DTF transfers, or Direct-to-Film transfers, are reshaping the landscape of garment decoration with their innovative approach to design. Tailored for everyone from industry professionals to DIY enthusiasts, these transfers allow you to achieve high-quality, vibrant designs that stand out. Understanding the nuances of DTF transfer sizes is crucial for optimizing your artistic vision and fabric compatibility, ensuring that your creations are not just visually appealing but also durable. This guide will cover the selection process for these custom DTF transfers, delving into how the choice of size impacts design effectiveness and overall garment aesthetics. As we explore the world of DTF printing quality and transfer printing techniques, you’ll gain insights that will enhance your creativity and design workflow.

In the realm of garment customization, direct-to-film decoration methods are gaining traction, offering versatility and a vivid palette for creative projects. This technique, often referred to as DTF printing, enables artists and designers to print their ideas onto a specialized film that can be easily applied to various fabrics. The importance of choosing the right dimensions for these transfer prints cannot be overstated, as it directly influences the outcome of your designs. Whether you are creating one-off pieces or commercial apparel, understanding patterns, compatibility with fabric types, and the impact of size on visual appeal is essential. As we dive deeper into DTF transfer options, let’s explore the innovative strategies that can elevate your garment designs to new heights.

The Basics of DTF Transfer Printing Techniques

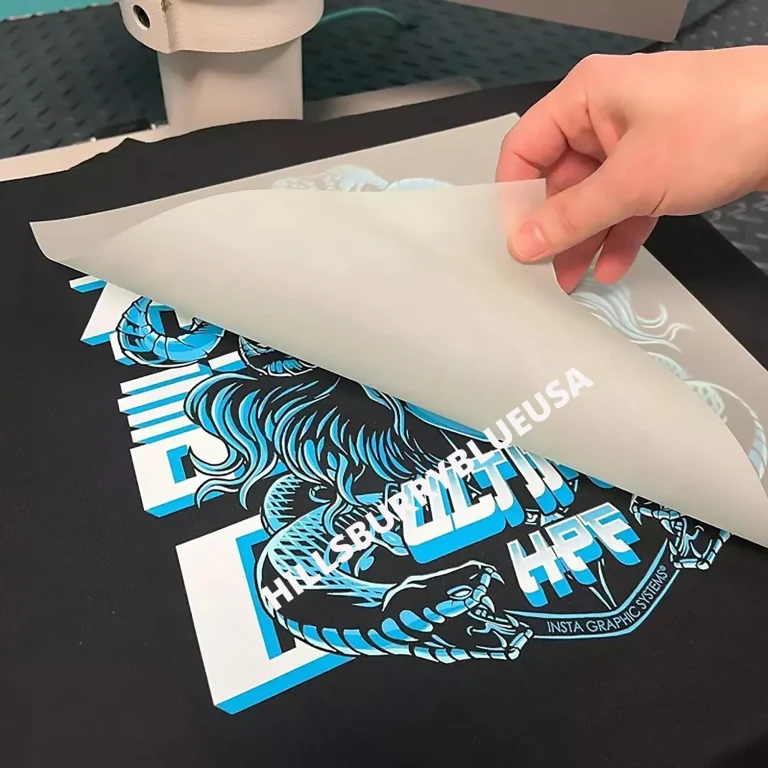

Direct-to-Film (DTF) transfers are a modern solution in the realm of garment decoration, combining advanced printing technology with practical applications. This technique utilizes special films to achieve vibrant colors and striking designs. The process starts with printing your graphics onto a film which is then coated with adhesive powder before being heat-pressed onto the fabric. This unique method allows DTF transfers to exhibit outstanding durability and flexibility, making it a popular choice for both small-scale projects and larger commercial applications.

One of the most appealing aspects of DTF transfer printing is its versatility in fabric applications. Unlike traditional screen printing, which can be restrictive in terms of fabric types, DTF transfers can be used on a wide array of materials including cotton, polyester blends, and even blends with elastane. This broad compatibility opens up creative opportunities for designers, allowing them to apply intricate designs onto garments, sportswear, and promotional items with ease.

Exploring DTF Transfer Sizes: From Small to Large

Selecting the appropriate size for your DTF transfers is crucial for ensuring maximum visual impact and aesthetic appeal. Smaller transfers typically work well on t-shirts and caps, where subtle designs enhance the garment’s overall look without overwhelming the viewer. In contrast, larger transfers are excellent for creating bold statements on jackets and hoodies, effectively serving as focal points of the apparel. Understanding the relationship between design size and garment type is essential for achieving the desired effects.

When considering DTF transfer sizes, one must also take into account the intended placement on the garment. For instance, a large transfer might be perfect on the back of a hoodie, showcasing an eye-catching graphic that can be easily appreciated from a distance. Meanwhile, smaller designs might be best suited for the chest area or sleeve, adding an element of sophistication. This strategic consideration of both size and placement helps in crafting a well-balanced and visually appealing piece that resonates with the audience.

Design Complexity and DTF Transfer Size

The complexity of your design can significantly dictate the optimal size for DTF transfers. High-resolution images can be rendered in large formats without losing quality, making them ideal for expansive prints that capture attention. On the other hand, intricate patterns or detailed graphics may require careful scaling down to maintain clarity. Designers should meticulously assess their designs, ensuring that important elements remain distinct and recognizable, especially when adjusting sizes for different fabric types.

Moreover, it’s worth noting that overly large transfers can distort fine details, which might compromise the overall aesthetic and intended message of the artwork. Intricacy is often lost in translation when scaling beyond optimal size limits. Therefore, balancing design complexity with the chosen size is vital in ensuring that the final product meets both visual and tactile expectations.

Current Market Trends in DTF Transfers

The landscape of garment decoration has seen a marked shift towards personalization, reflecting consumers’ desires for unique, custom DTF transfers that express individual style. Market trends indicate a growing demand for custom sizes that deviate from traditional norms, allowing designers to tailor their work to specific consumer preferences. This customization includes various dimensions suited to different types of apparel, providing endless opportunities for creativity and innovation.

Furthermore, advancements in DTF printing technology have enabled the production of smaller, more intricate transfers that can be applied to an increasing range of products, including accessories like bags and headwear. This expansion opens new pathways for designers, allowing them to explore novel applications for their designs and meet the diverse needs of the market. As personalization continues to gain traction, the customization of DTF transfer sizes becomes a crucial element in staying competitive.

Best Practices for Optimal DTF Transfer Selection

Making informed choices when selecting DTF transfer sizes involves adhering to best practices that streamline the design process. Engaging with reputable suppliers can provide valuable insights into optimal size selections tailored to your projects. Their expertise can help navigate the potential pitfalls associated with certain designs and fabric combinations, ensuring the highest quality outcomes for your creations.

In addition to consulting with suppliers, conducting test runs on various fabrics can be incredibly beneficial. This practice allows designers to assess how different DTF transfer sizes appear when applied to the chosen fabric, giving a preview of the final product’s look and feel. Testing can help identify the perfect size that doesn’t compromise the design’s integrity while delivering the desired impact, which is especially important for bulk production.

Ensuring Quality and Aesthetic with DTF Transfers

The quality of DTF transfers is crucial in determining the functionality and appeal of the final product. High-quality transfers not only enhance the durability of the design but also significantly affect the tactile experience. Using advanced printing techniques ensures that the colors and details of your graphic remain vibrant and intact over time. Achieving quality results begins with the careful selection of transfer size, ensuring it is compatible with the design resolution and fabric of choice.

Additionally, maintaining high standards in DTF printing quality involves regular equipment maintenance and the use of premium materials. By prioritizing quality in both the transfer and the adhesion process, designers can produce garments that not only look fantastic but also withstand wear and washing without significant fading or peeling. Delivering exceptional products relies directly on the attention given to every facet of the DTF transfer process.

Frequently Asked Questions

What are DTF transfers and how do they work in garment decoration?

DTF transfers, or Direct-to-Film transfers, are a revolutionary method of garment decoration that involves printing designs onto a specialized film and then heat pressing it onto fabric. This technique allows for vibrant colors and intricate designs, making it a popular choice among designers and hobbyists alike for custom apparel.

How do I choose the right DTF transfer size for my projects?

Choosing the right DTF transfer size depends on several factors including the design impact you want to achieve, the placement on the garment, and fabric compatibility. Larger transfers are more suitable for bold designs on hoodies or jackets, while smaller transfers work well for t-shirts or caps.

What factors should I consider when selecting DTF transfer sizes?

When selecting DTF transfer sizes, consider the visual impact of the design, the placement on the garment (like front or back), and the fabric type to ensure the best DTF printing quality. Understanding these factors will help you align your design with the intended garment style.

Can different fabrics affect the result of my DTF transfers?

Yes, different fabrics can significantly affect DTF transfer results. Cotton blends and polyester generally yield the best outcomes, while the size of the transfer can also influence the feel and durability—larger transfers may feel heavier and impact wear comfort.

What are the latest trends in DTF transfers?

Recent trends in DTF transfers include a surge in personalized and custom DTF transfers that cater to individual preferences. Additionally, the advancements in DTF printing technology have expanded the application of transfers to both small items like caps and larger garments, allowing for more creativity.

What are some best practices for selecting sizes for DTF transfers?

Best practices for selecting DTF transfer sizes include consulting with DTF suppliers for expert advice, testing designs on sample fabrics beforehand, and ensuring that your transfer size complements the complexity and quality of your design to achieve optimal results.

| Key Point | Explanation |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on specialized film, which is then heat-pressed onto fabric, allowing for vibrant, durable designs. |

| Choosing the Right Size | Size affects visual impact. Larger transfers suit bold graphics while smaller ones suit subtle designs. |

| Placement Importance | Proper placement enhances aesthetic appeal; large transfers are good for backs, while smaller ones suit chest areas. |

| Fabric Compatibility | Fabric type affects transfer interaction. Cotton blends and polyester work best. Size can impact comfort. |

| Design Complexity and Resolution | High-res images can be larger without loss of quality, but intricate designs may not suit larger transfers. |

| Market Trends | A shift toward personalized DTF transfers allows for unique designs and varying dimensions based on projects. |

| Best Practices | Consult suppliers and test samples before large orders to ensure compatibility and quality. |

Summary

DTF transfers are a game-changer in garment decoration, providing unmatched versatility and vibrancy. Selecting the right size for DTF transfers is crucial for maximizing design impact and ensuring compatibility with various fabrics. By understanding the relationship between transfer size, design intricacy, and fabric type, you can make informed decisions that align with your creative vision. As market trends lean towards personalization and unique designs, embracing the potential of DTF transfers will allow you to bring your innovative ideas to life. Whether for personal projects or commercial lines, these insights ensure your DTF transfers not only look great but also resonate with your audience.