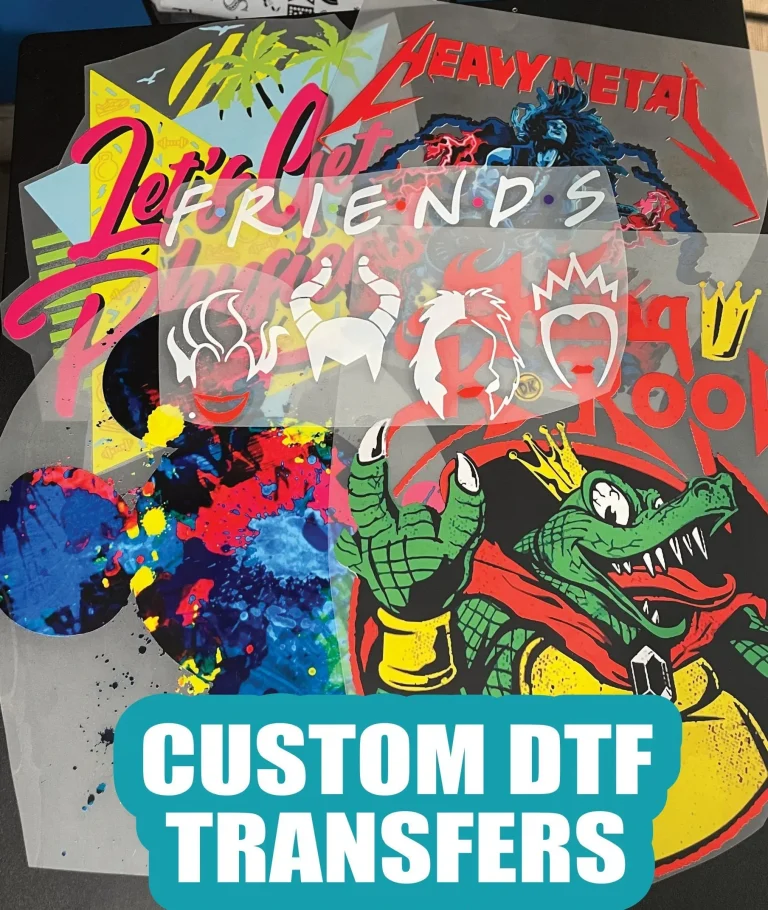

DTF transfers, or Direct-to-Film transfers, have taken the printing world by storm, bringing innovative DTF printing techniques into the limelight. This versatile method allows individuals to create intricate, high-quality designs directly on various fabrics, making it a popular choice among both beginners and seasoned professionals. With DTF transfer applications extending from custom apparel to unique home decor, this approach offers a seamless way to produce vibrant, durable prints. In this guide, we will unravel the essentials of DTF printing, introducing beginners to the basics while also catering to the needs of experts looking to refine their skills with advanced DTF techniques. Join us as we explore this exciting realm of printing that continues to empower creative expression across various textiles.

Also known as Direct-to-Film printing, DTF transfers are revolutionizing how designs are transferred onto fabric, offering a dynamic alternative to traditional methods. This modern printing approach employs specialized DTF printing technologies to produce stunning visuals that can be applied to an array of materials including garments, tote bags, and other items. With its user-friendly nature, DTF printing for beginners allows newcomers to easily engage in the creative process, while advanced practitioners can explore intricate DTF printing techniques for unique results. Whether you’re keen on understanding the fundamental concepts or delving into more sophisticated strategies, this guide provides valuable insights into the world of film transfers and their limitless applications.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is an innovative technique that bridges the gap between traditional screen printing and digital printing. It involves printing designs onto a specialized film, which is then transferred onto fabric using heat and pressure. One of the remarkable features of DTF printing is its ability to produce vibrant colors and intricate details, making it a favorite among designers and small businesses. As the printing technology evolves, understanding the basic principles will empower both beginners and seasoned printers to effectively utilize this technique.

For those new to DTF printing, the process begins with selecting high-quality DTF films and inks. Unlike other printing techniques, DTF printing allows for greater creativity as it can produce multi-color designs without a significant increase in production costs. The films used in this process are designed to adhere well to various fabrics, enabling the transfer of images onto t-shirts, bags, and home décor with ease. Understanding the mechanics behind this process sets a strong foundation for achieving stunning print outcomes.

Essential Equipment for DTF Printing

A successful DTF printing project requires specific equipment to ensure the highest quality results. The core of the operation is a modified inkjet printer that accommodates DTF inks. These specialized inks are formulated to provide brilliant color payoff while maintaining flexibility and durability on the fabric. In addition to the printer, investing in a reliable heat press is essential. This equipment offers the necessary temperature and pressure control required for effective transfers.

Beyond printers and heat presses, other essential tools include specialty DTF film, which is key to the printing process, and adhesive powder that binds the printed image to the fabric when the transfer takes place. Beginners can consider starting with a comprehensive DTF printing kit that contains all necessary elements to simplify the initial setup process. Experienced printers might explore various brands to find the most suitable components for their specific needs.

Step-by-Step Guide for DTF Printing Beginners

Beginning with DTF printing can be a thrilling journey filled with creativity and resourcefulness. Start by designing your artwork using vector graphics software like Adobe Illustrator, ensuring that the resolution is compatible with high-quality print output. Once the design is ready, load the specialty film into the printer and print the artwork, remembering that colors may look different on the film compared to the fabric. This step is essential for achieving accurate color representation.

After printing, carefully apply the adhesive powder over the wet ink, ensuring even coverage before shaking off any excess. Following this, utilize your heat press, preheat it to the recommended temperature, and position the film on the target fabric for transfer. The final steps involve cooling the fabric post-pressing before peeling away the film, ensuring the design has adhered properly. By following this guide, beginners can navigate through DTF transfers efficiently and produce impactful results.

Exploring Advanced DTF Techniques

As you gain confidence in DTF printing, consider experimenting with advanced techniques to elevate your designs. One such technique is color optimization, which involves fine-tuning the color settings in your printer for better saturation and vibrancy. Achieving true-to-life colors can significantly impact the appeal of your finished products, making them stand out in a competitive market.

Another intriguing approach is layering prints, allowing you to create multi-dimensional designs that add depth and uniqueness. This technique can enhance the texture and visual interest of your transfers, appealing to customers looking for something beyond flat designs. Regular maintenance and troubleshooting as issues arise will ensure a smooth printing experience and consistent output quality.

Finally, don’t hesitate to think outside the box. DTF transfers can be applied to a variety of applications beyond clothing, making it a versatile choice for custom products. Exploring different substrates such as tote bags, home décor items, and other textiles opens up new avenues for creativity and market expansion.

Best Practices for Successful DTF Printing

Achieving successful DTF prints requires adherence to best practices that enhance the overall outcome. Begin by pre-pressing your fabric to eliminate moisture and wrinkles, as this preparation is vital for optimal adhesive bonding. Properly adhering to the manufacturer’s guidelines for film and powder ensures that the resulting prints are durable and of high quality.

Regular maintenance of your printing equipment also cannot be overstated. A well-maintained printer and heat press lead to fewer issues, improved reliability, and consistently superior print quality. Testing your transfers on different fabric types will help determine the best materials for your designs, ensuring successful application and longevity of the prints.

Getting Started with DTF Transfer Applications

Once you’ve grasped the basics of DTF printing, it’s crucial to explore various applications where DTF transfers shine. From custom apparel to promotional merchandise, the versatility of this technique allows for creative expression across a wide range of products. This adaptability not only attracts customers but also enables for experimentation with market trends and individual styles.

For individuals and small businesses, DTF transfers provide an excellent opportunity to create unique items tailored to specific audiences. Whether you’re designing for local sports teams, schools, or artistic endeavors, DTF transfers make it possible to produce high-quality, personalized items that cater to niche markets, enhancing your branding and customer loyalty.

Frequently Asked Questions

What are DTF transfers and how do they work?

Direct-to-Film (DTF) transfers are a modern printing technique that allows designs to be printed onto a specialized film. The process involves using a DTF printer to print onto the film, which is then coated with an adhesive powder. After applying heat with a heat press, the design adheres to the target fabric, resulting in vibrant and durable prints suitable for various applications.

What equipment do I need for DTF printing?

To start with DTF printing, you’ll need a modified inkjet printer compatible with DTF inks, specialty film for transfers, adhesive powder to bond the design to the fabric, and a heat press machine. These components are essential to achieve high-quality results in your DTF printing projects.

Can beginners use DTF printing techniques effectively?

Yes, DTF printing is accessible for beginners due to its user-friendly processes. By following detailed steps such as design setup, printing, adhesive application, and heat application, even newcomers can create stunning prints. Investing in a comprehensive DTF printing kit can simplify the initial learning curve.

What are some advanced DTF techniques for experienced printers?

Experienced printers can enhance their DTF printing by experimenting with color optimization, layering prints for texture, and troubleshooting common issues. Techniques like printing in layers can create unique effects, while a solid understanding of color profiles can improve the vibrancy and accuracy of prints.

What are common applications for DTF transfers beyond clothing?

DTF transfers are versatile and can be applied to various materials beyond t-shirts, including tote bags, pillows, and custom home décor items. This flexibility allows for creative projects that expand the use of DTF printing techniques into new areas.

What are best practices for successful DTF printing?

To ensure successful DTF printing, pre-press fabrics to eliminate moisture, maintain regular equipment upkeep, and test transfers on different materials. Following manufacturer guidelines closely can help achieve optimal results, while continual innovation in designs will elevate your DTF projects.

| Key Points | |

|---|---|

| What is DTF Printing? | DTF printing allows designs to be printed directly on a film. It involves using a DTF printer to print the design, coating it with adhesive powder, and applying with heat to fabrics. |

| Equipment and Materials Needed | Essential items include a DTF printer, DTF inks, adhesive powder, a heat press machine, and specialty film. |

| Step-by-Step Techniques for Beginners | 1. Design in vector software 2. Print on specialty film 3. Apply adhesive powder 4. Heat transfer to fabric 5. Post-press and cool down. |

| Advanced Techniques for Experts | 1. Color optimization 2. Layering prints 3. Troubleshooting issues 4. Creative uses beyond clothing. |

| Best Practices for Successful DTF Printing | 1. Pre-press fabrics 2. Regular equipment maintenance 3. Test different fabrics 4. Follow manufacturer guidelines 5. Innovate designs. |

Summary

DTF Transfers are reshaping the landscape of custom printing, offering a versatile and user-friendly option for both novices and experienced artisans. This printing technique not only allows for vibrant and durable designs across various fabric types but also encourages creativity through innovative practices and advanced techniques. By understanding the essential equipment, mastering the printing process, and applying best practices, anyone can delve into the exciting world of DTF Transfers and create stunning textile artwork that leaves a lasting impression.