DTF transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom printing solutions for small businesses. This innovative printing technique allows for vibrant and high-quality prints on a variety of materials, including textiles and leather, catering to diverse customer needs. With its cost-effective printing model, DTF provides small enterprises the opportunity to create intricate designs without the burden of high startup costs. Additionally, DTF transfers offer eco-friendly printing options, using water-based inks that reduce environmental impact—an essential consideration for today’s conscious consumers. Join us as we delve into the numerous benefits of DTF transfers and discover how this technology can enhance your business operations and product offerings.

In the realm of innovative printing, Direct-to-Film (DTF) technology has emerged as a leading option for enterprises looking to streamline their operations and deliver high-quality products. Often referred to as film transfer printing, this technique enables businesses to achieve impressive visuals that can adhere to an extensive range of materials. Additionally, with the rising demand for sustainable practices, alternatives like eco-conscious film printing make it easier for brands to attract environmentally aware customers. These versatile printing solutions not only cater to niche markets but also empower small business owners to expand their creativity and product lines. As we explore the advantages of DTF technology, it’s clear that this method is paving the way for a new era in the printing industry.

Understanding Direct-to-Film Transfers

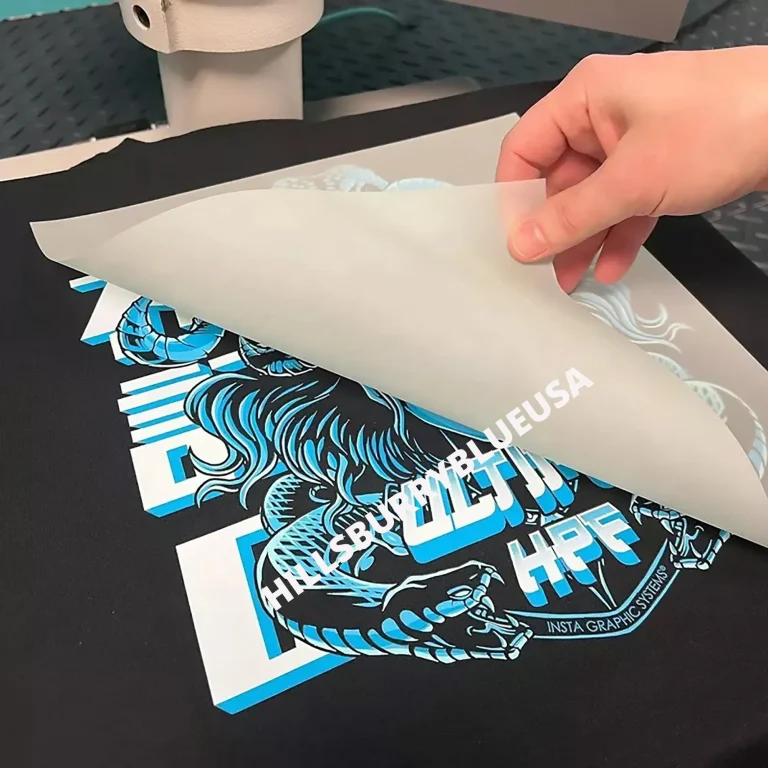

Direct-to-Film (DTF) transfers are revolutionizing the way small businesses approach custom printing solutions. This innovative method allows for high-quality images to be transferred directly onto fabrics, creating vibrant designs that resonate well with consumers. The DTF process utilizes a specialized printer that applies inks onto a film, which is then pressed onto the fabric using heat, ensuring that the prints are both durable and visually stunning.

Unlike traditional printing methods, DTF transfers can work on a variety of fabrics, including cotton, polyester, blends, and even leather. This versatility opens up a world of possibilities for small businesses, enabling them to diversify their product offerings and cater to a broader audience. As consumer demands for unique and high-quality apparel grow, adopting DTF technology can place small enterprises at a competitive advantage.

Frequently Asked Questions

What are DTF Transfers and how do they work?

Direct-to-Film (DTF) Transfers are a cutting-edge printing technique where artwork is printed onto a special film and then transferred to the desired fabric using heat. This method allows for vibrant and detailed designs, making it an excellent choice for small business printing solutions.

Why should small businesses choose DTF Transfers for custom printing solutions?

Small businesses should consider DTF Transfers due to their cost-effectiveness and quality output. Unlike other printing methods, DTF offers a lower initial investment and minimal setup costs, allowing businesses to produce high-quality prints without breaking the bank.

Are DTF Transfers eco-friendly compared to other printing methods?

Yes, DTF Transfers are eco-friendly as they often utilize water-based inks, which have a lower environmental impact than traditional printing methods. This sustainable approach can attract eco-conscious consumers, enhancing a brand’s reputation.

Can DTF Transfers be used on various fabrics?

Absolutely! One of the key advantages of DTF Transfers is their versatility. They can be applied to a wide range of fabrics, including cotton, polyester, blends, and even leather, making them perfect for diverse product offerings in small business printing.

What are the durability and wash resistance characteristics of DTF Transfers?

DTF Transfers are known for their exceptional durability and wash resistance. The prints maintain their vibrancy and integrity even after multiple washes, providing customer satisfaction and reducing product returns, which is crucial for small businesses.

How do DTF Transfers enhance production times for small businesses?

DTF Transfers significantly streamline the printing process, allowing for rapid production times. This efficiency enables small businesses to fulfill customer orders quickly, especially during peak seasons, thereby improving customer relationships and boosting sales.

| Key Points | Description |

|---|---|

| High-Quality Prints | Produces vibrant, high-resolution images that stand out on various fabrics. |

| Versatility | Can print on multiple materials including cotton, polyester, and leather. |

| Cost-Effective | Requires lower initial investment and reduces production costs for small runs. |

| Ease of Use | No pre-treatment is required, making it easy for businesses to adopt. |

| Durability and Wash Resistance | Maintains image integrity through numerous washes, enhancing customer satisfaction. |

| Rapid Production Times | Facilitates quick turnaround to meet customer orders and demands. |

| Ecological Aspects | Utilizes water-based inks, resulting in lower environmental impact. |

| Recent Developments | Introduction of compact and affordable printers that enhance accessibility. |

Summary

DTF Transfers offer small businesses a contemporary solution to enhance their custom printing processes. The technology not only emphasizes cost-effectiveness but also delivers high-quality and versatile printing options. By embracing DTF transfers, small enterprises can significantly augment their product range while ensuring exceptional durability and rapid production capabilities. These advantages are crucial for businesses aiming to excel in competitive markets. Additionally, the eco-friendly nature of DTF printing aligns with the growing consumer demand for sustainability. As the DTF technology landscape continues to advance, adopting such innovative printing solutions is essential for any small business looking to thrive.