DTF transfers, or Direct-to-Film transfers, are rapidly transforming the landscape of custom apparel printing, providing a modern solution that blends quality with efficiency. This innovative DTF printing technology has gained popularity due to its ability to produce vibrant, high-definition prints on a wide variety of textiles, from cotton to polyester blends. As businesses seek more versatile and cost-effective options, the advent of DTF transfers has proven to be a game-changer, outperforming traditional methods like screen printing in both speed and affordability. With textile printing innovations at the forefront, DTF printing advantages include lower setup costs and quicker turnaround times, making it an appealing choice for small business owners and apparel decorators alike. Understanding these advancements not only benefits industry players but also enhances consumer access to custom, high-quality printed garments.

In the realm of textile printing, Direct-to-Film (DTF) techniques represent a groundbreaking shift towards modern printing methodologies and custom apparel solutions. Often referred to as DTF printing, this approach utilizes advanced technologies that allow for exceptional clarity and durability in printed designs. The remarkable efficiency and cost-effectiveness of DTF transfers make them an attractive option for both large-scale operations and small enterprises looking to enhance their product offerings. As the demand for personalized and unique clothing continues to rise, alternative printing methods like DTF are poised to meet the evolving needs of fashion-conscious consumers and savvy entrepreneurs. Harnessing sophisticated innovations in printing technology not only revolutionizes the customer experience but also sets a new standard in the custom apparel industry.

Understanding DTF Printing Technology

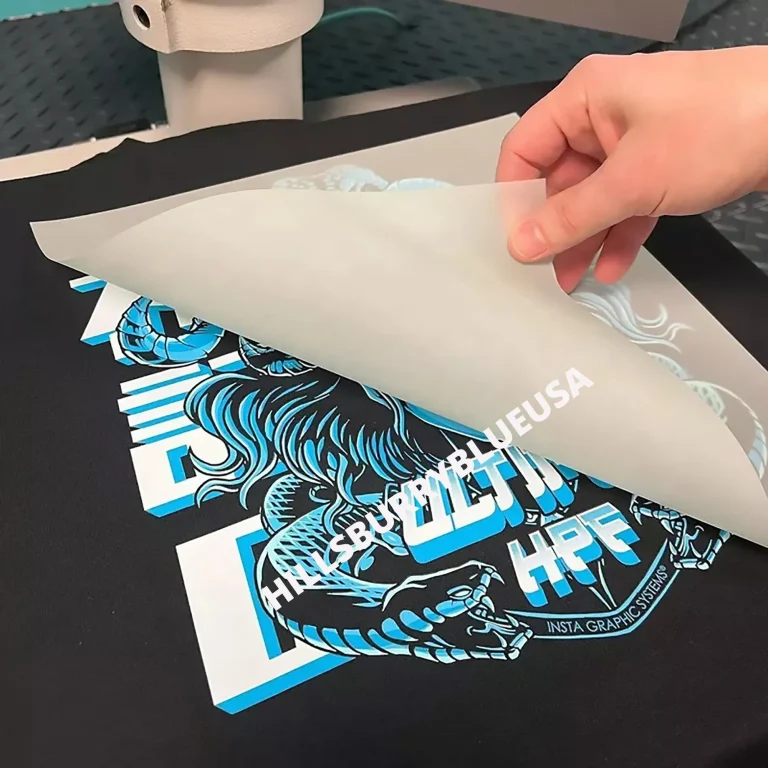

Direct-to-Film (DTF) printing technology represents a revolutionary shift in the textile printing industry. Unlike traditional methods such as screen printing, DTF involves printing designs onto a special film and then transferring them onto garments using heat and pressure. This process allows for much higher flexibility and can accommodate a wide array of fabrics, ranging from soft cotton to synthetic blends. The fine details captured in DTF prints make this technology not only practical for commercial use but also ideal for custom apparel enthusiasts who demand high-quality reproductions of intricate designs.

The versatility of DTF technology is enhanced by its unique ink formulations. These inks are engineered to bond effectively with various textile surfaces, ensuring vibrant colors and outstanding durability. As the demand for personalized and detailed apparel increases, DTF emerges as the go-to solution for businesses looking to innovate in their printing offerings. Additionally, DTF’s ability to produce bold prints that stand out is a key factor attracting consumers who seek distinctive clothing options that reflect their individual style.

The Advantages of DTF Transfers Over Traditional Methods

DTF transfers offer numerous advantages when compared to traditional printing methods, establishing themselves as a favored choice among garment decorators and printing businesses. One of the most notable benefits is the efficiency DTF technology provides. The fast production speeds associated with DTF enable businesses to meet the demands of short-run orders without compromising on quality. This rapid turnaround is particularly advantageous for online retailers and custom apparel shops that must adapt quickly to changing trends and consumer preferences.

Cost-effectiveness is another significant advantage of DTF printing. The lower operational costs associated with DTF transfers—thanks to reduced material expenses and minimized wastage—make it an attractive option for small business owners. As this technology grows more accessible, especially with the advent of affordable printer solutions, more entrepreneurs can harness DTF’s potential to penetrate the market with unique products. The ability to deliver high-quality prints at a lower price point not only enhances profit margins but also ensures that businesses can compete effectively in a saturated market.

Technological Innovations Boosting DTF Printing

Innovations in technology continue to drive advancements in DTF printing capabilities, leading to improved print quality and overall performance. The development of proprietary inks specifically designed for DTF uses has resulted in designs that boast exceptional color vibrancy and resilience. Enhanced formulations ensure that prints withstand frequent washes without fading or losing their integrity, meeting the demands of both consumers and businesses for durable, long-lasting apparel.

Additionally, improvements in DTF printers have been crucial to elevating print standards. With the advent of high-resolution models equipped with refined nozzle technology, businesses can achieve superior precision in their prints. More reliable printers not only reduce the likelihood of errors during production but also contribute to a faster manufacturing process, allowing for higher output and meeting customer demands efficiently. This continuous innovation solidifies DTF printing’s position at the forefront of textile printing technologies.

Market Trends Influencing DTF Printing Growth

Recent market insights indicate that DTF printing technology is experiencing significant growth, driven by evolving consumer preferences for customization and personalization within the apparel market. Reports suggest that the demand for unique fashion items is prompting brands to explore innovative printing solutions like DTF, which offer flexibility and speed in production. This shift toward individual expression in clothing feeds into the broader trend of customization, positioning DTF technology as a key driver in the future of garment printing.

As businesses recognize the potential of DTF printing to fulfill these market demands, investments in this technology are expected to rise. The shift towards affordable yet high-quality printing methods aligns perfectly with modern consumer behavior, where shoppers seek not only uniqueness in products but also the stories behind them. Companies that embrace DTF technology stand to gain a competitive edge by offering tailor-made apparel solutions that resonate with today’s consumers.

Environmental Sustainability and DTF Printing

In light of the increasing focus on sustainability, DTF printing technology proves to be a favorable option when compared to traditional printing methods. DTF transfers generally resulted in lower waste production, which is a significant benefit in an industry known for its environmental impact. The precision of the DTF process minimizes excess material usage, ensuring that businesses can engage in more sustainable practices while still delivering high-quality apparel.

Moreover, advancements in eco-friendly ink formulations used for DTF printing further align this technology with sustainability goals. As environmental concerns rise among consumers, businesses that adopt DTF technology can meet these demands while signaling their commitment to greener methods of production. This alignment with ecological principles not only supports corporate responsibility but can also enhance brand loyalty among environmentally conscious consumers.

Navigating Challenges in DTF Printing Implementation

While the advantages of DTF printing are clear, businesses must also navigate certain challenges when implementing this technology. One significant hurdle is the initial investment required for specialized DTF equipment. For startups and small businesses, the capital outlay for purchasing quality printers and ensuring proper training for staff can be intimidating. Understanding the return on investment potential over time is crucial for these businesses to make informed decisions about adopting DTF printing.

Another challenge lies in achieving print quality that matches or exceeds the softness and feel of legacy printing methods. Many customers prioritize the tactile quality of printed garments, and DTF printing must continually evolve to meet these expectations. As technological advancements continue to unfold, ongoing research, and development are essential to optimize the feel and longevity of DTF prints. By addressing these challenges head-on, businesses can enhance their DTF offerings and provide better products to their customers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing technology that involves printing designs onto a special film, which is then heat-pressed onto fabrics. This method combines the best features of direct-to-garment printing and screen printing, allowing for high-quality custom apparel printing with vibrant colors and durability on various textile surfaces.

What are the advantages of using DTF printing technology?

DTF printing technology offers several advantages, including faster printing speed, lower costs compared to traditional methods, and versatility on different fabric types. DTF transfers allow for intricate designs and vibrant colors while maintaining durability through multiple washes, making them ideal for both small businesses and large-scale production.

How does DTF printing compare to traditional printing methods?

Compared to traditional printing methods like screen printing, DTF printing has a more efficient workflow and requires less setup time. It also produces less waste and accommodates short runs effectively, appealing to businesses wanting custom apparel printing without the high costs typically associated with screen printing or direct-to-garment techniques.

What types of fabrics can be used for DTF transfers?

DTF transfers can be applied to a wide variety of fabrics, including cotton, polyester, blends, and even darker textiles. This flexibility allows for diverse applications in custom apparel printing, making it an attractive option for businesses looking to cater to different customer preferences.

What are the environmental impacts of DTF transfers?

DTF transfers present several environmental benefits over traditional printing methods, such as reduced waste production and the use of eco-friendly inks. As the printing industry increasingly focuses on sustainability, DTF technology is positioned as a greener option that satisfies both quality and eco-conscious production goals.

What challenges do businesses face when adopting DTF printing?

While DTF printing offers many benefits, businesses may encounter challenges such as the need for specialized equipment and ensuring print quality that matches or exceeds legacy printing methods. However, ongoing advancements in DTF printing technology continue to address these issues, enhancing print feel and overall customer satisfaction.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers are revolutionizing printing, especially in textiles, through speed, versatility, and cost-effectiveness. |

| Growing Popularity | DTF transfers are increasingly preferred for high-quality prints on various fabrics, benefiting small businesses and apparel decorators. |

| Efficiency | Quick printing benefits fast-paced businesses and fulfills short runs efficiently. |

| Cost-Effectiveness | Lower material costs than traditional techniques attract budget-conscious entrepreneurs. |

| Technological Advancements | Innovations in inks and printers enhance print quality, durability, and performance. |

| Market Insights | Forecasts indicate significant market growth driven by consumer demand for customization. |

| Environmental Considerations | DTF transfers produce less waste and utilize eco-friendly inks, addressing sustainability concerns. |

| Challenges | The need for specialized equipment and achieving print quality comparable to traditional methods can be obstacles. |

Summary

DTF transfers represent a significant breakthrough in the printing industry, merging efficiency, quality, and affordability. As this innovative technology reshapes the landscape of custom printing, particularly in textiles, businesses and consumers alike are increasingly recognizing its value. With remarkable advancements in printing technology and a growing emphasis on sustainable practices, DTF transfers are setting new benchmarks for the future of apparel production. Stakeholders must keep pace with evolving market dynamics and technological trends, ensuring they harness the myriad benefits of DTF transfers while addressing challenges. This approach will not only foster growth in the printing sector but also promote environmentally conscious practices that resonate with today’s consumer values.