In the realm of custom apparel printing, DTF transfers, which stands for Direct to Film transfers, have emerged as a revolutionary option for vibrant fabric decoration. This innovative DTF printing technology allows for striking color vibrancy and intricate designs, making it a favorite among businesses and hobbyists alike. If you’re eager to dive into the world of custom apparel printing or simply want to understand how to use DTF transfers effectively, this guide will equip you with all the essential insights. Gain a competitive edge with the best practices for DTF transfer application and learn about the endless possibilities that come with this unique printing method. Embrace the future of garment decoration with the combination of quality and accessibility that DTF transfers offer.

Within the custom garment decoration landscape, the process of transferring designs directly onto textiles offers a myriad of possibilities for creative expression. Often referred to as film transfers or direct printing on film, this method provides an effective solution for detailed graphics and vivid colors on various materials. As individuals and businesses explore these modern techniques, understanding the nuances of personalized apparel generation becomes imperative. From exploring optimal techniques to implementing innovative printing solutions, this guide is designed to illuminate the path for enthusiasts eager to harness the advantages of this cutting-edge printing technology. Join us as we delve into the essentials of using film printing methods to expand customization options in the apparel industry.

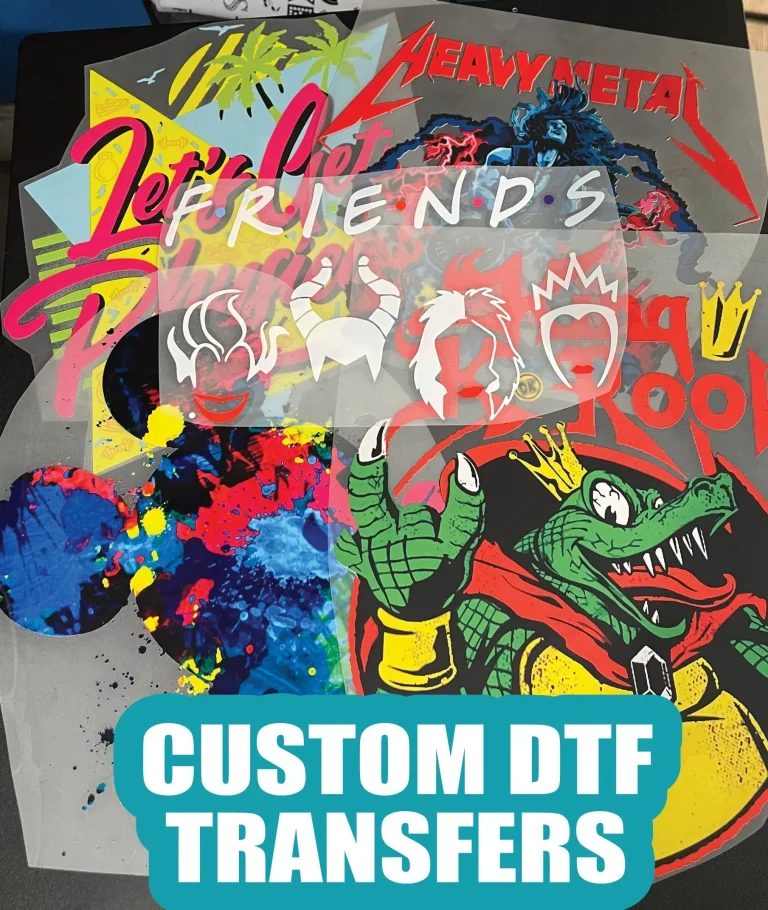

Understanding DTF Transfers: A Game Changer in Apparel Printing

DTF transfers, short for Direct to Film transfers, represent a revolutionary advancement in the realm of custom apparel printing. This printing technique is particularly favored for its ability to produce vivid colors and sharp details, making it a prime choice for intricate designs that might challenge traditional methods. With DTF printing technology, businesses can now enjoy efficient, low-cost production runs without sacrificing quality. This versatility is what draws many individuals and companies toward adopting DTF techniques for their customization needs.

As more businesses get on board with DTF technology, the market for custom apparel decoration is evolving rapidly. The ability to print directly on films allows for improved durability and longevity of prints, a significant advantage over some other methods. Especially for small businesses or entrepreneurs just starting, DTF transfers offer a cost-effective solution that aligns perfectly with today’s demand for personalized and unique garments.

Key Benefits of Using DTF Transfers

One of the standout benefits of DTF transfers is the vibrant color output they deliver. Unlike traditional screen printing, which can sometimes mute colors, DTF technology utilizes specialized inks that translate into rich, bright colors on the final product. This feature makes DTF transfers particularly appealing for those seeking high-impact visuals on their apparel. Furthermore, the durability of DTF prints means they can withstand repeated washing, maintaining their quality over time.

In addition to vibrant colors, DTF transfers offer exceptional versatility in terms of material compatibility. Whether you’re working with cotton, polyester, or blends, DTF transfers can adapt to various fabric types, which is essential for businesses aiming to diversify their product offerings. This adaptability not only makes DTF printing technology more appealing but also provides users the freedom to experiment with different garment styles and finishes.

Recent Innovations in DTF Technology

The DTF printing landscape is constantly evolving, with key players like Sam’s DTF Transfers and Insta Graphic Systems leading the charge. Recent launches and innovations, such as the ‘Insta DTF’ product line, are making waves by enhancing the vibrancy and durability of prints. These advancements signify a targeted approach towards meeting customer demands for high-quality printing solutions that are both efficient and reliable. As these companies roll out improved DTF products, they pave the way for aspiring entrepreneurs to enter the market with cutting-edge tools.

Moreover, Snuggle’s introduction of a dedicated DTF platform for personalized apparel demonstrates a clear trend towards customization in the fashion industry. This new platform is designed to simplify the process for trade printers and resellers, ultimately speeding up production times and meeting the growing consumer interest in unique, tailor-made clothing items. These innovations not only reflect changing market dynamics but also ensure that businesses are well-equipped to thrive in an increasingly competitive landscape.

How to Successfully Utilize DTF Transfers in Your Business

To effectively leverage DTF transfers in your business, it’s crucial to understand the steps involved from selection to application. Start by choosing the right DTF transfer that aligns with your design aesthetic and fabric type. The quality of the transfer itself can greatly impact the final output, so investing in high-quality options is essential for achieving optimal results in custom apparel printing.

Once you have selected your transfers, ensure that you properly prepare the garment surface for application. Preheating the area where the transfer will be applied is a best practice that eliminates moisture, ensuring a better adhesion. Following the recommended heat settings during application, usually between 320°F to 350°F, will also help maintain the integrity of your transfer and the vibrancy of the print.

Best Practices for DTF Transfer Application

Applying DTF transfers requires attention to detail and adherence to best practices to achieve long-lasting results. After selecting your transfers and preheating the garment, applying the right pressure with a heat press is vital. Maintaining consistent pressure during the heat application is key to ensuring that the transfer adheres properly without any peeling over time. Furthermore, once you’ve pressed the transfer, allowing it to cool before peeling back the film is essential for preserving the design.

Additionally, consider performing a secondary heat press after the initial peel. This step can significantly enhance adhesion and is recommended as part of the best practices for using DTF transfers. Once completed, advise your customers on proper care, such as washing garments inside out in cold water, to further extend the lifespan of the prints. By following these practices, businesses can maximize the potential of DTF technology and provide high-quality products to their customers.

The Impact of DTF Transfers on the Custom Apparel Market

The advent of DTF transfers has considerably impacted the custom apparel market, providing options that cater to diverse consumer tastes and preferences. With DTF printing technology, businesses can now offer a wider range of custom designs at competitive prices, effectively tapping into new market segments previously unreachable with traditional methods. The ability to quickly turn around orders and provide small runs has also empowered entrepreneurs to launch print-on-demand services, thus increasing the accessibility of custom apparel.

Moreover, the user-friendly nature of DTF transfers makes it easier for small business owners or hobbyists to dive into custom apparel printing without needing extensive training or significant capital investments. As the demand for personalized clothing continues to rise, DTF technology is set to become an integral part of the apparel industry, breaking barriers and allowing for unprecedented creativity and functionality.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a custom apparel printing method where designs are printed onto a special film using specialized inks. Once printed, the design is transferred to fabric with heat and pressure, producing vibrant, durable prints that are ideal for various materials.

What are the best practices for using DTF transfers effectively?

To ensure successful application of DTF transfers, follow these best practices: choose high-quality transfers, preheat the garment area, use a heat press set between 320°F and 350°F, peel the transfer carefully after cooling, and consider additional heat pressing for enhanced adhesion.

How does DTF printing technology compare to other printing methods?

DTF printing technology offers several advantages over other methods like screen printing and DTG printing. It provides vibrant colors, withstands washing, does not require large minimum orders, and works with various fabric types, making DTF ideal for small businesses and custom apparel.

Where can I find high-quality DTF transfers for my projects?

You can find high-quality DTF transfers at specialized print shops and online retailers that cater to custom apparel printing. It’s important to purchase from reputable suppliers to ensure vibrant and durable results.

How can I maximize the longevity of DTF transfers on garments?

To maximize the longevity of DTF transfers, wash the garments inside out in cold water, avoid harsh detergents, and refrain from using bleach. Additionally, avoid tumble drying and instead air dry to preserve the print quality.

What recent advancements have been made in DTF transfer technology?

Recent advancements in DTF transfer technology include the launch of premium services by companies like Sam’s DTF Transfers, new products from Insta Graphic Systems, and innovative platforms like Snuggle’s DTF service, all aimed at enhancing print quality and accessibility for custom apparel creators.

| Aspect | Details |

|---|---|

| Definition of DTF Transfers | A printing technology that transfers designs from film to fabric using heat and pressure, combining features of screen printing and DTG printing. |

| Key Advantages | 1. Vibrant Colors and High Detail 2. Versatile for various materials 3. Cost-effective for small runs 4. Quick turnaround times 5. User-friendly application process |

| Recent Developments | 1. Premium services by Sam’s DTF Transfers. 2. New products from Insta Graphic Systems. 3. Snuggle’s personalized apparel platform. 4. Best practices guide released. 5. Automatic DTF heat transfer press unveiled at PacPrint 2025. |

| How to Use DTF Transfers | 1. Choose the Right Transfer. 2. Prepare the Surface. 3. Heat Application. 4. Peel Diligently. 5. Post-Pressing Care. |

Summary

DTF transfers have emerged as a groundbreaking solution in the custom apparel printing industry, offering vibrant colors, versatility, and efficiency. As this innovative technology continues to develop, it presents an incredible opportunity for businesses and individuals alike to create high-quality, personalized garments. By leveraging the various advantages of DTF transfers, along with the latest advancements in the technology, users can achieve exceptional results in apparel decoration. This guide emphasizes the key aspects of DTF transfers, making it an essential resource for anyone interested in exploring this transformative printing method.