Understanding the importance of DTF transfers size is crucial when diving into the vibrant world of apparel customization. DTF, or Direct to Film, transfers not only allow for intricate designs to be flawlessly printed but also demand careful consideration of their dimensions to achieve the best visual impact on fabric. The right transfer size can significantly enhance your apparel DTF designs, ensuring they are striking and appropriately proportioned to the garment. In this guide, we will explore how to choose the ideal size for DTF transfers in your clothing line, encompassing various factors such as design complexity and garment type. By mastering the art of DTF transfer sizing, you will elevate your creations and cater to the evolving tastes of customers.

In the realm of custom garment decoration, selecting the appropriate dimensions for your DTF transfers is paramount. This method, commonly referred to as Direct to Film printing, facilitates the application of vivid designs onto textiles, but the success of your designs heavily relies on understanding the nuances of transfer sizing. Considering factors such as the type of clothing and the specific characteristics of the designs can vastly improve the overall aesthetic of your apparel. This article will provide insight on how to effectively gauge transfer sizes, ensuring that your creations resonate well with your target audience. Embracing the art of sizing not only amplifies the visual appeal but also enhances the functionality of your apparel designs.

Importance of DTF Transfer Sizing in Apparel Customization

When it comes to apparel customization, understanding the significance of sizing for DTF transfers cannot be overstated. Each piece of clothing has its unique dimensions and styles which dictate how a design can be best showcased. A well-sized DTF transfer enhances the visual appeal of the garment while ensuring that the intricate details of the design do not get lost. If the transfer is either too large or too small, it can distract from the garment’s overall appearance, potentially driving customers away.

Furthermore, appropriate sizing boosts the durability of the transfer itself. A correctly sized DTF transfer ensures proper adherence during heat application, reducing the risk of peeling or fading over time. For apparel businesses, this means that not only will the designs look better, but they will also stand the test of repeated wear and washing, ultimately contributing to customer satisfaction and repeat sales.

Frequently Asked Questions

What factors should I consider when deciding on DTF transfer sizes for my apparel?

When choosing DTF transfer sizes for your apparel, consider design complexity, placement, and the type of garment. Larger prints work better on bigger items like hoodies, while smaller designs are suitable for fitted tees. Make sure the transfer is proportionally sized to the garment’s dimensions.

How does the placement of DTF transfers affect their size on garments?

The placement of DTF transfers significantly affects perceived size. For example, a centered design on a t-shirt may need to be larger than one applied to the sleeve. Experimenting with placements will help ensure your designs look their best.

Are there industry standards for DTF transfer sizing on apparel?

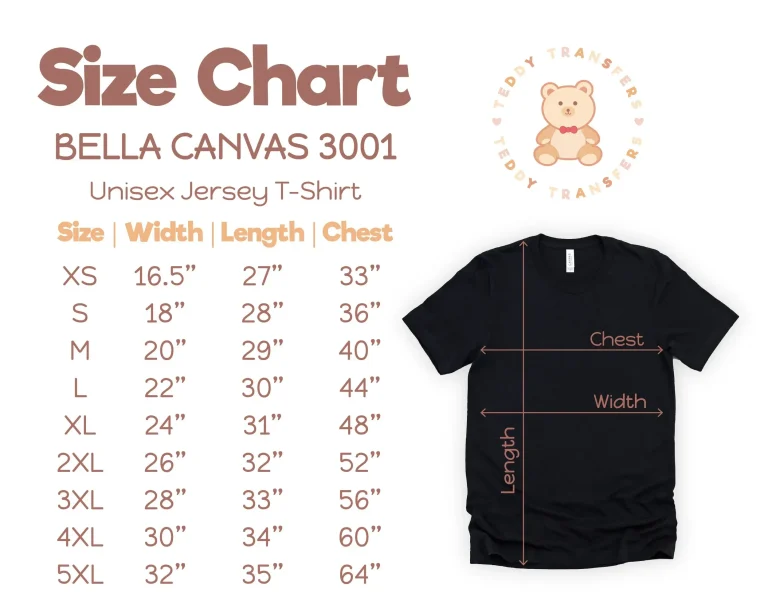

There aren’t strict industry standards for DTF transfer sizes, but referencing size charts and templates can guide you. These tools help determine suitable dimensions based on common apparel sizes and styles.

What should I test before finalizing DTF transfer sizes for production?

Before mass production, create samples with various DTF transfer sizes and placements. This testing phase allows you to see how transfers adhere to fabric and how they visually impact different garment types.

How do different garment styles influence DTF transfer sizing?

Different apparel styles have distinct requirements for DTF transfer sizes. For example, activewear has unique sizing needs compared to casual tees. Understanding your target audience and garment type is crucial in selecting the right transfer size.

Can design software help in selecting the right DTF transfer size?

Yes, using design software like Adobe Illustrator or Canva allows you to visualize how DTF transfers will appear on various fabrics. These tools help you adjust size and placement before production, making the design process more efficient.

| Key Points | Description |

|---|---|

| Understanding DTF Transfers | DTF printing transfers designs onto a special film that adheres to fabric, making the size crucial for design aesthetics. |

| Sizing Considerations | Design complexity, placement, and garment types are critical factors in determining the ideal transfer size. |

| Testing and Prototyping | Creating samples and testing different sizes ensures appropriate adherence and aesthetic appeal on fabric. |

| Industry Standards | While no strict standards exist, size charts and templates can guide in selecting transfer sizes. |

| Tools and Resources | Design software like Adobe Illustrator can help visualize and adjust transfer sizes effectively. |

Summary

DTF transfers size is a fundamental aspect of creating captivating garment designs tailored to your apparel business. Properly selecting transfer sizes can significantly enhance the look and marketability of your products. By considering design complexity, placement on the garment, and the specific type of apparel, you can achieve the perfect balance for your designs. Prototyping different sizes ensures that your transfers maintain their integrity and visual appeal after production. Leveraging industry resources and design tools can streamline the decision-making process, setting your business up for success in the competitive world of apparel customization.