customer satisfaction.

Is DTF transfer printing a sustainable option for custom merchandise?

Sustainability in DTF transfer printing is a concern due to the inks and adhesives used. Businesses prioritizing eco-friendliness need to consider the environmental impact of these materials and weigh it against the benefits of using DTF in their custom merchandise production.

Can small businesses benefit from using DTF transfers for custom merchandise?

Yes, small businesses can greatly benefit from DTF transfers due to their cost-effectiveness for short runs, versatility in fabric choices, and the ability to produce high-quality designs. This allows emerging brands to explore creative ideas without significant financial risks.

| Aspect | Pros | Cons |

|---|---|---|

| Versatility | Applicable to various fabric types (cotton, polyester) allowing diverse market reach. | Requires precise handling to ensure quality application; misalignment can lead to poor results. |

| High-Quality Prints | Produces vibrant colors and durable prints that withstand washing. | Durability may not match sublimation or traditional methods; risk of fading and peeling over time. |

| Cost-Effective for Small Runs | Lower upfront costs for small production runs compared to traditional printing. | Initial investment in equipment can be a barrier for startups and small businesses. |

| Quick Turnaround Time | Efficient production methods facilitate quick fulfillment of orders. | Requires skilled personnel for quality control during the handling and application process. |

| N/A | N/A | Environmental impact of inks and adhesives raises sustainability concerns. |

Summary

DTF transfers are revolutionizing the custom merchandise landscape by offering unique advantages like versatility, speed, and high-quality prints for small businesses. As small creators and brands embrace these benefits, they must also navigate the challenges associated with upfront costs and durability. Balancing the pros and cons of DTF transfers is vital for making sustainable investments in custom apparel production. With ongoing advancements, staying informed will be crucial for success in this competitive market.