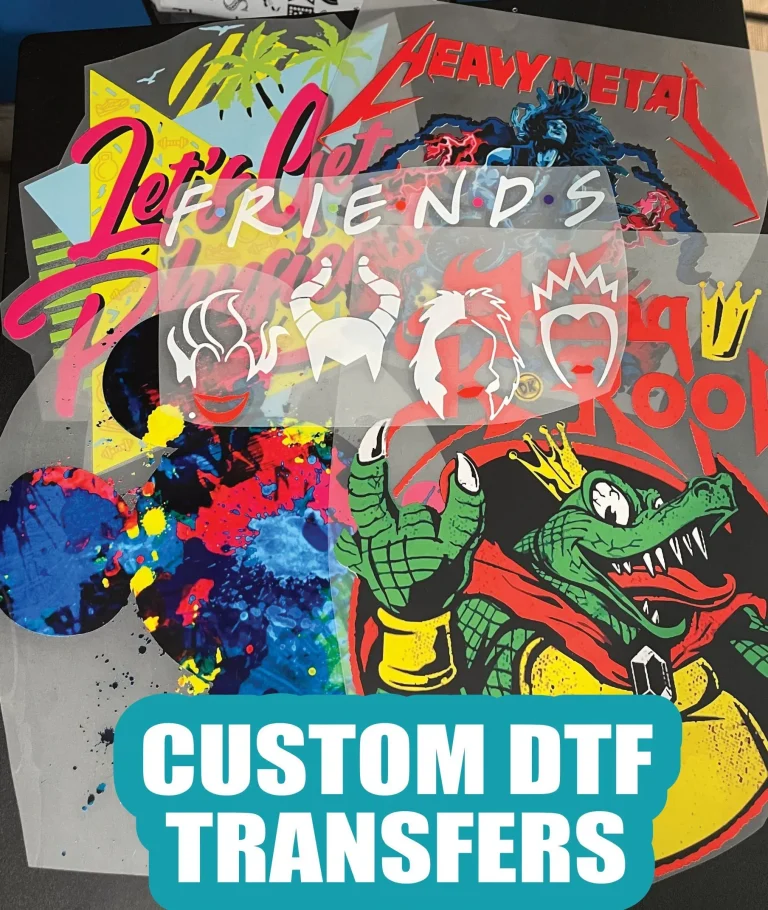

DTF transfers, or Direct to Film transfers, represent a groundbreaking advancement in the realm of custom apparel printing. As designers seek innovative ways to bring their creative visions to life, DTF printing emerges as a versatile method capable of producing high-quality prints on various fabric types. Unlike traditional printing techniques that may struggle with intricacy, DTF transfer technology excels in delivering sharp, vibrant, and durable designs, appealing to both personal and commercial projects. Its size versatility allows businesses to cater to a broad clientele, ensuring unique offerings from small logos to large graphics without sacrificing quality. This introductory segment will delve into the compelling advantages of DTF transfers and how they are shaping the future of custom printing with their exceptional production efficiency and performance.

Direct to Film printing, commonly referred to as DTF, is an emerging process in the custom clothing industry that offers numerous advantages. This innovative fabric decoration technique simplifies the production of detailed designs by employing cutting-edge transfer film that captures vivid colors and finer details. With an increasing demand for personalized apparel, many brands are turning to DTF for its ability to produce high-quality, long-lasting prints across various sizes, catering to a diverse range of consumer preferences. The adaptability of DTF technology not only enhances production efficiency but also opens doors to niche markets that require specific artwork or branding. As we explore the capabilities of DTF transfers, it becomes clear that this approach is redefining the landscape of custom printing with its remarkable quality and performance.

Understanding the Basics of DTF Printing

DTF printing, or Direct to Film printing, represents one of the most revolutionary advancements in the custom apparel industry. This technique involves creating high-quality prints by transferring designs directly onto fabric through a specialized process. At the core of DTF printing lies the use of a specialized film that captures intricate designs and colorful graphics. The versatility of DTF printing is not just in the output but also in the various materials it can be applied to, making it an attractive option for both small businesses and large-scale manufacturers.

What sets DTF apart from other printing techniques, such as screen or heat transfer methods, is its ability to produce vibrant, durable images in a wide range of sizes. This means businesses can fulfill diverse customer requests, whether they’re creating small emblematic prints or expansive full-coverage designs. Moreover, the ease of the DTF transfer process, from design preparation to heat application, streamlines production and increases overall efficiency in the apparel industry.

Exploring Size Versatility in DTF Transfers

One of the standout features of DTF transfers is their incredible size versatility. Businesses are no longer constrained by limitations imposed by traditional printing methods, which often require different setups for varied sizes. DTF technology caters remarkably well to this aspect, enabling artists and manufacturers to create anything from delicate designs on caps to large graphics that boldly cover the front of t-shirts or hoodies without losing quality. This adaptability is revolutionizing how brands approach custom apparel, allowing them to meet the evolving preferences of their customer base.

This level of versatility not only fosters creativity but also practical efficiency. The capability of DTF printing to seamlessly shift between small and large projects means fewer investments in different printing technologies. As order demands fluctuate, businesses utilizing DTF can efficiently manage both small runs for personalized gifts or larger orders for promotional merchandise, thus streamlining their production processes and enhancing overall customer satisfaction.

Quality and Durability of DTF Transfers

When considering custom apparel, quality and durability are critical factors that consumers look for. DTF printing excels in these areas as it produces high-quality prints that withstand the test of time. The transferred designs maintain their vibrancy and integrity, even after multiple washes, which is essential for everyday wear. DTF transfers adhere strongly to various fabric types, ensuring that the prints remain intact, and do not peel or fade quickly, unlike some traditional printing methods.

This durability is further amplified by the comfort offered by DTF prints. The technology used in printing results in a softer feel compared to thick vinyl or heavy ink layers typically associated with older methods. As a result, garments printed with DTF technology not only look good but feel comfortable against the skin, making them suitable for both casual wear and high-performance apparel.

Market Trends Favoring DTF Printing

The rise of e-commerce and consumer demand for personalized products have put DTF printing at the forefront of market trends in the custom apparel industry. As brands strive to engage consumers with unique offerings, DTF technology enables rapid production of customized items that resonate with customer individuality. The ability to print on demand has transformed how businesses approach inventory, reducing waste and allowing for flexible, responsive operations.

In addition, businesses are tapping into niche markets through DTF printing. The customization capabilities allow for specialized designs suitable for sports teams, events, and promotional campaigns. As brands venture into these segments, they can create tailored merchandise that speaks directly to their target audiences, enhancing brand loyalty and engaging more deeply with their consumer base.

Technological Advances in DTF Transfer Technology

As technology continues to evolve, the improvements in DTF transfer technology are noteworthy. Recent developments have led to faster drying times, which means quicker production cycles, particularly important for businesses managing large orders or working under tight deadlines. Innovations in curing processes ensure that prints are of superior quality, maintaining detail and color accuracy that meets consumer expectations.

Additionally, the introduction of integrated printing systems simplifies the workflow from initial design to the final transfer. With user-friendly interfaces and automated functionalities, even businesses with smaller setups can achieve high-quality outputs. The cost-effectiveness of adopting DTF technology allows larger adoption across different scales, from hobbyists to professional printers, further driving its popularity.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

DTF transfers involve printing designs onto a special film which is then transferred onto fabric using heat and pressure. The process includes design preparation, printing on film with DTF inks, applying adhesive, curing, and finally transferring the design to the fabric. This method is popular in custom apparel for producing high-quality, vibrant, and durable prints.

How does DTF printing enhance size versatility in custom apparel?

DTF printing excels in size versatility, allowing for prints of varying dimensions, from small logos to large graphics. This adaptability means businesses can cater to diverse customer needs without requiring multiple printing technologies, streamlining production and enhancing efficiency.

What are the benefits of using DTF transfer technology for high-quality prints?

DTF transfer technology offers high-quality prints that are vibrant, detailed, and durable. The prints are resistant to washing and provide a soft feel on fabrics, improving comfort compared to traditional printing methods. This quality makes DTF an ideal choice for custom apparel.

Why is DTF printing becoming more popular among businesses in the custom apparel market?

The rise of DTF printing is driven by the growing demand for customization in the apparel market, fueled by e-commerce trends. Businesses prefer DTF for its ability to produce complex designs quickly, enhance consumer engagement, and tap into niche markets effectively.

Can DTF transfers be applied to different fabric types?

Yes, DTF transfers exhibit strong adherence to various fabric types, making them versatile for different materials. This capability results in vibrant, long-lasting prints that maintain the breathability and comfort of the fabric, suitable for both casual and active wear.

What recent advancements have been made in DTF printing technology?

Recent advancements in DTF printing include faster drying times and improved detail preservation, optimizing printing speed and quality. New integrated systems equipped with user-friendly features are also making DTF technology more accessible for businesses of all sizes.

| Key Points | |

|---|---|

| What Are DTF Transfers? | DTF transfers are a modern fabric decoration method using specialized film to produce vibrant, high-quality prints. |

| Size Versatility | DTF transfers accommodate both small and large designs, allowing for diverse customization options. |

| Production Efficiency | DTF offers a streamlined approach to printing, enhancing productivity for both small and large orders. |

| Market Trends | The growing e-commerce sector has increased demand for personalized DTF printing solutions across various industries. |

| Quality and Performance | DTF transfers exhibit high durability and comfort, maintaining fabric breathability. |

| Technological Advances | Recent advancements have improved DTF efficiency, drying times, and detail preservation, making it accessible for many businesses. |

Summary

DTF transfers are quickly becoming a vital component in the custom printing industry. This innovative method not only allows for high-quality designs of varying sizes but also enhances production efficiency and meets the ever-changing demands of consumers who desire personalized products. As technology continues to advance, DTF printing stands poised to evolve further, ensuring that businesses can remain competitive by offering unique and tailored apparel options. Embracing DTF transfers not only elevates the creative possibilities for manufacturers but also provides consumers with an engaging and customized shopping experience, ultimately transforming the landscape of fashion and merchandise.