DTF Transfers, or Direct-to-Film transfers, represent a revolutionary advancement in the world of custom printing, making it easier than ever to create vibrant, high-quality designs. This modern printing method has rapidly gained popularity among hobbyists and professionals alike, thanks to its versatility and ability to produce stunning results on a wide range of textiles. With DTF printing, users can achieve exceptional print quality enhancement that stands the test of time, ensuring that their designs remain bright and bold. In this guide, we’ll delve into essential DTF printing tips and techniques that can elevate your projects, whether you’re crafting unique clothing items or promotional materials. As the demand for innovative printing techniques continues to rise, mastering DTF transfers will undoubtedly give you a competitive edge in the custom textile printing market.

Direct-to-Film transfers, often referred to as DTF printing, have transformed how designs are applied to various materials in the printing industry. This innovative method involves printing on a specialized film that captures high-resolution images, which are then heat-pressed onto fabrics, yielding stunning results. Unlike traditional printing techniques, DTF offers the flexibility to work with multiple substrates, making it ideal for diverse applications such as fashion and promotional items. With a focus on quality and durability, learners are encouraged to explore essential DTF printing tips that can assist in achieving impeccable outcomes. By understanding the intricacies of this modern printing approach, businesses and creative professionals can maximize their output, ensuring their designs are both beautiful and long-lasting.

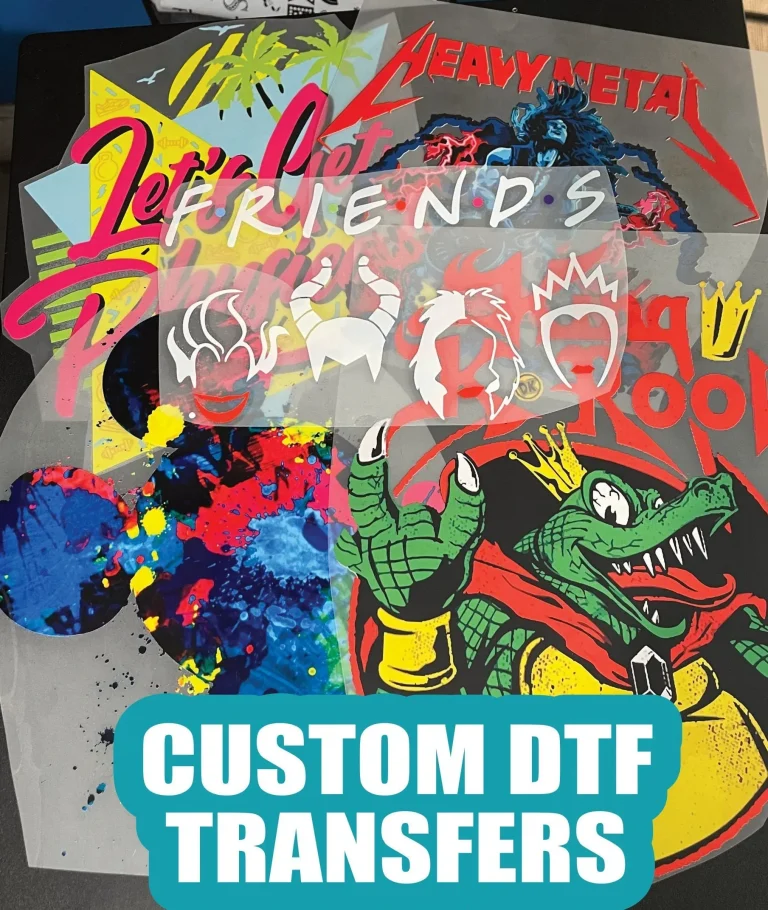

The Rise of DTF Printing

Direct-to-Film (DTF) printing has become increasingly popular in the world of custom textile printing. This method offers a versatile solution for those looking to create intricate designs with vibrant colors on various fabrics. Compared to traditional printing techniques, such as screen printing or heat transfer vinyl (HTV), DTF transfers allow for more detailed imagery and can accommodate complex designs with ease. As a result, many businesses and individuals are turning to DTF printing as their go-to option for high-quality print outcomes.

The flexibility of DTF printing is particularly advantageous, as it supports a wide range of materials, including cotton, polyester, and blends. This adaptability not only appeals to fashion designers and apparel brands, but also to companies aiming to produce custom promotional items. As the demand for personalized products rises, understanding the benefits of DTF transfers enables creators to stay ahead in today’s competitive market.

Key Benefits of Using DTF Transfers

One of the primary benefits of DTF transfers is their ability to produce stunning print quality. The high-quality eco-solvent inks used in the DTF printing process lead to exceptional color brilliance that stands out on any fabric. This is particularly important for businesses seeking to create eye-catching designs that attract customers. By leveraging the advanced features of DTF technology, you can create prints that are not only visually appealing but also durable and long-lasting.

Moreover, DTF transfers enhance workflow efficiency by simplifying the printing process. Unlike other traditional methods that require multiple steps and complex setups, DTF printing streamlines the entire process. With proper artwork preparation and optimal print settings, printers can quickly produce multiple transfer designs, significantly reducing turnaround times for order fulfillment. This efficiency is crucial for meeting the fast-paced demands of today’s marketplace.

Essential Tips for Optimizing DTF Printing

To achieve the best results with DTF printing, there are several critical tips to consider. First, ensure that your printer is set to a minimum resolution of 1200 DPI to capture the fine details of your designs effectively. This high resolution is essential for achieving the crisp clarity that distinguishes quality prints. Additionally, pay attention to your heat press settings—maintaining the right temperature and pressure during the transfer process is vital for ensuring proper adhesion and longevity of the print.

Another key factor in optimizing your DTF printing is the importance of using high-quality materials. Select top-notch inks and films known for their compatibility with various fabrics. The quality of your materials directly impacts the print outcome and durability. By investing in the right supplies, you can enhance the overall performance of your DTF printing. Conducting sample tests on different fabrics can also yield valuable insights, helping you refine your approach for maximum impact.

Artwork Preparation for DTF Printing

The preparation of your artwork is one of the most crucial aspects when it comes to DTF transfers. For optimal results, it is advisable to create your images in formats that retain transparency, such as PNG or vector files. Using design software, like Adobe Illustrator, allows for comprehensive editing and ensures that your designs are perfectly adapted for transfer. This attention to detail not only saves time but also contributes to the production of high-quality prints that align with client expectations.

Additionally, consider the color settings when preparing your artwork. Choosing the right color profiles can greatly influence the final print’s vibrancy and accuracy. It’s essential to convert your designs to the appropriate color space, typically CMYK, to maintain color fidelity before printing. Properly formatted artwork lays the foundation for successful DTF transfers, ultimately leading to professional-looking results.

The Importance of Layering Techniques

Understanding layering techniques is vital for creating intricate, multi-colored designs with DTF printing. When layering, it is essential to start with your base colors and build up to the top colors gradually. This method not only helps in achieving depth and dimension but also maintains clarity in the final design. Incorrect layering can lead to muddled prints, so experiment with various approaches to find the layering order that works best for your specific designs.

Moreover, utilizing transparent layering can enhance the impact of your artwork, enabling colors to interact beautifully on the fabric. By adjusting transparency levels, designers can create visually appealing gradients and unique textures that distinguish their work in a competitive market. Mastering layering techniques can significantly enhance the quality of your DTF prints, making your creations stand out and resonate with your audience.

Maintaining Quality Post-Printing

After completing the DTF printing process, it’s crucial to consider the long-term preservation of your prints. Providing proper care instructions to your customers plays a significant role in maintaining the vibrancy and integrity of the printed items. Recommend washing DTF-printed garments in cold water and avoiding the use of fabric softeners. These practices help prevent fading and prolong the life of the prints, ultimately ensuring customer satisfaction and fostering repeat business.

Additionally, consider implementing quality checks after the printing process. Inspect each transfer for any imperfections before packaging or delivering the product to customers. Establishing a systematic approach to post-print quality assurance can save time and resources while significantly enhancing your brand’s reputation. This attention to detail in post-processing will reflect positively on your business and help build a loyal customer base.

Frequently Asked Questions

What are DTF transfers and how do they work in custom textile printing?

DTF transfers, or Direct-to-Film transfers, are a revolutionary printing technique where images are printed onto a special film and then heat-pressed onto various textiles. This method offers vibrant, durable prints on materials such as cotton, polyester, and blends, making it ideal for custom textile printing.

What materials are necessary for high-quality DTF printing results?

To achieve high-quality DTF printing results, it is crucial to use premium eco-solvent inks and compatible films. Quality materials ensure better adhesion and vibrant colors, leading to prints that withstand multiple washes without fading or degrading.

What are some essential DTF printing tips for beginners?

Beginners in DTF printing should focus on using high-resolution images, calibrating their printers for optimal settings (at least 1200 DPI), and adhering to heat press guidelines (around 320°F for 30-40 seconds). Proper artwork preparation and using the right materials are also key DTF printing tips for success.

How does layering impact the final quality of DTF prints?

Layering is a critical technique in DTF printing, especially for multi-colored designs. By starting with a base color and adding layers in the correct order, you ensure clarity and vibrancy in your prints. Improper layering can result in muddied images, so experimenting with layering techniques is essential for quality outcomes.

What care should be taken after applying DTF transfers to preserve print quality?

To preserve the quality of DTF transfers, wash printed garments in cold water and refrain from using fabric softeners, as they can affect the ink’s durability. Proper post-processing care helps prolong the life of the prints, ensuring customer satisfaction and repeated business.

Why is it essential to invest in quality equipment for DTF transfers?

Investing in reliable equipment, such as a quality heat press specifically designed for DTF transfers, is essential for achieving consistent results. Uniform pressure and regular maintenance of your printer and heat press can significantly enhance print quality and longevity.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | DTF transfers are a revolutionary printing method catering to increasing demands for custom prints among hobbyists and professionals. |

| Understanding DTF Transfers | DTF printing involves transferring images printed on a special film to various substrates using high-quality inks. |

| Quality Materials Matter | Using high-quality inks and films is essential for achieving vibrant and durable prints. |

| Optimal Print and Heat Settings | Maintaining a printer resolution of at least 1200 DPI and using a heat press at 320°F ensures quality transfers. |

| Artwork Preparation Techniques | Proper artwork setup in formats like PNG or vector can enhance the final print quality. |

| Layering for Impact | Utilizing layering techniques is crucial for creating multi-colored designs effectively. |

| Post-Processing: Preserving Quality | Post-application care is vital to maintaining print quality and customer satisfaction over time. |

| Experimenting with Different Fabrics | Testing various fabrics helps understand which materials best receive DTF prints, offering creative opportunities. |

| Investing in Reliable Equipment | Investing in high-quality heat presses and regular maintenance is key to achieving consistent results. |

Summary

DTF transfers represent a transformative opportunity to maximize your printing capability in the burgeoning custom printing landscape. This innovative printing technique not only produces eye-catching designs but also adapts well to various materials, making it an essential tool for individuals and businesses alike. By focusing on quality materials, precise techniques, and thorough post-processing care, you can achieve professional-grade results that captivate customers and stand out in a competitive market. Embrace the versatility and efficiency of DTF transfers to elevate your custom printing projects.