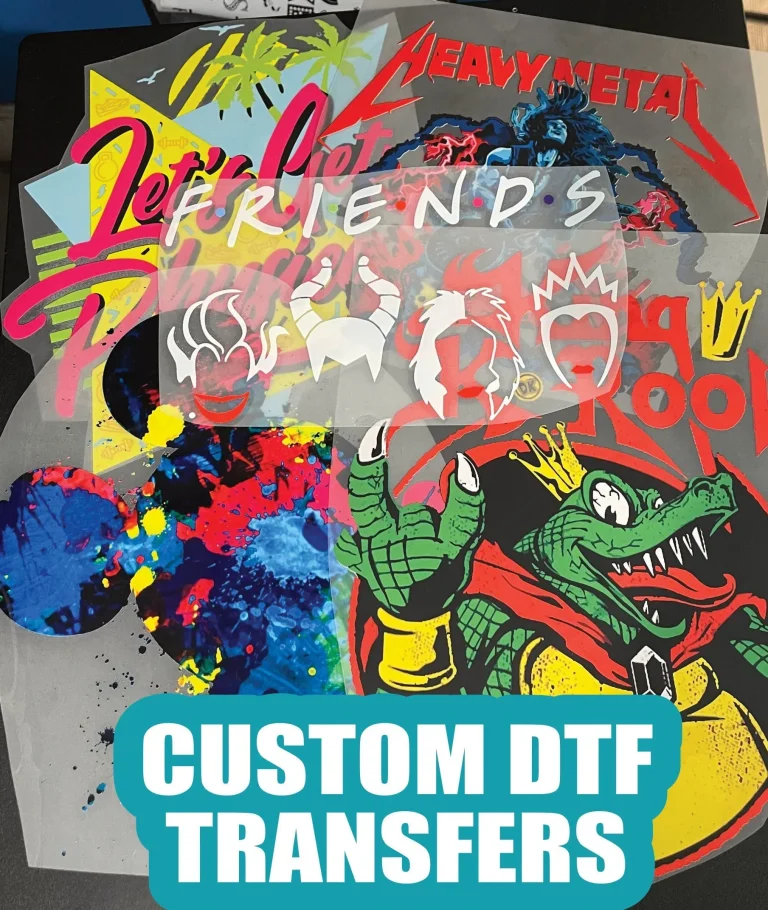

DTF transfers, or Direct-to-Film transfers, have emerged as a groundbreaking technique in the world of custom apparel decoration. Known for their ability to produce vibrant, high-quality images on a range of fabrics, DTF transfers are rapidly becoming a favorite among designers and decorators. The simplicity of the DTF process—printing designs onto a special film that is then heat-pressed onto garments—allows for intricate designs that are durable and wash-resistant. As the demand for custom apparel continues to grow, understanding how to effectively utilize DTF transfer techniques becomes essential for creators. This guide aims to simplify the various aspects of choosing the right DTF transfer size for your projects, ensuring that your designs not only stand out but also reflect the highest quality in craftsmanship.

Direct-to-Film transfers, often referred to as DTF printing, represent a modern milestone in the textile and apparel industry. This technique leverages the precision of inkjet printing to create intricate designs that can be transferred onto diverse fabric types. As creators navigate through custom printing projects, grasping the nuances of DTF printing techniques, including optimal transfer sizes, can significantly enhance their output. Whether it’s crafting cool t-shirt graphics or professional apparel, mastering the art of DTF can unlock numerous creative opportunities. In this article, we’ll explore essential tips for choosing the right DTF transfer size and techniques necessary for achieving standout results.

Understanding DTF Transfer Sizes

The selection of Direct-to-Film (DTF) transfer sizes is integral to maximizing the effectiveness of your print projects. Different sizes are designed for different applications, impacting both the visual appeal and practicality of the finished product. For example, smaller transfers work wonderfully for items such as children’s apparel or promotional products, where subtlety and detail are essential. On the other hand, larger transfer sizes, like those used for hoodies or backdrops, allow for dramatic illustrations and bold logos that can capture attention effectively.

Understanding how to navigate these sizes entails not only being familiar with standard dimensions—ranging from 8″x10″ for smaller applications to over 16″ for larger ones—but also recognizing the materials you’re working with. Diverse fabrics interact in unique ways with transfers of different sizes, and knowing the optimal size for your project ensures that colors stay vibrant and designs maintain their integrity throughout washes and regular wear.

Frequently Asked Questions

What factors should I consider when choosing DTF transfer sizes for my projects?

When selecting DTF transfer sizes, consider the type of project, the complexity of the design, and the garment size. Smaller transfers are great for delicate items like t-shirts, while larger sizes are suitable for hoodies or banners. Complex designs often benefit from smaller sizes to maintain detail, while bold graphics can shine with larger transfers.

How do I determine the right DTF transfer size for children’s clothing?

For children’s clothing, such as t-shirts or onesies, choose DTF transfer sizes that cover 50-65% of the chest width. This ensures the design is visible without overwhelming the garment’s aesthetics. Smaller sizes, between 8″x10″ to 11″x14″, are often most suitable for youth sizes.

Why is design complexity important when selecting DTF transfers?

Design complexity plays a significant role in choosing DTF transfers because intricate designs may lose detail on larger transfers. Smaller DTF transfers help preserve the clarity of detailed graphics, while larger ones can effectively showcase bold and simplified designs.

What are the latest techniques in DTF printing that affect transfer sizes?

Recent advancements in DTF printing, such as improved ink formulations and high-definition printing technologies, allow for more vibrant colors and better adherence to fabrics. These innovations mean that both small and large DTF transfers can achieve professional-quality results, enhancing the choice of size.

How does the choice of DTF transfer size impact my project budget?

Choosing the size of your DTF transfer directly affects project costs, as larger transfers generally incur higher material and printing expenses. Balancing quality with budget is crucial; larger transfers may be worth the investment for bold designs, while smaller sizes help minimize costs, especially for high-volume projects.

What should I know about using DTF transfers on various fabric types?

DTF transfers can be applied to different fabric types, including cotton, polyester, and blends. Understanding how each fabric interacts with the DTF process is vital; this knowledge helps inform your choice of transfer size, ensuring that designs maintain their vibrancy and durability across all fabric types.

| Aspect | Key Points |

|---|---|

| Understanding DTF Transfers | DTF transfers produce vibrant, high-quality images. The process involves printing on film and using heat to transfer the design. |

| Choosing the Right Size | For smaller items, choose sizes 8″x10″ to 11″x14″; for larger items, 12″x16″ or larger. |

| Project Type Impact | Match transfer size to the type of item (e.g., shirts vs. hoodies) for visual appeal. |

| Design Complexity | Detailed graphics favor smaller transfers; bold graphics can utilize larger sizes effectively. |

| Garment Size Consideration | Transfer should constitute 50-65% of the chest width for youth shirts; adults can use larger sizes. |

| Innovative Techniques | Advancements in printing technology improve print quality and speed, enhancing commercial use. |

| Cost Considerations | Larger transfers are costlier. Balance quality with budget constraints. |

| Recommended Sources | Refer to reputable articles for further insights and updates in DTF technology. |

Summary

DTF transfers are a revolutionary choice for custom apparel projects, emphasizing the importance of selecting the right size for your specific needs. By understanding the influences of project type, design complexity, and garment sizes, you can optimize the use of DTF transfers to achieve stunning results. Staying informed about the latest innovations in DTF printing technology will further enhance your projects, ensuring they stand out in a competitive market.