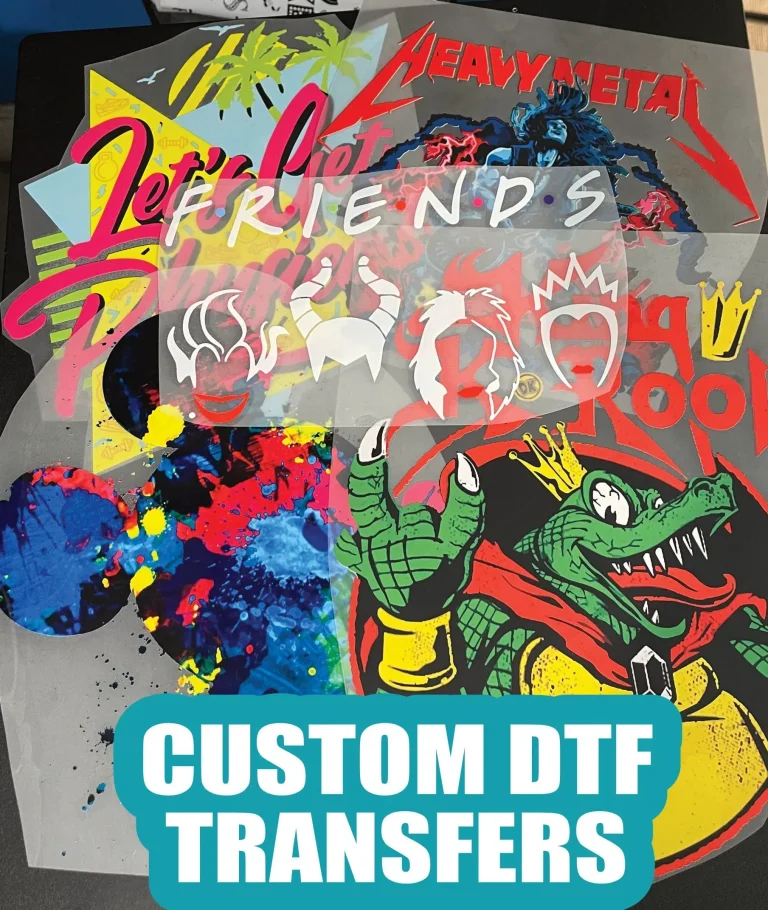

In the ever-evolving landscape of custom apparel, DTF transfers have risen to prominence as a game-changing printing method. Harnessing the power of direct-to-film technology, DTF printing not only allows for striking and intricate custom designs but also caters to various fabric types, ensuring versatile application across different apparel. From t-shirts to hoodies, DTF transfers provide unparalleled quality in heat transfer printing, allowing vibrant and durable images that stand the test of time. As trends in apparel sizing continue to shift, understanding the nuances of DTF transfers by size is essential for achieving the best design impact. This guide will delve into the intricacies of DTF transfers, offering insights into how they can elevate your custom apparel to new heights.

Also known as Direct to Film printing, the DTF transfer method represents a cutting-edge approach in the customization of clothing and accessories. This printing technique is gaining traction among apparel creators due to its flexibility and the high-definition output it delivers on a variety of fabrics. Whether you’re looking to enhance your brand with unique shirts or develop an entire line of apparel featuring custom graphics, understanding this innovative technology is crucial. As more artisans and businesses rely on heat transfer solutions, DTF printing stands as a standout choice among alternative printing methods. As we explore this topic further, you’ll discover how effective sizing and design can transform your custom apparel offerings.

What You Need to Know About DTF Printing

DTF printing, or Direct to Film printing, is a cutting-edge method that allows for stunningly detailed and vibrant designs to be transferred onto a wide variety of fabrics. Unlike traditional heat transfer methods, DTF technology involves printing an image onto a special film, applying a unique adhesive powder, and then using heat to bond the design to the fabric. This innovative approach not only enhances visual appeal but also enables the use of intricate designs that can withstand the test of time through multiple washes. Whether you’re looking to create custom t-shirts, hoodies, or any other apparel, DTF printing can elevate your designs to new heights.

An important advantage of DTF vs. traditional printing techniques is the seamless versatility it offers. This method allows for the creation of custom apparel across diverse fabric types, including cotton, polyester, and even blends. The flexibility in printing options makes it easier to accommodate wearers’ needs while attracting a wider audience. DTF printing is transforming the apparel industry by promoting trends geared towards personalization and customization that resonate well with consumers seeking unique styles.

With the rise of e-commerce, businesses have increasingly turned to DTF printing as a pivotal option in their custom apparel offerings. Not only does it accommodate low-volume orders efficiently, but it also meets customer demands for tailored pieces, making it an appealing choice for retailers.

Lastly, understanding the mechanics of DTF printing is essential for any designer or business owner. Mastery of this process requires attention to printer specifications, heat settings, and substrate considerations. By familiarizing oneself with these factors, anyone can optimize their results and create high-quality custom applications.

Maximizing the Benefits of DTF Transfers

DTF transfers present vast advantages, especially when it comes to durability and resilience in the competitive world of custom apparel. Once applied correctly, these transfers are robust and can withstand numerous washes without losing vibrancy or quality. This reliability ensures that your customers remain satisfied with the longevity of their customized clothing, thus enhancing brand loyalty. Furthermore, unlike other methods that may risk cracking or fading over time, DTF transfers provide a softer finish that maintains all-day comfort while retaining an appealing aesthetic.

Additionally, DTF transfers thrive in situations demanding quick turnaround times. Businesses can efficiently produce high-quality designs on a small or large scale, making this process ideal for on-demand printing and bulk orders. This agility not only helps in keeping production costs low but also meets the ever-evolving consumer preferences for personalized items. The ability to execute custom designs rapidly while prioritizing quality makes DTF the perfect choice for novice entrepreneurs and established brands alike.

Custom apparel trendsetters realize that the key to standing out in a saturated market is through distinctive designs that resonate with the audience. DTF transfer technology fosters creative freedom, thus making it easier to bring unique ideas to life. Innovators can harness the vast capabilities of custom designs to tell stories through garments, enhancing the emotional connection consumers feel toward the brand.

Ultimately, capitalizing on the benefits of DTF transfers leads to a fruitful custom apparel business. A deep understanding of consumer demand for innovative and customized options ensures that brands can adjust their strategies accordingly, promoting growth and success in the market.

Expert Tips on DTF Transfer Sizing

Getting the sizing of DTF transfers right is critical in determining the success of your custom apparel designs. Each type of garment—whether a fitted t-shirt or an oversized hoodie—requires different size specifications. Artwork that is too small can appear lost or insignificant, while overly large designs may overwhelm the garment and distract from its intended look. A common guideline that designers should follow for t-shirts is to maintain the width of front designs within 8-12 inches, while larger apparel may gracefully accommodate designs spanning 12-20 inches.

Moreover, a well-planned layout can work wonders in improving the overall aesthetic of the apparel. Positioning guidelines suggest that logos should sit approximately 3-4 inches from the neckline, facilitating a cohesive appearance. These sizing rules create a balanced look, making the garment visually appealing while also ensuring brand visibility. Consider investing time in mock-ups to visualize the final product and adjust the scale until you achieve the desired effect.

Another vital aspect is to take into account various body sizes and different fits of your garments. Properly sizing artwork not only influences how it looks on the shirts but also impacts how customers feel when wearing them. It’s essential to consider the dimensions of your target audience and ensure your designs cater to a wide demographic. The right sizing can enhance functionality and style, making your custom apparel choices even more desirable.

Lastly, testing your designs on actual garments before final production is a game-changer. Running sample prints allows you to gauge how well the sizing works on different apparel styles. By implementing good sizing practices, businesses can enhance customer satisfaction, which ultimately translates into repeat purchases and successful brand growth.

Current DTF Transfer Trends to Watch

In 2025, the DTF transfer landscape is witnessing several trends that merit attention from custom apparel enthusiasts and industry professionals alike. One notable shift is the increasing demand for environmentally-friendly inks and materials in the DTF printing process. As sustainability becomes a major concern for consumers, businesses are pivoting towards eco-conscious options that not only lessen environmental impact but also appeal to conscious buyers. Utilizing water-based inks and biodegradable transfer films allows brands to offer products that align with evolving market values.

In addition to environmental considerations, personalization is taking center stage. Customers are looking for unique apparel that reflects their individual personalities. Advances in DTF printing technology facilitate an explosion of creativity, allowing businesses to provide a vast array of custom designs tailored to specific customer preferences. From personalized graphics to unique color combinations, the trends in DTF printing are paving the way for brands to forge closer connections with their clientele.

Another trend to keep an eye on is the integration of technology to enhance the DTF workflow. As artificial intelligence and automation enter the custom apparel scene, more companies are adopting advanced solutions to streamline production processes, manage inventory, and accelerate order fulfillment times. This technological shift promises to redefine efficiency while delivering consistent, high-quality products within short turnaround times.

Finally, we can expect the market for DTF transfers to expand internationally. With the global rise in e-commerce, businesses are virtually reaching new audiences, allowing them to offer their custom designs to customers worldwide. This globalization of DTF technology presents exciting opportunities for innovative brands to establish their footprint across diverse markets.

Essential DTF Transfer Setup and Printing Guidelines

Setting up your DTF transfer process effectively is vital for achieving high-quality outputs in your custom apparel designs. To ensure precision, the printer should be correctly calibrated according to the manufacturer’s specifications, covering aspects like temperature, print speed, and ink usage. Addressing these technical details can drastically improve the quality of the prints while preventing costly mistakes during production.

Moreover, understanding print resolution and color management is essential for producing vibrant designs that capture attention. High-resolution images not only create sharper and clearer visuals but also reflect design vibrancy accurately on fabric. It’s crucial to configure color profiles that align with both the printing equipment and desired output to ensure a seamless translation from digital art to finished product.

Implementing robust quality control measures can further enhance the effectiveness of your DTF printing process. Always conduct test prints before rolling out large orders; this allows you to verify that the colors and details meet your expectations. Incorporating routine quality checks helps prevent reprints, saving both time and production costs while ensuring that each item meets a high standard that satisfies customers.

Efforts made in establishing effective production protocols can yield long-term benefits for your custom apparel business. When setups are optimized, and quality is prioritized, it becomes much easier to build a reputation for excellence in DTF transfers, leading to customer trust and finally, brand loyalty.

Exploring Marketplace Insights for DTF Transfers

As the custom apparel marketplace continues to evolve, DTF transfers are emerging as a preferred choice among businesses seeking innovative production solutions. The flexibility of DTF technology allows for low-volume printing, which caters to the growing trend of personalized apparel tailored to individual preferences. Business owners need to recognize this shift in the market and align their strategies towards offering unique tailored solutions that resonate with customers, whether they sell through online platforms or brick-and-mortar stores.

Moreover, the increasing demand for DTF transfers in the custom apparel market opens up new avenues for collaboration with reliable suppliers. Partnering with established vendors that provide high-quality transfer films and inks can enhance product output significantly. Companies should prioritize building relationships with suppliers who share their commitment to quality and sustainability, ensuring that they maintain a competitive edge in this fast-paced environment.

Additionally, businesses must stay informed about customer preferences in order to cultivate a strong brand presence. Keeping track of aesthetic trends, popular themes, and consumer interests allows brands to refine their product offerings. Smarter inventory management systems that incorporate consumer behavior data can empower businesses to make informed decisions from design inception to final distribution.

In summary, channeling insights from the marketplace will better position brands to navigate the complexities of the custom apparel landscape. Understanding the dynamics of DTF transfers, coupled with proactive strategies, equips businesses to thrive in an increasingly demanding environment while meeting the diverse expectations of their customers.

Frequently Asked Questions

What are DTF transfers and how do they work for custom apparel?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film which can then be applied to various fabric types using heat. This method is suitable for custom apparel, allowing for vibrant colors and intricate details that stand out on garments like t-shirts and hoodies.

How do I choose the right size for DTF transfers for my custom designs?

Choosing the correct size for DTF transfers is crucial for visibility and design integrity. Small transfers work well for logos (3-5 inches wide), medium transfers for front designs (6-10 inches), and large transfers for back graphics (up to 12-16 inches). Ensure the size fits the garment area appropriately.

What advantages do DTF transfers have over other printing methods in custom apparel?

DTF transfers offer several advantages including high detail, vibrant color quality, and versatility across different fabric types. They are also known for their durability and soft texture, making them ideal for custom apparel that withstands multiple washes without losing quality.

What are common placement rules for DTF transfers on apparel?

For effective placement of DTF transfers on apparel, ensure that center logos are about 3-4 inches from the neckline. For t-shirts, aim for a width of 8-12 inches for front designs, while larger garments like hoodies can accommodate prints ranging from 12-20 inches.

How does apparel sizing affect DTF transfer applications?

Understanding apparel sizing is essential when applying DTF transfers, as the size and fit of the garment will determine the appropriate dimensions for the transfer. Proper sizing prevents distortion or inadequate visibility of designs, enhancing the overall appearance of the custom apparel.

What recent trends are shaping the future of DTF transfers in custom apparel?

Recent trends indicate a growing popularity of DTF transfers within the custom apparel market. Innovations in printing technology have led to softer textures and improved durability, while a rising demand for unique and personalized designs encourages more businesses to adopt DTF methods.

| Aspect | Details |

|---|---|

| What are DTF Transfers? | A printing method where designs are transferred from a special film to fabrics using heat, providing vibrant colors and detail. |

| Benefits | Versatile for various fabric types, high quality, durable, and soft textures. |

| Sizing Guidelines | – Small: 3-5 inches (logos) – Medium: 6-10 inches (front designs) – Large: 12-16 inches (back graphics) |

| Importance of Placement | Proper sizing and placement ensure visibility and aesthetic appeal, typically 3-4 inches from the neckline. |

| Recent Trends | Growth in popularity due to innovations and customer demand for personalized designs. |

| Setup Guidelines | Follow printer specifications for temperature and print resolution to achieve quality results. |

Summary

DTF Transfers are revolutionizing the custom apparel industry by offering unmatched versatility, durability, and high-quality results. As this guide highlights, understanding how to appropriately size and place DTF transfers is essential for maximizing their potential in your designs. Staying abreast of current trends, like innovations in printing technology, can significantly enhance your offerings and customer satisfaction. Embracing DTF Transfers not only caters to the growing demand for personalized designs but also positions your business competitively in the ever-evolving marketplace. Focusing on quality, adaptability, and nuanced design practices will undoubtedly lead to success in your custom apparel ventures.