In the booming world of custom apparel, DTF Transfers have emerged as a revolutionary technique, making it easier than ever to achieve high-quality designs. This modern method, known as Direct-to-Film printing, stands out for its ability to produce detailed, vibrant prints that enhance any garment. Unlike traditional heat transfer printing or screen printing, DTF technology allows for unparalleled customization, catering to diverse artistic visions. With the increasing demand for personalized clothing, businesses leveraging DTF transfers are poised to thrive in today’s competitive market. As sustainability becomes a central concern in fashion, many DTF manufacturers are adopting eco-friendly practices, making this innovative printing method not just efficient but also responsible.

Introducing an innovative approach to garment decoration, Direct-to-Film transfers, often referred to as DTF printing, is transforming how custom apparel is created and produced. This cutting-edge technique leverages heat transfer technology to transfer intricate designs onto various fabrics, making it a favorite among designers and businesses alike. DTF printing provides a sustainable solution that doesn’t compromise on quality, allowing for personalized pieces that reflect individual styles. The versatility of this method is evident as it adapts easily to various materials, from cotton to polyester blends. With DTF transfers, the future of custom clothing is not only bright but also responsible, appealing to a growing audience that values both creativity and sustainability.

Understanding the Advantages of DTF Transfers

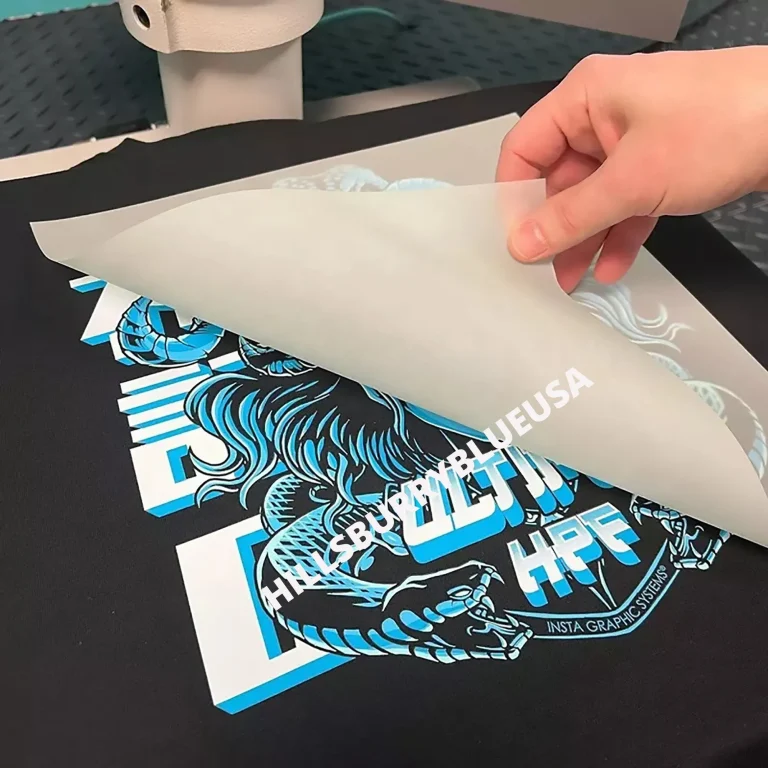

DTF Transfers, or Direct-to-Film transfers, represent a significant leap forward in printing technology for custom apparel. This method involves printing designs onto a heat-resistant film, which is then applied to garments using a heat press. One of the major advantages of DTF printing is the vibrancy of colors it produces—this technique allows for an impressive range of color depth and detail that surpasses traditional methods such as screen printing. The overall finish not only captures intricate designs but also provides a sleek, modern look that appeals to contemporary consumers.

Moreover, DTF Transfers ensure versatility; they can be printed on a variety of fabrics, including cotton, polyester, and blends. This adaptability means businesses can cater to diverse customer needs without being limited to specific materials. Through DTF technology, designers can produce high-quality prints with fewer restrictions on fabric choice, which significantly enhances their product offerings in the fast-paced custom apparel market.

The Cost-Effectiveness of DTF Printing

In the competitive world of custom apparel, managing expenses is crucial for small businesses and startups. DTF printing offers a remarkably cost-effective solution compared to other printing methods. Given that this technique eliminates the need for large setups and allows for on-demand production, businesses can significantly decrease upfront investment costs. This makes DTF Transfers an attractive option, particularly for those looking to minimize financial barriers while still producing high-quality custom designs.

Additionally, the reduced material waste associated with DTF printing not only contributes to lower costs but also aligns with sustainable business practices. As more companies seek to establish themselves as environmentally conscious, the ability to produce printed items without excessive materials boosts both profitability and brand reputation among eco-sensitive consumers.

Customization and Market Demand for DTF Transfers

As consumer preferences evolve, the demand for unique and personalized apparel has surged. DTF Transfers cater perfectly to this trend by enabling businesses to offer customized prints in low quantities without compromising on quality. As customers increasingly desire garments that reflect their individuality, the ability to leverage DTF technology for small batch runs becomes a strategic advantage for retailers in the custom apparel landscape.

Personalization not only enhances customer satisfaction but also fosters brand loyalty. When customers can access unique designs tailored to their personal tastes, they are more likely to return for future purchases. Thus, DTF Transfers not only fulfill a market demand but also serve as a pathway for businesses to cultivate a loyal customer base through distinctive, personalized offerings.

The Role of Sustainability in DTF Printing

Sustainability has become a cornerstone of consumer decision-making, especially in the fashion and apparel sector. DTF printing technologies have arisen to meet this demand, as many manufacturers are committed to using eco-friendly inks and reducing waste in their production processes. By opting for DTF Transfers, businesses not only benefit from high-quality prints but also engage with a broader demographic that prioritizes environmental considerations in their purchasing decisions.

The incorporation of sustainable practices within DTF printing not only reflects positively on a brand’s image but can also differentiate it within a saturated market. Consumers today are more conscientious and are increasingly drawn to brands that showcase a commitment to sustainable methods, thus reinforcing the importance of adopting eco-friendly practices in the custom apparel industry.

Mastering DTF Printing: Resources and Learning

With the growing interest in DTF Transfers, numerous resources are available for those looking to master this innovative printing method. Online tutorials, webinars, and workshops provide invaluable insights into everything from setting up equipment to optimizing print quality. Platforms such as YouTube feature content from experienced professionals who share tips and techniques, making it easier for newcomers to grasp the nuances of DTF printing effectively.

Additionally, industry blogs and forums often discuss the latest trends, challenges, and solutions in DTF printing. Engaging with these resources not only accelerates the learning process but also connects businesses with a community of like-minded entrepreneurs who share knowledge and support. Such collaboration can be instrumental in overcoming common obstacles faced in the transition to this form of printing.

Addressing the Challenges of DTF Transfers

Despite their many advantages, DTF Transfers do present some challenges that businesses must navigate. One of the biggest hurdles is the initial investment in specialized equipment—DTF printers and heat presses can be costly, posing a challenge for startups operating on tight budgets. It’s crucial for businesses to plan carefully and consider these upfront costs against long-term gains in quality and efficiency.

Moreover, the quality of the adhesive used in DTF printing can vary, affecting the durability and longevity of prints. To mitigate these risks, businesses should work closely with reliable suppliers and conduct tests to ensure that they are using the highest quality materials. Addressing these challenges proactively allows companies to thrive while reaping the benefits of this cutting-edge printing technology.

Frequently Asked Questions

What are DTF transfers in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing method where designs are printed onto a special film and then heat-pressed onto fabric. This technique is gaining popularity for its ability to produce vibrant colors, handle intricate details, and adapt to various materials such as cotton and polyester blends.

Why should businesses choose DTF printing for custom apparel?

Businesses should consider DTF printing due to its cost-effectiveness, especially for small operations. DTF transfers require minimal initial setup, allowing businesses to print on-demand. This makes it an ideal choice for those entering the custom apparel market, providing high-quality prints without significant upfront investments.

How does DTF transfers compare to traditional heat transfer printing?

DTF transfers offer several advantages over traditional heat transfer printing, including better color vibrancy and detail retention. Unlike traditional methods, DTF printing uses eco-friendly inks and has a more extensive material compatibility, making it a more versatile and sustainable choice for custom apparel production.

What are the advantages of using DTF printing technology?

The advantages of DTF printing technology include superior image quality, vibrant colors, and the ability to produce complex designs on various fabrics. Furthermore, DTF transfers support low-quantity printing, catering to the growing demand for personalized custom apparel while being a cost-effective solution for other businesses.

Are DTF transfers a sustainable printing option for custom apparel?

Yes, DTF transfers can be a sustainable printing option as many manufacturers use eco-friendly inks and techniques that minimize waste. This aligns with the increasing consumer demand for environmentally conscious practices in the apparel industry, making DTF printing a responsible choice for custom apparel providers.

What challenges might businesses face with DTF printing?

While DTF printing presents numerous benefits, businesses might face challenges such as initial equipment investment for DTF printers and heat presses. Additionally, the quality of adhesives used can vary, impacting the longevity of prints. It’s essential to work with reliable suppliers and conduct material tests for optimal results.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | Direct-to-Film (DTF) transfers involve printing designs onto special film which are then transferred to fabric using heat. This method supports vibrant colors, intricate detailing, and versatility over various materials. |

| Popularity Reasons | 1. Cost-Effectiveness for businesses. 2. Personalization demand in retail. 3. Quality improvements in DTF technology. |

| Sustainability in DTF Printing | Eco-friendly inks and reduced waste are becoming common in DTF printing, appealing to environmentally conscious consumers. |

| Challenges | Equipment investment is needed for specific DTF printers and quality of adhesive can vary, impacting longevity. |

Summary

DTF Transfers are transforming the custom apparel market as a sophisticated printing solution that offers vibrant colors and high detail at a cost-effective price. By employing a unique method of transferring prints from a film to fabric, DTF technology meets the high demand for personalization in today’s consumer market. The recent advancements in eco-friendly options further boost the appeal of DTF Transfers, aligning printing practices with sustainability efforts. Businesses and hobbyists alike can benefit from this innovative approach, ensuring that their creations stand out with quality and individuality.