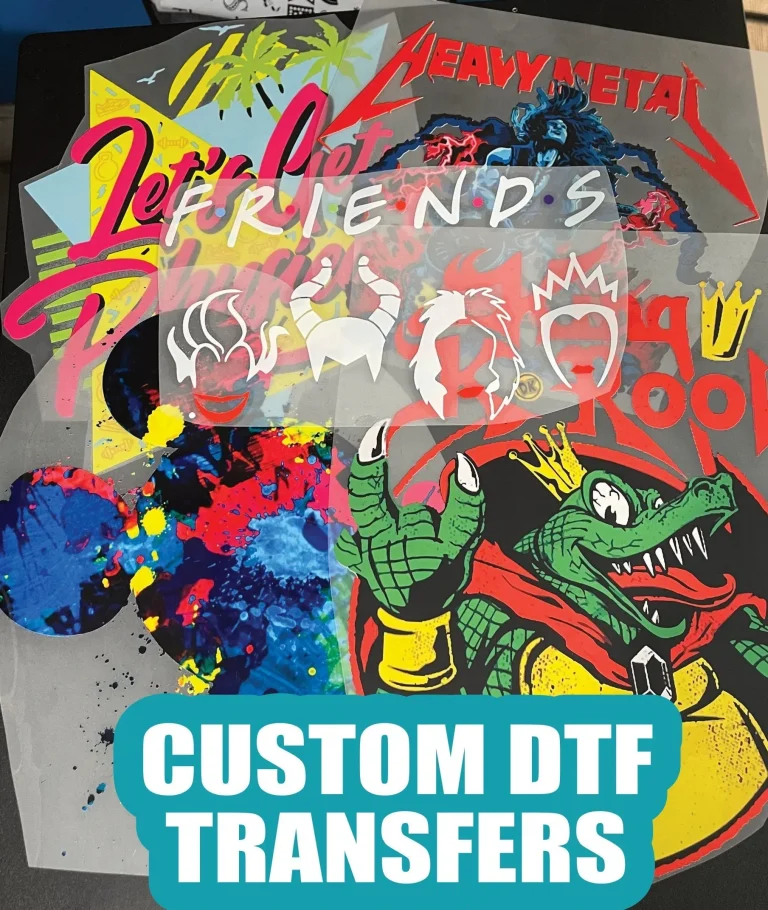

DTF transfers, or Direct to Film transfers, are revolutionizing the fabric printing industry with their impressive versatility and ability to produce striking designs. This groundbreaking printing technique allows artists and businesses to effortlessly create custom designs that can be applied to various fabric types, making it a favored choice for garment decoration. To truly maximize creativity, understanding how to size your designs appropriately is crucial for achieving eye-catching results. In this introduction, we will delve into the secrets of optimizing your use of DTF transfers, ensuring that your artistic expression is not only vibrant but also enduring. Get ready to explore creative techniques that will elevate your prints to new levels of excellence.

Also referred to as Direct to Film printing, DTF technology has emerged as a popular method for designing and decorating garments. This approach allows for intricate transfer of designs and vibrant colors onto an array of fabrics, broadening the scope for creativity and customization. By leveraging advanced printing techniques, users can create stunning artworks that stand out on various fabric types, catering to fashion enthusiasts and businesses alike. DTF printing opens up new avenues for expression, providing endless opportunities to engage with creative techniques that enhance the visual appeal of custom designs. From layering to mixing media, the world of fabric printing is more exciting and accessible than ever before.

The Versatility of DTF Transfers

DTF transfers are revolutionizing the garment printing industry with their unmatched versatility. This innovative technology allows for detailed designs and vibrant colors on a variety of fabric types, making it a favorite among designers aiming to maximize creativity. Whether you’re working with cotton, polyester, or blends, DTF transfers can easily adapt to different materials, ensuring that your ideas come to life without compromise.

Using DTF printing not only enhances the aesthetic of the garment, but it also extends its functionality. Designed to cater to intricate and colorful artistry, DTF transfers offer an excellent solution for artists who want to push boundaries. From casual wear to high-end fashion, this technique provides the foundation for any creative approach, making it easier than ever to produce custom designs that stand out in today’s competitive market.

Sizing Your DTF Designs for Maximum Impact

One of the essential considerations when working with DTF transfers is the sizing of your designs. Ideal dimensions typically range from 12 to 16 inches wide, ensuring clarity and vibrancy in color. Striking the right balance can significantly enhance the visual appeal of your creations. By experimenting with design sizes within this range, you can maintain the integrity of your graphics while captivating your audience with bold, eye-catching prints.

However, it is important to avoid oversized graphics that can lead to warping or quality loss during the heat transfer process. Carefully considering design placement on each garment type—from t-shirts to hoodies—can elevate the overall composition of the final product. Understanding how size and placement interact helps you create designs that not only look great but also convey your unique creative vision.

Exploring Creative Techniques with DTF Printing

To truly unleash your creative potential with DTF transfers, it’s crucial to explore advanced techniques. For example, layering multiple transfer designs can add depth and intrigue to your projects. This method creates a rich textural experience that captivates viewers while allowing you to showcase various elements of your design seamlessly.

Another exciting technique is color blocking, which utilizes DTF transfers of differing sizes and shapes to form cohesive, multi-dimensional designs. This method is favored in contemporary fashion scenes, where originality and modern aesthetic are key. Combining DTF printing with other creative methods like screen printing or embroidery can further enhance your projects, resulting in innovative and visually striking apparel.

Designing Custom Graphics for DTF Transfers

Creating custom designs for DTF transfers often involves professional design software like Adobe Illustrator or CorelDRAW. These tools enable designers to manipulate the size and format of their graphics effortlessly. By using vector graphics, you can ensure that your designs retain their quality and sharpness, regardless of any modifications made to their size.

Furthermore, the ability to tailor designs for different garment styles and sizes not only provides a personalized touch but also enhances customer satisfaction. This level of attention to detail establishes a strong foundation for your custom apparel offerings, allowing you to stand out in a crowded market while maximizing your creative expression.

Considering Fabric Selection in DTF Printing

Fabric selection plays a crucial role in maximizing creativity with DTF transfers. Quality materials such as cotton and polyester collaborate perfectly with DTF technology, ensuring vibrant prints that last. Cotton is appreciated for its softness and comfort, while polyester is known for its ability to showcase colorful prints effectively, making the choice of fabric integral to the overall design aesthetic.

Beyond common materials, exploring blends and unconventional fabrics opens up new avenues for creativity. Each fabric type responds differently to DTF transfers. Experimenting with unique textures and finishes allows for inventive designs that push the boundaries of traditional garment decoration, and can inspire unexpected yet stunning results.

The Rise of Personalization Trends in DTF Transfers

In recent years, personalization has become a driving force behind the increased popularity of DTF transfers in custom fashion. Consumers crave apparel that reflects their individual styles, and DTF technology provides an efficient way to cater to these desires. With the ability to produce limited edition designs, artists and designers can create unique pieces that set them apart from mass-produced clothing.

This emphasis on personalization not only enhances customer engagement but also fosters loyalty, as clients become invested in the stories and meanings behind their bespoke items. As a designer utilizing DTF technology, incorporating elements of personalization into your offerings is an effective strategy for boosting both sales and the emotional connection buyers have to your work.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing technology that allows for the creation of vibrant custom designs. This method involves printing designs onto a special film, which is then heat-pressed onto various fabric types. This process is celebrated for its ability to produce intricate details and rich colors that stand out on garments.

How can I maximize creativity with DTF transfers?

To maximize creativity with DTF transfers, focus on sizing, layering techniques, and experimenting with different fabric types. Using optimal design sizes (12 to 16 inches) ensures clarity, while layering transfers can add depth and texture to your prints. Additionally, combining DTF transfers with other creative techniques like color blocking can elevate your designs.

What are some effective creative techniques when using DTF printing?

Effective creative techniques for DTF printing include layering multiple DTF transfers for added texture, utilizing color blocking with diverse shapes and sizes, and mixing DTF with other methods like embroidery. These techniques can help to create unique custom designs that resonate well with the audience.

What fabrics work best with DTF transfers?

DTF transfers are compatible with various fabric types, including cotton and polyester. Each fabric reacts uniquely, with cotton offering softness and comfort, while polyester enhances color vibrancy and durability. Experimenting with fabric blends can lead to innovative and eye-catching designs.

How do design sizes influence DTF transfer results?

Design size is crucial for successful DTF transfers. Optimal sizes between 12 to 16 inches help maintain print integrity. Large designs may warp or lose quality, so testing different sizes in smaller increments can yield better results and ensure visual appeal on the final product.

What design software is recommended for creating custom DTF designs?

Software like Adobe Illustrator and CorelDRAW is highly recommended for creating custom DTF designs. These programs allow for easy size manipulation and enable the creation of high-quality vector graphics, ensuring your designs maintain clarity and detail during the DTF printing process.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | Versatile and innovative fabric printing technology that allows vibrant prints on various fabrics. |

| Understanding DTF Transfers | DTF is preferred for its intricate designs and vibrant colors. Involves printing on special film and heat transfer. |

| Sizing Considerations | Optimal size is 12-16 inches wide. Be cautious of oversized designs to avoid quality loss. |

| Creative Techniques | Techniques like layering, color blocking, and mixing media can enhance DTF designs. |

| Design Software | Tools like Adobe Illustrator help in size manipulation and creating high-quality vector graphics. |

| Fabric Experimentation | DTF works well on cotton, polyester and blends. Unique responses across different fabrics can inspire creativity. |

| Recent Trends in DTF | Customization and personalization are key trends, with an emphasis on limited edition designs. |

| Conclusion | Understanding sizing, experimenting with fabrics, and using innovative techniques enable impressive DTF creations. |

Summary

DTF transfers offer a remarkable opportunity for artists and businesses to bring their creative visions to life through versatile printing technology. By understanding the significance of design size, utilizing effective techniques, and experimenting with various fabrics, one can truly maximize the potential of DTF transfers. This innovative method not only supports intricate and vivid designs but also caters to the ever-growing desire for personalized and unique apparel. Whether for commercial production or personal projects, embracing the DTF transfers process unlocks a world of creative possibilities.