DTF transfers have emerged as a game-changing method in the realm of custom apparel printing, revolutionizing the way designs are applied to fabric. With Direct-to-Film (DTF) printing, businesses can achieve vibrant, high-quality graphics that are durable and long-lasting, setting a new standard in the industry. This innovative printing technology boasts a multitude of benefits, including versatility across various material types, making it suitable for everything from t-shirts to intricate home textiles. As consumers increasingly prioritize sustainable printing solutions, DTF technology aligns with this trend by using less water and energy compared to traditional methods. By understanding the advantages of DTF transfers, businesses can harness this growth opportunity, optimizing their offerings in an ever-competitive market while promoting eco-friendly practices.

In an era where personalized merchandise is becoming ever more popular, Direct-to-Film (DTF) printing stands out as a revolutionary technique for creating custom apparel. Often referred to as direct-to-film printing, this method utilizes a specially coated film to capture designs which are then transferred onto various textile surfaces. The flexibility of DTF technology allows for high-resolution images that remain vibrant on a wide range of materials, catering to diverse customer needs. As businesses look for innovative and sustainable printing options, this approach not only meets demand but enhances their product offerings and appeal. By embracing these advanced printing capabilities, companies can remain competitive and eco-conscious in today’s fast-paced retail environment.

The Versatility of DTF Transfers in Custom Apparel

DTF transfers exemplify unmatched versatility in the realm of custom apparel. These transfers can be applied to various materials, including cotton, polyester, and even blends. This compatibility allows businesses to expand their product offerings, catering to diverse customer needs. From casual t-shirts to professional sports jerseys, the adaptability of DTF ensures that brands can serve different markets effectively. Moreover, this versatility is particularly beneficial for small businesses and startups that aim to diversify their collections without significant investment in different printing technologies.

Additionally, DTF technology facilitates not only versatile applications across fabrics but also allows for unique prints on intricate designs. The ability to print on dark fabrics without the need for specialty inks makes DTF an attractive choice for detailed custom work. This flexibility promotes creativity in design, enabling creators to push the boundaries of custom apparel printing and satisfy various client demands.

Understanding the Benefits of DTF Printing

DTF printing comes packed with numerous benefits, making it a top choice among apparel printing methods. One key advantage is the crisp and vibrant image quality it produces. DTF transfers retain their brightness and high resolution long after application, unlike some traditional printing processes that may fade over time. This durability ensures that customers receive products that not only look good but also stand the test of time, solidifying DTF printing’s place in the custom apparel industry as a reliable choice for quality.

Moreover, the cost-effectiveness of DTF transfers cannot be overstated. It allows businesses to produce high-quality items without the heavy prices associated with setup and labor costs of methods such as screen printing. DTF printing is perfect for small to medium runs, as it reduces overhead expenses while boosting profit margins—making it economically viable for both new and established brands.

Sustainability in DTF Printing

As the demand for environmentally friendly printing options grows, DTF printing stands out for its sustainability. Unlike traditional methods that consume significant resources, DTF technology uses less water and energy, aligning with the values of environmentally conscious consumers. This aspect of DTF printing not only fosters a positive image for brands but also attracts a customer base increasingly interested in sustainable practices.

Additionally, the reduced waste generated during the DTF printing process contributes to its sustainability. With precision printing that minimizes leftover materials, brands can operate more efficiently while ensuring that they meet eco-friendly standards. Embracing DTF printing aligns businesses with the movement towards sustainable fashion, ultimately promoting cleaner production methods while still appealing to the aesthetics of consumers.

Technological Innovations in DTF Printing

Innovation in DTF technology is rapidly changing the landscape of custom apparel printing. Modern printers are now equipped with enhanced capabilities, allowing them to handle larger production volumes with remarkable precision. These advancements significantly speed up the printing process, ensuring that customers receive their orders in a timely manner while maintaining high quality standards.

Furthermore, the latest developments also mean improved user interfaces and software integration, making the DTF printing process even more accessible. This is particularly advantageous for small businesses that may not have extensive resources to dedicate to training. The ease of operation enables a quicker adaptation to market demands, allowing businesses to respond swiftly to trends and customer preferences.

Market Growth and Expansion of DTF Printing Services

The market for DTF printing services is experiencing considerable growth, thanks to its user-friendly nature and cost-effectiveness. As more businesses recognize the potential of DTF technology, there is an increasing demand for customized apparel solutions across various sectors, including promotional items, team uniforms, and specialty fashion. This market expansion speaks volumes about how DTF printing is reshaping the future of custom apparel.

Additionally, the accessibility of DTF printing attracts a wider audience, ranging from small clothing lines to larger apparel brands. With lower startup costs and less complexity involved, many entrepreneurs are stepping into the custom apparel business. This surge in interest contributes to a more dynamic marketplace where creativity and innovation thrive, underscoring the versatility of DTF printing in meeting diverse consumer needs.

Why Businesses Should Choose DTF Transfers

Opting for DTF transfers not only enhances the quality of products but also ensures businesses remain competitive in the custom apparel market. The combination of stunning graphics and durability means that brands can offer high-quality merchandise that meets the expectations of discerning customers. Therefore, choosing DTF is a strategic decision for businesses looking to make their mark in the custom printing landscape.

Moreover, as market trends shift towards personalized and customizable offerings, DTF transfers equip businesses with the tools necessary to innovate. With its ease of use and fast turnaround times, companies can respond effectively to customer requests for unique designs, further solidifying their standing in an ever-evolving industry.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

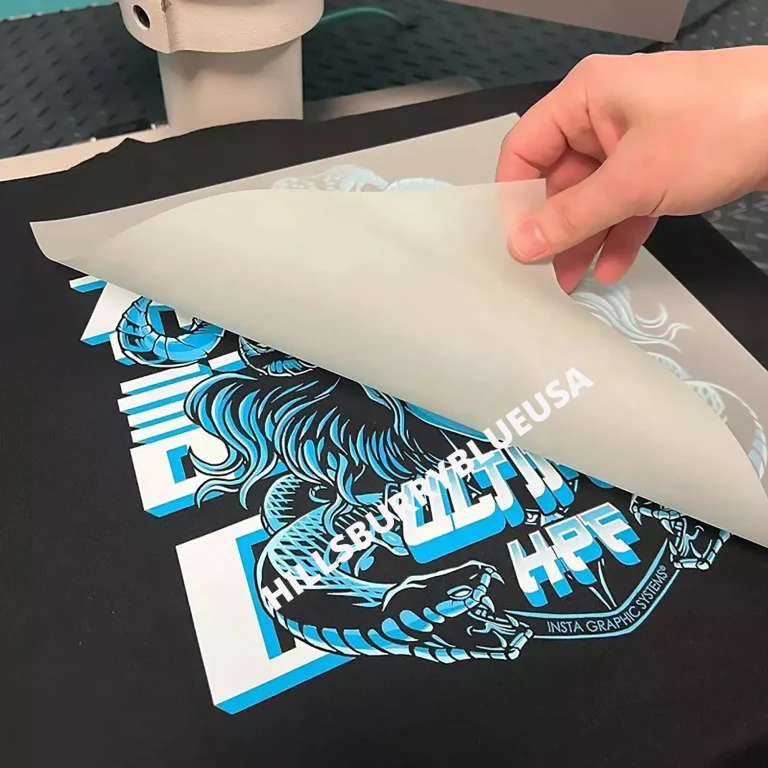

DTF transfers, or Direct-to-Film transfers, involve printing custom designs on a special film that is then heat-pressed onto fabric. This method of custom apparel printing allows for vibrant and durable graphics that can be applied to various fabrics, including cotton and polyester.

What are the main benefits of using DTF printing for custom apparel?

The main benefits of DTF printing include its versatility across different materials, ability to produce high-quality graphics, cost-effectiveness for small runs, sustainability due to lower water and energy usage, and user-friendly technology that simplifies the printing process.

How is DTF technology more sustainable compared to traditional printing methods?

DTF technology is often considered more sustainable because it uses less water and energy than traditional printing methods like screen printing. This eco-friendly approach appeals to brands aiming to reduce their environmental impact while offering customized apparel.

Can DTF transfers be applied to any type of fabric in custom apparel?

Yes, DTF transfers are highly versatile and compatible with various types of fabric, including cotton, polyester, and blends. This flexibility allows businesses to create a wide range of custom apparel, catering to diverse customer preferences.

What makes DTF transfers cost-effective for small businesses in custom apparel printing?

DTF transfers are cost-effective as they eliminate the need for multiple screens and extensive setup processes, which can be costly in traditional printing methods. This results in lower overhead costs, especially beneficial for small to medium-sized runs of custom apparel.

What innovations are currently enhancing the efficiency of DTF printing?

Recent innovations in DTF printing technology include advanced printers that improve speed and efficiency, allowing for high-volume production with precision and quick turnaround times, making it easier for businesses to meet customer demands.

| Key Advantages | Description |

|---|---|

| Versatility and Material Compatibility | Compatible with various materials like cotton and polyester, enabling diverse product offerings. |

| High-Quality Graphics | Produces vibrant colors and high resolution, resistant to fading over time. |

| Cost-Effectiveness | Lower costs for small to medium runs compared to traditional methods, increasing profit margins. |

| Sustainability | Uses less water and energy, appealing to eco-conscious brands. |

| User-Friendly Technology | Minimal training required, making it accessible for small businesses and startups. |

Summary

DTF transfers are revolutionizing the custom apparel printing landscape with their unmatched quality, flexibility, and cost-effectiveness. This innovative method not only enhances the production capabilities for businesses but also caters to the growing consumer demand for high-quality and environmentally sustainable products. As technological advancements continue to improve DTF printing, companies that adopt this printing method will position themselves for success in a dynamic market. By leveraging DTF transfers, businesses can meet diverse customer needs while maintaining a competitive edge.