DTF transfers, or Direct to Film transfers, are revolutionizing the world of custom apparel by providing a seamless method to print vibrant designs on various fabrics. With the ability to produce high-quality, durable artwork, many businesses and crafting enthusiasts alike are eager to delve into DTF printing techniques. Our comprehensive DTF printing guide will walk you through the essential steps of using this innovative transfer method, from setting up the right equipment to perfecting your designs. Discover the numerous benefits of DTF printing, such as its versatility and compatibility with a wide range of materials, as well as insights about DTF inks and films that enhance every project. This introduction not only sets the stage for mastering DTF transfers but also highlights the creative potential that awaits in the custom apparel market.

In the realm of textile printing, the advent of Direct to Film technology has significantly simplified the design application process for garments. Often referred to as DTF printing, this technique allows for exceptional image quality and a wide range of fabric compatibility, establishing it as a favored choice among fabric decorators and hobbyists alike. By utilizing specialized films and inks, creators can achieve stunning, long-lasting prints that elevate custom apparel offerings. Whether you’re interested in the intricacies of DTF inks and films or simply seeking guidance on how to use DTF transfers effectively, understanding this process can greatly enhance your capabilities. As you explore the various aspects of DTF transfers, you’ll uncover benefits that extend beyond just aesthetics, further enriching your textile printing journey.

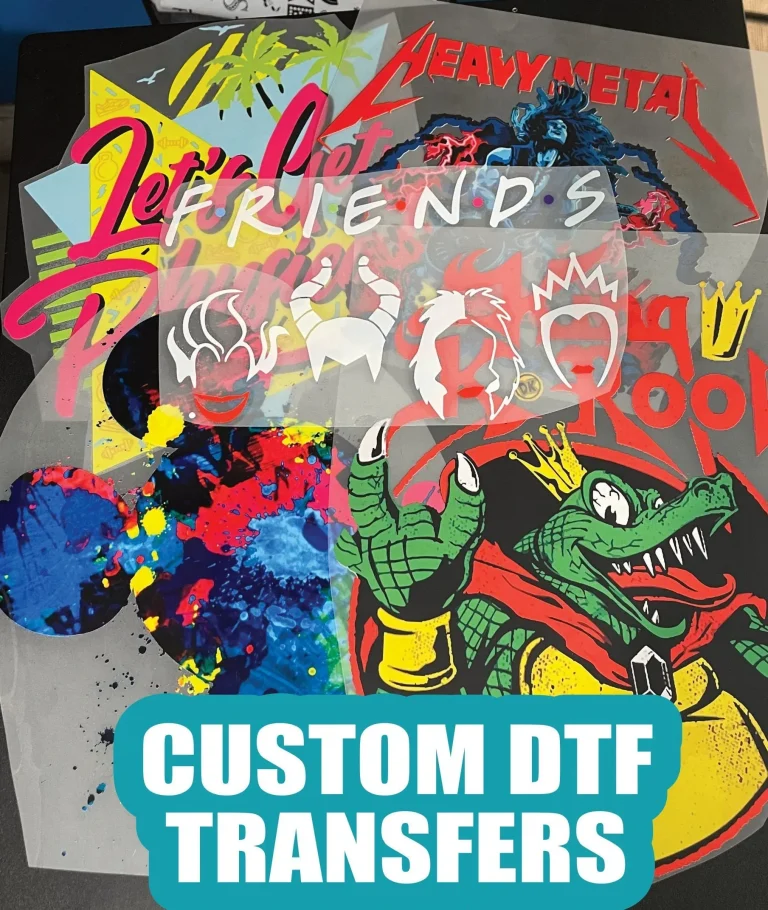

Understanding the Basics of DTF Transfers

DTF transfers are revolutionizing the way custom apparel is made. This method utilizes a film to apply vibrant designs directly onto the fabric, offering unmatched clarity and resilience compared to traditional printing methods. The versatility of DTF transfers allows both beginners and experienced printers to produce stunning designs on various textiles, including cotton, polyester, and blends, making it an ideal choice for diverse apparel projects.

The process involves printing your design onto a special transfer film using DTF inks, which are specially formulated to retain their vibrancy even after washing. This mechanism of using heat to bond the ink to the fabric results in durable apparel that can withstand the test of time. Therefore, understanding the foundational aspects of DTF transfers is crucial for anyone looking to enter the custom printing arena.

Essential Equipment for DTF Printing Success

To achieve the best results with DTF transfers, having the right equipment is paramount. You’ll need a quality DTF printer specially designed to handle DTF inks, which are distinct from standard inkjet inks due to their unique formulation. A reliable heat press is also crucial, as it applies the necessary temperature and pressure to ensure the transfer sticks effectively to the fabric.

In addition, investing in high-quality DTF film is essential. The film needs to be compatible with both the printer and the adhesive powder used. Therefore, choosing reputable suppliers for your DTF films and inks will differentiate your outcomes, allowing for not only a vibrant finish but also a longer-lasting print that fulfills customer satisfaction.

Step-by-Step Guide to Preparing DTF Transfers

Preparing your designs for DTF transfers involves several critical steps to ensure success. Utilizing design software, you first create or modify your artwork to fit the desired dimensions. This includes ensuring the design is mirrored before printing, a crucial step that guarantees the image appears correctly on the final product.

The next step is to load the DTF film into your printer and select the appropriate settings for optimal print quality. This includes adjusting the ink saturation and ensuring that you’re using the correct DTF inks, which can substantially influence the final vibrancy of the print. Following this preparation meticulously sets the stage for flawless transfers.

Applying Adhesives for Optimal DTF Transfers

After printing your design onto the DTF film, the application of adhesive powder is a vital step. As soon as the ink is printed, evenly sprinkle the adhesive powder over the wet design. This process must be done swiftly to ensure that the powder adheres properly to the printed areas, preparing it for the heat application process.

Following the sprinkling of adhesive powder, curing it is critical. This is usually accomplished by applying heat at a specific temperature for a predetermined amount of time. This heating process ensures that the adhesive bonds effectively with the ink and film, laying the groundwork for the final transfer to fabric.

Heat Transfer Techniques for DTF Printing

The heat transfer phase is where DTF printing comes to life. Preheating your heat press to the specified temperature is essential to ensure proper adhesion of the DTF transfer to the garment. Depending on the DTF film used, the heat and pressure settings may vary slightly, so always refer to the manufacturer’s guidelines for best results.

Once the press is ready, position the DTF film on the garment carefully. Press down with even pressure and for the recommended time. This step not only transfers the design but also sets the adhesive, ensuring a long-lasting bond that brings your vibrant designs to life on fabric.

Advantages of Using DTF Transfers for Custom Apparel

DTF transfers offer several advantages over traditional printing methods, making them a preferred choice for many custom apparel vendors. One significant benefit is the ability to achieve high-resolution and detailed designs, which are crucial for branding and personalization in custom apparel. Unlike screen printing, which can limit color choices and detail precision, DTF printing allows for a wider color spectrum and intricate details.

Moreover, DTF transfers provide excellent durability and washability, ensuring that garments maintain their aesthetics even after multiple wash cycles. This reliability is a considerable selling point for businesses looking to produce high-quality apparel that meets customer expectations for longevity and performance.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing technique that allows designers to print high-quality images directly onto special DTF film using DTF inks. After printing, adhesive powder is applied to the wet ink, and heat is used to cure the powder. When transferred to garments using a heat press, this method ensures vibrant, durable designs on various fabric types.

What equipment do I need for DTF printing?

To successfully create DTF transfers, you need a DTF printer compatible with DTF inks, a heat press for applying the transfers, and DTF film along with adhesive powder. These tools are essential for achieving high-quality prints and ensuring that designs adhere well to the fabric.

What are the benefits of DTF printing compared to other printing methods?

DTF printing offers several benefits, including its versatility to print on multiple fabric types, vibrant color reproduction, and strong durability. Unlike traditional methods, DTF transfers can effectively create detailed designs that withstand washing and wear, making them ideal for custom apparel production.

How do I prepare designs for DTF transfers?

To prepare designs for DTF transfers, use graphic design software to create or edit your artwork. Be sure to mirror the design before printing, as this is crucial for proper application on your garments. Additionally, ensuring high-resolution images will contribute to the clarity of the final print.

Can I use DTF transfers on different fabric types?

Yes, DTF transfers are highly versatile and can be applied to various fabric types, including cotton, polyester blends, and other materials. This adaptability makes DTF printing a popular choice against traditional methods, which can be limited by fabric color and type.

What are the recent innovations in DTF transfer techniques?

Recent innovations in DTF transfer techniques include the incorporation of eco-friendly DTF inks and materials, as well as hybrid methods that combine DTF printing with sublimation printing. These advancements are aimed at improving fabric compatibility and addressing consumer demands for environmentally sustainable practices in custom apparel.

| Step | Description |

|---|---|

| 1. Equipment Needed | Essential tools include DTF printer, heat press, DTF film, and adhesive powder. |

| 2. Design Preparation | Create and mirror designs using graphic design software before printing. |

| 3. Printing Your Design | Load DTF film into the printer and use DTF inks for high-quality prints. |

| 4. Applying the Adhesive Powder | Sprinkle adhesive powder on wet printed design and cure it with heat. |

| 5. Heat Transfer Process | Preheat heat press and transfer design to garment, then peel film after cooling. |

| 6. Finishing Touches | Repress design and allow curing before final use. |

Summary

DTF transfers have revolutionized the world of custom apparel, allowing creators to print vivid designs on various fabrics with ease. Understanding the complete process—from the necessary equipment to the heat transfer technique—enables manufacturers and hobbyists alike to produce high-quality prints that stand the test of time. By optimizing your approach and staying current with the latest advancements in DTF technology, you can enhance your skills and meet the evolving demands of this dynamic industry. As the custom apparel landscape continues to grow, mastering DTF transfers will position you for success.