DTF transfers, short for Direct-to-Film printing, are revolutionizing the T-shirt printing landscape with their innovative approach to design application. This emerging technology offers a host of advantages that make it a top choice for custom T-shirt printing, appealing to both businesses and consumers alike. With vibrant colors and crisp details, DTF printing stands out from traditional methods, garnering interest in the digital textile printing space. As businesses increasingly seek efficient, versatile, and cost-effective solutions in T-shirt printing, understanding DTF transfers becomes essential. In essence, this method is not just a trend; it represents the future of high-quality textile printing.

Direct-to-Film printing, often referred to as DTF printing, is making waves in the apparel industry by providing alternative methods for applying graphics onto textiles. As a subset of digital textile printing, this technique harnesses several advanced technologies to offer exceptional print quality and versatility across different fabric types. The advantages of utilizing DTF technology encompass aspects such as durability, cost-effectiveness, and ease of use, making it an attractive option for businesses engaged in the customization of T-shirts and other garments. With the demand for personalized clothing on the rise, this innovative printing method positions itself as a leading solution for modern custom apparel needs. By embracing these advancements, companies can cater to evolving consumer preferences while ensuring sustainability in their production practices.

Understanding DTF Printing Technology

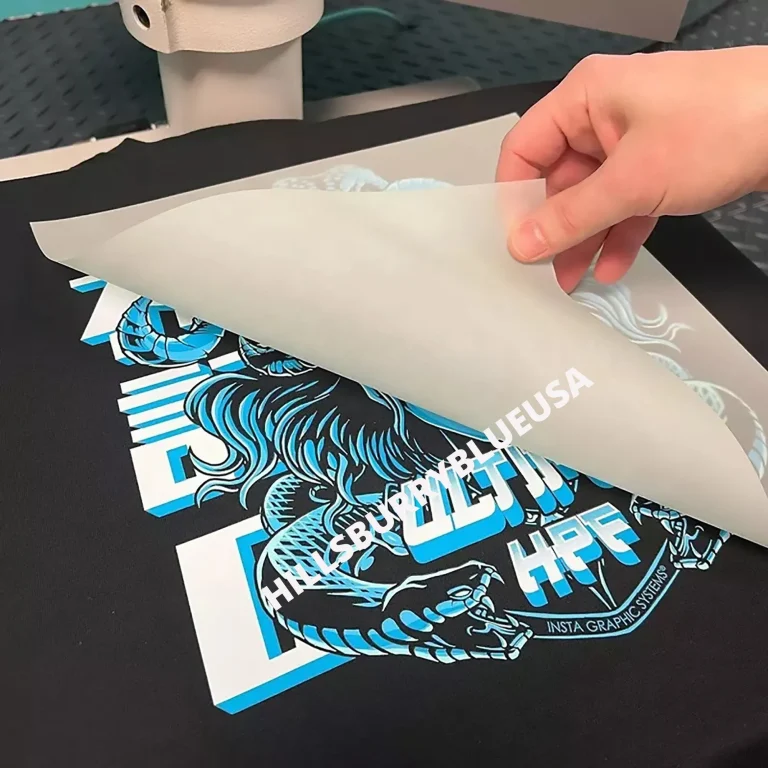

DTF, or Direct-to-Film printing, is an innovative technology that has transformed the landscape of textile printing. This process involves printing designs onto a special film that can then be heat transferred onto fabric. Unlike traditional screen printing, which often requires extensive preparation and multiple color layers, DTF simplifies the workflow significantly. This method not only saves time but also produces incredibly vibrant prints that can be applied to various fabric types, making it a versatile option for businesses and customers alike.

One of the hallmarks of DTF technology is its capacity to deliver high-resolution artwork with remarkable detail. This is particularly crucial in custom T-shirt printing, where clients often seek unique designs that capture attention. The ability to print on a wide range of materials—ranging from cotton to polyester—means that businesses can cater to diverse customer preferences, enhancing their market appeal.

The Advantages of DTF Transfers

The advantages of DTF transfers are numerous, making them a preferable choice for many businesses involved in T-shirt printing. Firstly, DTF printing is known for its remarkable quality. The prints achieved through this process are not only visually stunning but also endure the test of time. This leads to increased customer satisfaction, as buyers receive T-shirts that maintain their appearance after multiple washes, setting DTF apart from traditional methods like DTG or screen printing.

Additionally, DTF transfers are also considered cost-effective, especially for smaller businesses or startups. The initial investment for DTF printing equipment is generally lower than that for DTG, allowing new entrants to lower their barriers to entry. Moreover, the reduced ink waste and economical materials used in DTF printing contribute to ongoing savings, making this technology an appealing option for entrepreneurs aiming for sustainability and profitability in their operations.

Durability: A Key Feature of DTF Printing

Durability is a significant advantage of DTF printing, giving it an edge in the competitive T-shirt printing market. DTF technology utilizes specialized adhesives during the transfer process, ensuring that the prints adhere securely to the fabric. This means that even after repeated laundering, the designs retain their brightness and integrity, appealing to consumers who value quality and longevity in their apparel.

Furthermore, the durability of DTF prints helps businesses reduce return rates due to print quality issues. Customers appreciate products that withstand frequent use, thus fostering brand loyalty and a positive reputation. This reliability enhances the overall business model, as repeat customers are often the cornerstone of a successful T-shirt printing venture.

Environmental Sustainability in DTF Printing

As environmental concerns rise, many businesses are seeking eco-friendly alternatives in their production processes. DTF printing is well-placed to meet this demand, with many manufacturers opting for water-based inks that are significantly less harmful to the environment compared to traditional plastisol inks. This shift is not only beneficial for the planet but also resonates well with consumers who prioritize sustainability in their purchasing decisions.

By embracing DTF technology, businesses can not only reduce their ecological footprint but also attract a customer base that is increasingly conscious about the products they buy. Highlighting the eco-friendly aspects of DTF printing can serve as a unique selling proposition, enhancing brand reputation and ensuring that companies remain competitive in a crowded marketplace.

Market Trends Shaping DTF Printing’s Future

The DTF printing market is poised for significant growth, driven by technological advancements and shifting consumer preferences. As more businesses recognize the advantages of DTF printing—particularly in custom T-shirt printing—adoption rates are expected to soar. This trend is augmented by innovations aimed at improving printing efficiency and speed, which further lowers costs and enhances the value proposition for businesses.

On the consumer side, the demand for personalized apparel is on the rise, as individuals seek unique clothing options that reflect their identities. DTF printing is ideally suited to meet this demand, given its capability to produce intricate designs on a variety of materials. Businesses that leverage this trend can capitalize on the growing preference for customized products, positioning themselves advantageously in the evolving apparel market.

The User-Friendly Nature of DTF Printing

Another compelling advantage of DTF printing is its user-friendly nature. For newcomers in the T-shirt printing business, the simplified process associated with DTF reduces the learning curve typically associated with more traditional methods. The fewer steps involved in DTF printing lead to less room for errors, making it ideal for those without extensive experience in the industry.

The accessibility of DTF technology encourages more entrepreneurs to enter the custom T-shirt printing space. As businesses can quickly learn and adopt this technology, it opens up opportunities for innovation and creativity in design. This ease of use not only empowers current business owners but also attracts newcomers, strengthening the overall market for DTF transfers in the textile industry.

Frequently Asked Questions

What are DTF Transfers in T-shirt printing?

DTF Transfers, or Direct-to-Film transfers, involve a printing process where designs are printed onto a special film. This film is then applied to fabric using heat and pressure, creating vibrant, long-lasting designs on various materials. DTF printing is quickly becoming a go-to option in T-shirt printing due to its high-quality output and versatility.

What are the advantages of DTF printing compared to other methods?

DTF printing offers several advantages, including high-quality prints with vivid colors, versatility across different fabric types, and cost-effectiveness for small businesses. Additionally, DTF transfers produce durable designs that withstand washing and wear, making them ideal for custom T-shirt printing and other textile applications.

Can DTF printing be used on different types of fabrics?

Yes, DTF printing is particularly versatile and can be used on a wide range of fabrics, including cotton, polyester, and various blends. This adaptability allows businesses to cater to diverse customer preferences, providing quality custom T-shirts made from different materials.

How does DTF printing ensure print durability?

DTF printing ensures durability by using specific adhesives during the transfer process, which bond the ink to the fabric effectively. As a result, the designs maintain their vibrancy and quality over time, even after multiple washes, thus reducing the likelihood of returns and enhancing customer satisfaction.

Is DTF transfer printing an environmentally friendly option?

Yes, many manufacturers of DTF printing have shifted towards using water-based inks, which are more sustainable than traditional plastisol inks. This eco-friendly approach aligns with growing consumer demand for responsible printing practices, making DTF an appealing choice for environmentally conscious businesses.

How user-friendly is the DTF printing process for beginners?

The DTF printing process is relatively straightforward and less labor-intensive than traditional printing methods. With fewer steps involved, it allows new entrants in the T-shirt printing industry to start producing high-quality designs quickly, minimizing the learning curve and enabling efficient production.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A printing process that transfers designs onto fabric using a printed film and heat, producing vibrant, long-lasting images. |

| High-Quality Prints | Produces sharp, vivid results comparable to DTG printing, ensuring high customer satisfaction. |

| Versatility Across Materials | Applicable to a variety of fabrics (cotton, polyester, blends), making it suitable for a wider audience. |

| Cost-Effectiveness | Lower initial and ongoing costs compared to DTG, with efficiency leading to reduced ink wastage. |

| Durability of Prints | Long-lasting designs that resist fading and wear, enhancing customer satisfaction and reducing returns. |

| Environmentally Friendly Options | Utilizes water-based inks, aligning with consumer preferences for sustainable practices. |

| Ease of Use | Simpler than traditional methods, making it accessible for beginners. |

Summary

DTF Transfers are transforming the landscape of T-shirt printing, blending high-quality results with versatility and cost-effectiveness. This innovative technology not only delivers vibrant and durable prints but also caters to the growing demand for eco-friendly practices in the industry. As businesses continue to embrace DTF Transfers, they are well-positioned to meet customer preferences for customized apparel, paving the way for sustainable success in the competitive textile market.