In the realm of custom apparel printing, DTF transfers are emerging as a cutting-edge solution that captivates both businesses and consumers alike. This innovative DTF printing technology allows for the quick transfer of vibrant designs onto a variety of fabrics, setting a new standard for quality and efficiency in custom T-shirt printing. With its ability to produce stunning, long-lasting graphics, the benefits of DTF extend beyond aesthetics, offering cost-effective solutions for small businesses and startups. As sustainability becomes increasingly important, DTF also aligns with eco-friendly printing methods, minimizing waste while maximizing creativity. This introduction to DTF transfers will explore how this technology is reshaping the landscape of custom apparel printing and why it should be on your radar.

Direct Transfer Film, commonly referred to as DTF, is revolutionizing the custom garment industry by providing seamless and high-quality printing options. This advanced method allows intricate designs to be printed on film and then effortlessly applied to various types of apparel, breaking the barriers of traditional printing methods. The surge in the popularity of DTF printing also highlights its appeal as a sustainable printing method, catering to the growing consumer demand for eco-conscious products. Beyond just custom T-shirt designs, DTF’s versatility opens the door for unique fashion statements across diverse materials. As we delve deeper into the mechanics and advantages of DTF, it’s essential to understand its role in the broader context of custom apparel printing.

Understanding DTF Printing Technology

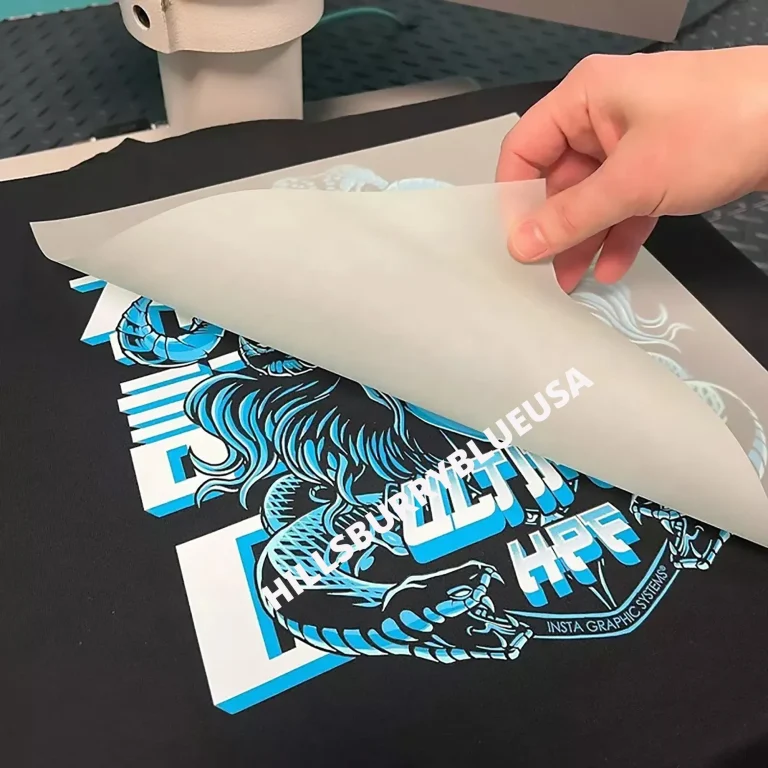

DTF printing, or Direct to Film printing, is a notable advancement in the world of custom apparel printing. This innovative technique involves printing designs onto a special film that can then be transferred onto fabric using heat and pressure. Unlike traditional methods like screen printing, DTF eliminates the need for extensive pre-treatment processes, resulting in a faster and more streamlined workflow. It offers immense flexibility, allowing for intricate designs and vibrant colors that appeal to customers seeking unique and personalized items.

The mechanics of DTF printing rely on specialized inks that adhere to various types of fabrics, including cotton, polyester, and blends. This versatility enhances the customization options available to businesses, enabling them to cater to a wide audience. Additionally, DTF technology typically requires lower investment compared to Direct to Garment (DTG) systems, making it an attractive option for startups and small businesses eager to enter the custom printing market.

The Advantages of DTF Transfers in Custom Apparel

DTF transfers offer several compelling benefits that contribute to their growing popularity in custom apparel printing. One of the primary advantages is the cost-effectiveness of DTF technology. By reducing setup costs and eliminating the need for complex preparations, businesses can achieve higher profit margins while meeting customer demands for high-quality products. Moreover, the spectacular quality produced by DTF printing ensures that every design maintains its integrity and vibrancy, drawing attention and driving sales.

Another significant advantage is the adaptability of DTF transfers to various materials. Whether printing on cotton, polyester, or blended fabrics, DTF technology demonstrates remarkable results with a wide array of garments. Furthermore, this method aligns with consumer desires for sustainable printing methods by producing less waste compared to traditional practices. As more businesses prioritize environmentally friendly options, embracing DTF technology can enhance brand reputation and attract eco-conscious consumers.

Market Trends and Growth Opportunities for DTF

The DTF printing market is experiencing remarkable growth, driven by the increasing demand for customized apparel. Reports indicate a compound annual growth rate (CAGR) of around 12% projected through 2028. This surge can be attributed to trends favoring on-demand production and personalized consumer experiences, positioning DTF printing favorably against other printing methods like DTG and screen printing. The accessibility of DTF technology means that more small to medium-sized enterprises can enter the market, expanding competition and innovation.

Key players within the DTF technology sector are also investing in advancements that enhance the quality and efficiency of DTF printing. For instance, newer machines capable of handling higher volumes without compromising print fidelity are being introduced, enabling businesses to scale operations seamlessly. These developments not only improve operational workflows but also enhance the customer experience by ensuring timely delivery of high-quality printed items, propelling the DTF market forward.

Integrating DTF with Other Custom Printing Techniques

As the DTF printing method gains traction, many businesses are exploring ways to integrate it with complementary techniques such as embroidery. Combining DTF transfers with embroidery not only enhances the visual appeal of custom apparel but also allows for a unique fusion of styles. This integration opens doors to creative possibilities for designers and marketers, granting them the flexibility to create one-of-a-kind pieces that truly resonate with consumers.

Moreover, the advent of combined technologies encourages brands to explore new niches in the apparel market. By pairing DTF with techniques like sublimation and eco-solvent printing, businesses can produce garments that are exceptionally detailed and rich in color depth. This synergy not only meets diverse consumer tastes but can also uphold sustainability efforts by reducing energy consumption and waste associated with conventional printing methods.

Challenges Facing DTF Printing Adoption

Despite the numerous benefits DTF printing offers, there are notable challenges that may hinder its broader adoption. One primary concern is the requirement for specialized inks and equipment, which can be a barrier for some businesses, particularly startups with limited budgets. This initial investment might deter potential users from transitioning from traditional methods like screen printing or DTG to DTF, despite its clear advantages.

Additionally, there is ongoing discourse regarding the environmental impact of DTF printing. While it is generally considered more sustainable than other traditional printing methods, issues may arise concerning the sourcing of materials and the lifecycle of DTF transfers. As businesses increasingly commit to sustainable practices, understanding and addressing the environmental implications of all printing technologies will be crucial in fostering trust and acceptance among consumers.

The Future of DTF Transfers and Custom Apparel Printing

Looking ahead, DTF transfers are poised to redefine the landscape of custom apparel printing. As technology continues to evolve, the quality and efficiency of DTF processes are likely to improve, making it even more appealing for businesses of all sizes. The growing trend towards personalization and customization in fashion will further fuel demand for DTF printing, ensuring that it plays a critical role in the future of the industry.

Moreover, as sustainability remains a top priority for consumers, DTF technology’s ability to produce high-quality prints with reduced waste positions it as a leader among innovative printing techniques. By investing in DTF printing, businesses can not only enhance their product offerings but also align themselves with eco-conscious initiatives, ultimately driving success in a competitive market.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct to Film transfers, are a revolutionary method in custom apparel printing where designs are printed onto a film and then heat applied to transfer them onto fabrics. This method allows for vibrant, high-quality images, making DTF transfers an excellent choice for detailed custom T-shirt printing.

What are the main benefits of DTF Printing Technology for custom apparel?

The benefits of DTF Printing Technology include cost-effectiveness, as it requires lower initial investments; superior quality with vibrant colors; versatility across various materials, including cotton and polyester; and a more sustainable printing method that generates less waste compared to traditional printing techniques.

How does DTF printing compare to other custom apparel printing methods?

DTF printing stands out compared to other methods, like screen printing and Direct to Garment (DTG) printing, due to its lower setup costs, alignment with consumer demand for customization, and the ability to produce intricate designs without extensive pre-treatments.

What types of materials can be used with DTF Transfers?

DTF Transfers are versatile and can be applied to a wide range of materials including cotton, polyester, and blended fabrics, making them suitable for various custom apparel printing applications.

Is DTF printing an environmentally sustainable option for custom apparel?

Yes, DTF printing is often seen as a more environmentally sustainable option within the industry. It generates less waste compared to traditional printing methods and aligns with the growing consumer preference for greener products.

What technological advancements are impacting DTF Transfers in the custom apparel market?

Recent advancements in DTF Transfers technology include improvements in ink formulations and printing processes that enhance durability and washability of the final products. These innovations enable businesses to meet higher volume demands while maintaining print quality.

| Key Point | Explanation |

|---|---|

| Introduction | An overview of DTF printing as a revolutionary method in custom apparel. |

| What is DTF Printing? | A process that prints designs onto film and transfers them onto fabric with heat, providing detailed graphics. |

| Rising Popularity of DTF | Cost-effectiveness and vibrant image quality are key factors driving its popularity. |

| Market Growth and Trends | Projected 12% CAGR, fueled by demand for custom apparel and on-demand printing. |

| Benefits of DTF Transfers | Includes cost-effectiveness, spectacular quality, material versatility, and environmental sustainability. |

| Technological Advancements in DTF | Improvements in inks and integration with other techniques enhance product offerings. |

| Industry Adoption | Small to medium businesses are adopting DTF due to lower costs compared to other methods. |

| Challenges Facing DTF Printing | Specialized equipment costs and environmental concerns can hinder broader adoption. |

| Conclusion | DTF transfers are a transformative method in custom apparel, promising a strong market position. |

Summary

DTF transfers are revolutionizing the custom apparel printing industry by offering a blend of quality, efficiency, and cost-effectiveness. As businesses seek to stay competitive in a rapidly evolving market, the advantages of DTF technology are becoming increasingly apparent. With its ability to produce vibrant, detailed designs across various fabric types while maintaining lower operational costs, DTF printing is set to become the preferred choice for custom apparel solutions. As the industry continues to adopt this innovative technology, DTF transfers will likely pave the way for better customization options and sustainable practices, establishing a new standard in the printing sector.