DTF Transfers, or Direct-to-Film transfers, have revolutionized the world of custom apparel printing by offering a modern solution that outperforms traditional methods like screen printing and direct-to-garment (DTG) printing. This innovative technique allows for high-quality designs to be printed on specialized transfer films, which can then be applied to a variety of fabrics with impressive results. Unlike screen printing, which can be limited by color and design complexity, DTF printing excels with vibrant colors and intricate details. As businesses increasingly seek flexibility and efficiency in their production processes, DTF Transfers are quickly becoming the preferred choice for many. In this guide, we will explore the benefits of DTF compared to other printing methods, ensuring you make informed decisions for your apparel needs.

In the realm of apparel decoration, DTF printing, also known as Direct-to-Film printing, represents an advanced approach that is gaining traction among businesses seeking efficient solutions for custom designs. This process differentiates itself from conventional methods like screen printing and DTG, allowing for a broader range of applications and creative possibilities. With its quick application and capability to produce vibrant, detailed graphics on various materials, it’s no wonder that DTF has emerged as a strong alternative for those in the custom apparel industry. As the market continues to evolve, understanding these alternative printing techniques is essential for professionals looking to streamline their operations and enhance product offerings.

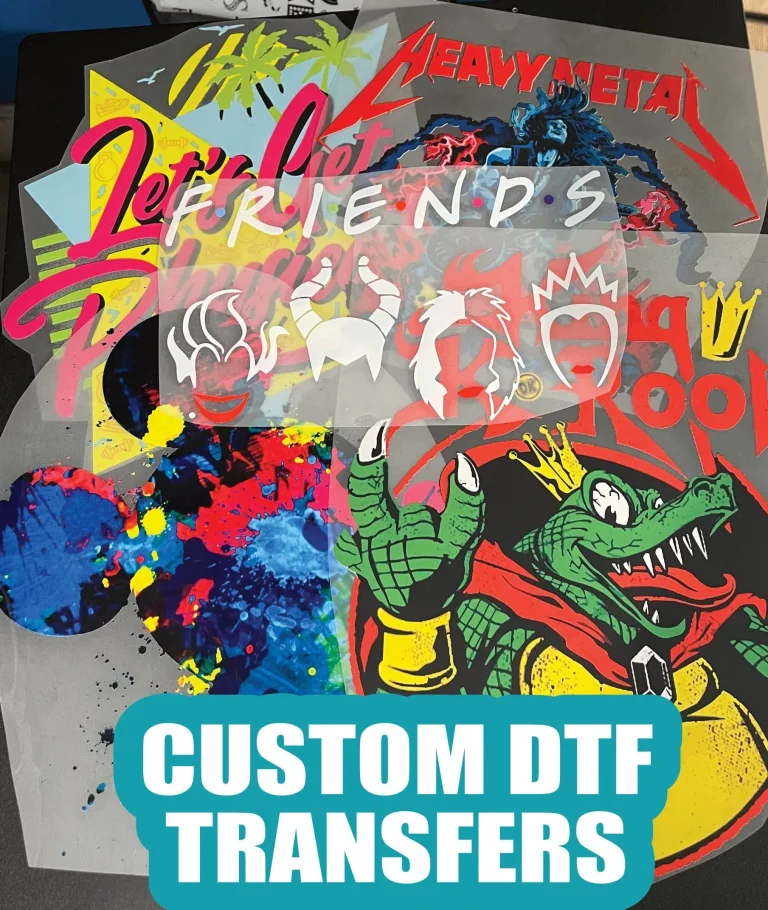

The Rise of DTF Transfers in Custom Apparel Printing

DTF transfers are rapidly becoming a popular choice in the custom apparel printing industry, largely due to their flexibility and ease of use. Unlike traditional methods like screen printing, which can be cumbersome for small orders, DTF printing allows businesses to produce high-quality designs without significant setup costs. This makes it an ideal solution for entrepreneurs who are looking to produce custom designs efficiently and at a lower price point. As more businesses recognize the efficiency of DTF, the method is gaining traction and transforming how custom apparel is produced.

The rise of DTF transfers can also be attributed to technological advancements that have made the process more accessible. Companies like Sam’s DTF Transfers have become leaders in offering DTF options that cater to the growing demand for unique and high-quality prints. The ability to print on various fabric types and achieve intricate detail makes DTF a preferred option for both small and large businesses aiming to provide customized products that stand out in a competitive market.

Comparing DTF Transfers and Screen Printing

When evaluating DTF transfers against screen printing, significant differences emerge in terms of application and design flexibility. Screen printing often follows strict guidelines regarding color limitations, making it challenging to execute complex designs. On the other hand, DTF printing allows for a greater color range and intricate designs, which is particularly beneficial for graphic-heavy apparel. This flexibility enables brands to explore more creative avenues, thus broadening their market appeal.

Additionally, the durability of DTF transfers offers a compelling advantage over screen printing. While screen printing is known for longevity, DTF technology has made great strides in producing prints that retain vibrant colors even after multiple washes. This durability ensures that garments look fresh for longer, leading to increased customer satisfaction and repeat business, essential for any custom apparel brand.

Cost-Effectiveness of DTF Transfers Versus Other Methods

One significant concern for businesses is balancing quality with cost-efficiency. DTF transfers shine in this area by offering lower initial setup costs compared to both screen printing and direct-to-garment printing. For companies focusing on small runs or unique pieces, DTF represents a cost-effective option that allows for profit margins without the burden of expensive equipment or setup fees associated with traditional printing methods.

Moreover, as the demand for custom designs grows, DTF’s affordability makes it possible for startups and smaller businesses to compete with established brands. The overall reduction in cost encourages creativity, allowing entrepreneurs to explore a wide range of designs and colors without breaking the bank. This financial advantage is crucial when trying to establish a foothold in the competitive custom apparel market.

Embracing Technology: Future of DTF Printing

Technological advancements continue to reshape the landscape of DTF printing, highlighting its potential in the custom apparel sector. Innovations in printing technology have led to faster speeds, better quality outputs, and improvements in the types of materials that can be used. Businesses can now create vibrant, intricate designs that were previously difficult to achieve with methods like screen printing and direct-to-garment printing.

As DTF technology continues to evolve, we can anticipate even greater efficiencies in production and a wider array of applications for various fabrics. The introduction of enhanced inks and printers specifically designed for DTF transfers paves the way for high-quality prints that meet consumer demands. This trajectory of innovation positions DTF printing as a frontrunner among printing methods, solidifying its status in the future of the custom apparel industry.

Getting Started: Transitioning to DTF Printing

Transitioning to DTF printing requires a keen understanding of the necessary equipment and processes. Companies aiming to integrate DTF should first assess their current capabilities and determine the types of designs they wish to produce. Investing in a compatible printer, along with high-quality transfer films and specialty inks, is essential to ensure optimal results. Brands like DTFPrinter provide valuable resources and guidance for newcomers looking to make the switch.

Moreover, training staff on DTF processes can enhance the quality of output and streamline production. When employees are well-versed in the intricacies of DTF printing, businesses can ensure consistency and quality in their products. By adopting these fundamental approaches, companies can smoothly transition to DTF printing and leverage its benefits for their custom apparel offerings.

Customer Trends: Understanding DTF Printing Demand

Monitoring customer trends is crucial in the custom apparel market, and DTF printing is steadily gaining traction due to consumers’ growing appetite for unique and personalized products. As shoppers increasingly seek out custom designs, businesses that offer DTF printing are well-placed to capitalize on this demand. The technology allows for rapid customization of apparel, offering consumers diverse options that would fulfill their individual tastes.

Social media platforms have amplified the visibility of DTF printing, with many users showcasing their unique custom apparel creations. This surge in visibility influences consumer buying decisions, reinforcing the importance of providing high-quality, customizable options. As businesses adapt to these trends, they can ensure their offerings remain relevant and appealing in a fast-paced market.

Frequently Asked Questions

What are DTF transfers in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing method that involves printing vibrant designs onto a special film before transferring them to fabric. This technique allows for detailed graphics to adhere to various materials, making it a popular choice in custom apparel printing.

How do DTF transfers compare to screen printing?

DTF transfers offer greater flexibility than screen printing, accommodating intricate designs with multiple colors and printing on various fabric types like cotton and polyester. While screen printing boasts durability, DTF technology has advanced significantly to ensure long-lasting, high-quality prints.

Are DTF transfers more cost-effective for small runs?

Yes, DTF transfers are generally more cost-effective for small runs due to their lower initial setup costs compared to screen printing. This makes DTF an ideal choice for businesses or individuals needing unique custom pieces without making hefty investments.

Can DTF transfers match the quality of direct-to-garment (DTG) printing?

While DTG printing is known for producing high-quality prints directly on fabric, DTF transfers can result in vibrant and detailed designs that adhere well to a variety of fabric types, making them a versatile alternative to DTG, especially for polyester blends.

What technological advancements have improved DTF printing?

Recent technological advancements in DTF printing have enhanced production speed and print quality, allowing for quicker turnaround and less extensive preparation compared to traditional methods like screen printing and DTG, making DTF an efficient choice for custom designs.

What types of fabric can DTF transfers be used on?

DTF transfers are versatile and can be applied to various fabrics, including cotton, polyester, and their blends. This wide range of compatibility makes DTF an excellent option for different types of custom apparel printing projects.

| Aspect | DTF Transfers | Screen Printing | DTG Printing |

|---|---|---|---|

| Flexibility and Application | Allows for vibrant colors and intricate details. Can print on various fabrics. | Limited by simultaneous color usage, restricting design complexity. | Versatile but primarily aimed at cotton fabric. |

| Durability | Can withstand multiple washes, retaining quality and detail. | Lasts over 50 washes without significant fading. | Quality adherence to fabric varies with conditions. |

| Cost-Effectiveness | Lower setup costs, ideal for small runs and custom pieces. | More economical for larger orders due to setup efficiencies. | Higher initial investment with longer setup time. |

| Technological Advancements | Continuously evolving for better speed and quality outputs. | Generally requires more extensive preparation times. | Requires longer setup times for varying designs. |

Summary

DTF Transfers have emerged as a powerful and innovative technique for custom apparel printing. Offering a balance of flexibility, vibrant colors, and cost-effectiveness, DTF Transfers stand out against traditional methods such as screen and direct-to-garment (DTG) printing. As industries evolve, DTF Transfers prove to be particularly advantageous for smaller businesses requiring quick solutions and high-quality results. Companies like Sam’s DTF Transfers are enhancing the market by making these solutions more accessible and providing timely services. With continued technological advancements, DTF Transfers are likely to become the go-to method for many in the custom clothing space.