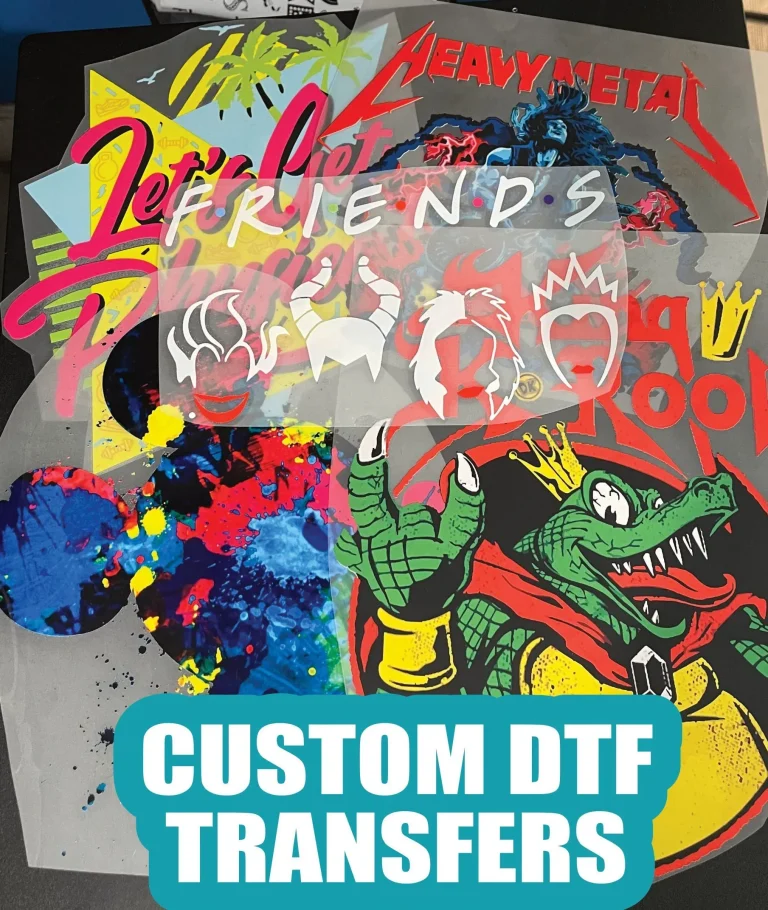

DTF transfers, or Direct-to-Film transfers, have revolutionized the custom apparel industry by providing a high-quality printing solution that is both vibrant and detailed. This innovative printing technique excels in delivering colorful designs that stand out on various fabrics, making it a favorite among small businesses and established brands alike. With the use of a heat press and specialized adhesive powder, DTF transfers ensure that your custom apparel can withstand the test of time, both in durability and aesthetics. This guide will take you through the essential steps needed to perfect DTF transfers, enhancing your product offerings and maximizing customer satisfaction. Embrace this cutting-edge technology to elevate your business and tap into the growing market for bespoke fashion.

Direct-to-Film transfers, often referred to as DTF printing, is quickly gaining traction as a go-to method for crafting custom designs on textiles. With its unique ability to produce eye-catching prints on a wide variety of materials, this approach stands out as a clever solution for apparel customization needs. Using a combination of specially formulated adhesive powder and a consistent heat press application, users can achieve stunning results that endure. Additionally, methods such as heat transfer printing and film transfer techniques are complementing the diverse world of custom garment creation. Explore how mastering these printing technologies can lead to substantial rewards for your apparel business.

The Versatility of DTF Printing

DTF printing, or Direct-to-Film transfers, is increasingly becoming a preferred choice among those involved in custom apparel manufacturing. The versatility of DTF printing allows designers to work on a plethora of fabric types including cotton, polyester, and even blends, which broadens the potential product offerings for businesses. Whether producing t-shirts, hoodies, or bags, the ability to seamlessly print on different materials opens up an array of possibilities for customization.

Moreover, the DTF transfer process enhances the potential for creativity. Artists can produce intricate and colorful designs without the constraints often imposed by traditional screen printing methods. Since the DTF technique provides sharp detail and vibrant colors, businesses can confidently take on complex designs and cater to diverse customer preferences, keeping their apparel offerings fresh and appealing.

Essential Equipment for Successful DTF Transfers

To embark on the journey of DTF transfers successfully, having the right equipment is critical. At the forefront is a specialized printer, ideally a modified inkjet that handles high-quality water-based inks. Alongside the printer, utilizing high-quality transfer film designed specifically for DTF applications is essential to achieving optimal results. These films ensure that the prints not only adhere well but also showcase the best color and detail during application.

Additionally, other critical components include adhesive powder and a reliable heat press. The hot-melt adhesive powder is crucial as it ensures a strong bond between the ink and the film, as well as between the film and the fabric. Investing in a high-quality heat press that allows for consistent temperature and pressure will also significantly improve the quality of your DTF transfers, making it an indispensable tool for any serious custom apparel business.

Design Preparation for DTF Printing

The design preparation stage is vital in the DTF printing process, as it sets the foundation for the quality of the final product. Utilizing graphic design software such as Adobe Illustrator or CorelDRAW ensures that your artwork is set up correctly for printing. It’s essential to work in CMYK color mode to align with printing standards and achieve accurate color representation. Additionally, setting the resolution to a minimum of 300 DPI ensures that the prints remain sharp and detailed.

Another critical aspect of design preparation involves mirroring the design before printing. This step is crucial, as it ensures that the graphic appears correctly once transferred to the apparel. By carefully preparing the design elements, businesses can avoid costly mistakes and produce a high-quality finished product that meets customer expectations.

Mastering the Printing Process for DTF Transfers

Once your design is finalized, the printing process is where the magic begins. It’s essential to follow specific procedures to ensure the transfer happens seamlessly. After mirroring the image, print it on the specialized DTF film, taking care to adhere to the printer’s guidelines. This will guarantee that colors are vibrant and details are precise, which are crucial elements for successful custom apparel.

After printing, applying the hot-melt adhesive powder immediately while the ink is still wet is equally significant. Properly curing this adhesive enhances the durability of the print, ensuring that it resists fading and peeling when subjected to washing and wearing. Following up this process with a professional transfer application will solidify the quality of the final product, meeting the high standards expected in custom apparel.

Executing a Flawless Transfer Process

The actual transfer process is a pivotal moment in DTF printing, where a well-executed transfer results in a professional finish. Begin by preheating the heat press to the specified temperature, usually between 315-350°F, and ensuring the pressure is set correctly for the material being used. Proper positioning of the printed DTF film onto the substrate is crucial; misalignment can lead to a subpar outcome.

Once the film is securely placed, applying pressure for the correct duration of 12-15 seconds will allow the adhesive to bond effectively with the fabric. Following the transfer, allow the substrate to cool before peeling away the film. A controlled and gentle peel will reveal a crisp and clean transfer that promises durability and vibrancy, aspects that are essential in the competitive custom apparel market.

Post-Transfer Care for Longevity and Quality

After successfully completing a DTF transfer, it’s important to educate customers on post-care to ensure the longevity of their custom apparel. Advising them to wash the items inside out in cold water will help protect the print and fabric from damage. It’s also beneficial to recommend avoiding bleach and harsh detergents, as these can break down the adhesive and lead to premature fading.

Additionally, encouraging air drying instead of machine drying will help maintain the quality of both the print and the garment. By providing clear care instructions, businesses can not only enhance customer satisfaction but also reduce the likelihood of complaints related to print durability. This knowledge can build customer loyalty, turning first-time buyers into repeat customers.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing method that involves printing designs onto a special film which is then transferred onto fabric using a heat press. This technique is highly effective for custom apparel, yielding vibrant colors and detailed images suitable for a range of fabrics like cotton and polyester.

What materials do I need for DTF printing and transfers?

To successfully perform DTF transfers, you will need a modified inkjet printer, specialized DTF transfer film, hot-melt adhesive powder, and a quality heat press. These materials are essential for achieving high-quality, durable prints on custom apparel.

How do I prepare a design for DTF printing?

When preparing a design for DTF printing, use graphic design software to create or modify your artwork. Ensure it is in CMYK color mode and at a high resolution of at least 300 DPI. Remember to mirror the image before printing to ensure it appears correctly on the final custom apparel.

What is the process of applying DTF transfers to fabric?

The application process for DTF transfers involves several steps: first, preheat your heat press; align the printed film on the fabric; press it with medium to heavy pressure for about 12-15 seconds; and then peel away the film after cooling slightly. This method is crucial for achieving a professional finish on custom apparel.

What are some care tips for garments made with DTF transfers?

To maintain the quality of garments with DTF transfers, advise customers to wash their items inside out in cold water and avoid bleach or harsh detergents. Air drying is preferred to preserve the print and fabric integrity, ensuring longevity and vibrancy of custom designs.

What are the recent advancements in DTF printing technology?

Recent advancements in DTF printing technology focus on enhancing durability and washability of the transfers. New ink formulations and adhesive powders are being developed to provide improved vibrancy and longevity, helping businesses offer better quality custom apparel to their clients.

| Step | Description | Tips/Considerations |

|---|---|---|

| 1. Understanding DTF Transfers | DTF printing involves transferring vibrant designs from a special film to fabric using heat. | Ideal for colorful prints on various textiles. |

Summary

DTF transfers are a groundbreaking method in the custom apparel industry, enabling businesses to create vibrant, durable prints on a variety of fabrics. With the ability to achieve detailed designs quickly and efficiently, mastering DTF transfers is essential for businesses looking to enhance product offerings and customer satisfaction. From understanding the required materials and equipment to perfecting the printing and transfer processes, this guide equips you with all the knowledge needed to succeed. By effectively implementing DTF transfer techniques, you can ensure high-quality results that meet customer demands while staying ahead of the competition.