DTF Transfers, or Direct-to-Film transfers, are rapidly becoming the go-to solution for those looking to create stunning prints on textiles. This innovative printing method leverages the DTF transfer process to combine vibrant designs with exceptional durability, making it ideal for businesses of all sizes. By following specific DTF printing steps, users can achieve high-quality results that stand the test of time, from custom apparel to intricate designs on various fabrics. Unlike traditional heat transfer printing methods, DTF print technology offers unparalleled versatility, allowing for easy application on different textile types. In this post, we will explore the nuances of DTF Transfers, empowering you to elevate your printing game.

Known for its efficiency, the process involved in Direct-to-Film printing is taking the textile industry by storm. Often referred to as DTF or film-based transfers, this technique allows creators to effortlessly apply intricate designs to garments and other fabric items. The procedure encapsulates a series of steps, ensuring that each print not only looks exceptional but also endures the test of time. By understanding the mechanics behind this innovative method, including the application of heat and adhesive bonding, users can optimize their results and offer custom prints that meet diverse consumer demands. As we delve deeper into these film printing techniques, you’ll discover how to harness their full potential.

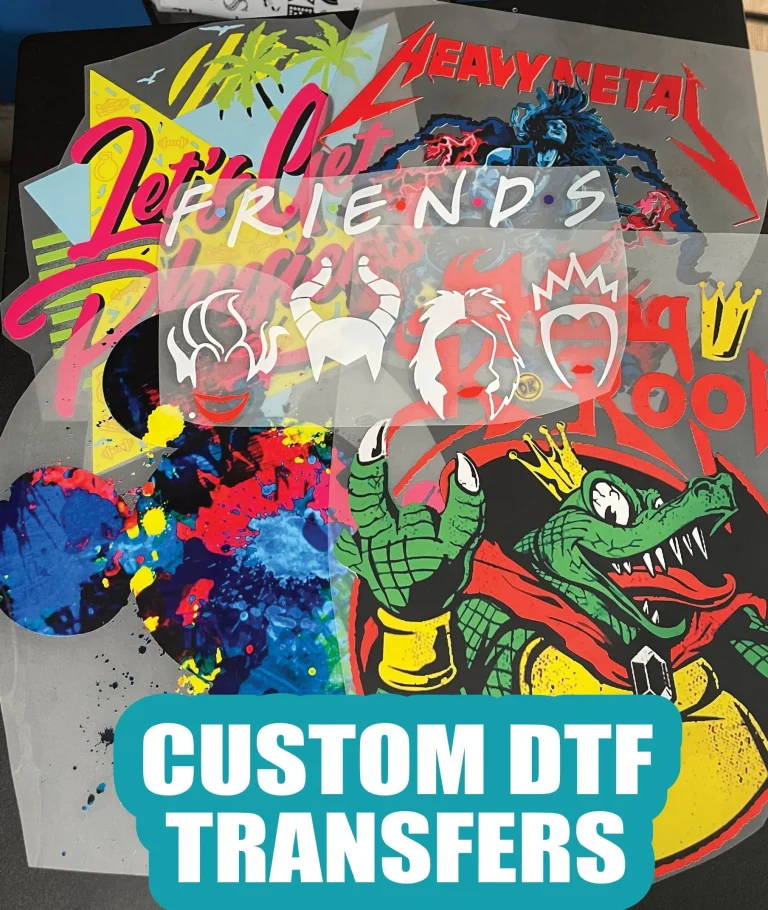

The Basics of DTF Transfers Explained

Direct-to-Film (DTF) transfers is a printing method that involves creating detailed designs that are then transferred onto fabric through a unique multi-step process. This technique leverages high-quality DTF printing technology, allowing for vibrant and durable prints that cling well to various fabric types, including cotton and polyester blends. Understanding the principles of DTF transfers is essential for businesses looking to explore contemporary textile printing, as it streamlines workflows while offering impressive output results.

At the core of DTF transfers lies the DTF transfer process, which encompasses design creation, printing, and application. This method differs significantly from traditional heat transfer printing and screen printing because it utilizes a specialized transfer film. DTF technology reduces ink waste and caters to intricate designs with rich colors, giving users an edge in a competitive market.

Frequently Asked Questions

What is the DTF transfer process in textile printing?

The DTF transfer process involves applying designs to fabric through a detailed method including graphic design, printing on special transfer film, applying hot-melt adhesive, and using heat to bond the design securely to the fabric. This innovative approach is known for producing vibrant and durable prints.

How do you create a design for DTF printing?

To create a design for DTF printing, use graphic design software like Adobe Illustrator or CorelDRAW. Ensure to save your files in suitable formats such as PNG or TIFF, which help maintain quality. It’s important to check color contrast for visibility on the final fabric.

What are the key steps in the DTF printing process?

The key steps in the DTF printing process include: 1) Design Creation, 2) Printing on Transfer Film, 3) Applying Hot-Melt Adhesive, 4) Cooling and Preparing for Transfer, 5) Heat Transfer to Fabric, and 6) Peeling off the Film post-transfer.

What materials can be used with DTF transfers?

DTF transfers can be applied to a variety of fabric types including cotton, polyester, and blended fabrics. This flexibility makes DTF printing suitable for diverse garment types, facilitating a broad range of customized applications.

What are the benefits of using DTF transfer technology?

Benefits of DTF transfer technology include versatility for various fabric types, high durability that withstands multiple washes, and cost-effectiveness suitable for both small business and large-scale production, making it an attractive option for customized clothing.

How does heat application affect DTF transfers?

Heat application is crucial in the DTF transfer process. Using a heat press at approximately 320°F (160°C) for 15-20 seconds ensures that the design adheres properly to the fabric, preventing issues like peeling or bubbling, which affects the longevity of the print.

| Step | Description | Key Considerations |

|---|---|---|

| 1. Design Creation | Creating a digital design using software like Illustrator. | Use quality formats (PNG, TIFF) and ensure color contrast. |

| 2. Printing on Film | Print the design on transfer film using a DTF printer. | Mirror text designs before printing to ensure correct alignment. |

| 3. Applying Adhesive | Apply hot-melt adhesive powder to wet ink on the film. | Ensure even application to avoid patchy transfers. |

| 4. Cooling and Preparation for Transfer | Cool the film to solidify adhesive and trim excess film. | Proper trimming is essential for a clean transfer. |

| 5. Heat Transfer to Fabric | Use a heat press at 320°F (160°C) for 15-20 seconds. | Apply proper pressure to prevent peeling or bubbling. |

| 6. Peeling Off the Film | Carefully peel the film to reveal the embedded design. | A second heat press may be needed to ensure durability. |

Summary

DTF Transfers offer a modern and efficient approach to custom textile printing that combines creativity with precision. This method not only allows for vibrant and durable prints but also adapts seamlessly to various fabric types, making it a versatile solution for businesses of all sizes. By mastering the DTF transfer process, from design through to application, companies can significantly enhance their product offerings and respond to market demands with agility. As technology continues to advance in this field, embracing DTF transfers can create a competitive edge and open doors to new opportunities in the ever-evolving world of garment printing.