DTF transfers, or Direct to Film transfers, are transforming the landscape of fabric printing by allowing designers to create vivid, high-quality images that capture attention. This innovative process involves printing images onto a specialized film that is then transferred onto various materials using heat. One of the key features of DTF printing is its ability to produce intricate designs with a level of detail that was previously difficult to achieve. However, a crucial factor that influences the success of these prints is the size of the transfer, as it directly impacts the resolution and overall quality. In this article, we will explore the various implications of DTF transfer size, including DTF ink usage and the importance of resolution, to ensure outstanding results every time.

In the realm of fabric customization, Direct to Film printing has emerged as a game-changer, revolutionizing how designs are applied to textiles. Often referred to as film transfers, this technique utilizes heat to embed vibrant and detailed graphics onto different materials. Understanding how the dimensions of these film transfers affect the printing process is essential for achieving excellent results, particularly in custom applications. From assessing image clarity to optimizing ink consumption, many components come into play based on transfer size. As we discuss these aspects further, the importance of mastering DTF transfer resolution and techniques will become clear.

Understanding DTF Transfers: A Comprehensive Overview

Direct to Film (DTF) transfers have emerged as a game-changer in the world of fabric printing. This innovative technique transfers vibrant and detailed images onto textiles using a specialized film and adhesive powder. By providing flexibility in design and material application, DTF printing has become a preferred choice for many custom apparel businesses. Understanding how this process works is essential for anyone looking to capitalize on its benefits.

The DTF printing process involves several key steps, including printing onto the film, applying adhesive, and curing the print before it’s transferred to fabric. One of the advantages of DTF is its compatibility with various materials, allowing for a wide range of applications beyond traditional fabrics—such as leather, and canvas. This versatility makes DTF printing a valuable option for both producing high-quality merchandise and fulfilling unique customer demands.

The Role of Size in DTF Transfer Quality

The impact of transfer size is significant when it comes to delivering high-quality DTF prints. Larger transfers require careful consideration regarding resolution and clarity; the DPI setting plays a crucial role in determining whether a design appears sharp or pixelated. For sizes above a certain threshold, it’s advisable to use a DPI of at least 300 to maintain optimal details in the image. Failing to do so can lead to disappointing results, particularly when printing intricate designs.

In addition to resolution, larger sizes also challenge printers in terms of ink coverage. The more substantial the transfer, the greater the volume of ink needed, which can potentially lead to an increase in overall production costs. Consequently, proper management of ink usage is essential for ensuring both quality and cost-effectiveness in larger prints. Adjusting ink spray and coverage settings based on the transfer size can help maintain a balance between saturation and clarity.

Maximizing DTF Transfer Resolution

Resolution is a defining factor in the success of DTF prints. When producing transfers, particularly large ones, achieving and maintaining high resolution is paramount for both aesthetic appeal and consumer satisfaction. A larger size can inherently compromise the details of an image if not meticulously addressed, leading to a lack of professionalism in the final product.

To counterbalance the challenges presented by size, utilizing high-resolution settings and quality film is imperative. Investing in high-quality DTF inks that facilitate exceptional color saturation and vibrancy can further enhance the outcome. Practicing these techniques ensures that even the most complex designs retain their intended visual impact, regardless of their dimensions.

Impact of DTF Ink Usage on Transfer Quality

Understanding DTF ink usage is essential for printers, particularly regarding its relation to transfer size. Larger designs tend to require more ink, which can introduce complications such as uneven distribution and longer curing times. Overuse can lead to situations where ink bleeds, compromising design integrity. Careful control of ink usage not only preserves the quality of larger prints but also minimizes waste and cost.

Efficient management of DTF ink begins with determining the optimal amount needed for any given design size. This includes calibrating printers to ensure that the initial spray does not oversaturate the fabric yet provides enough coverage for vibrant colors. Additionally, selecting high-quality inks that are designed for DTF applications can significantly reduce problems associated with larger transfers.

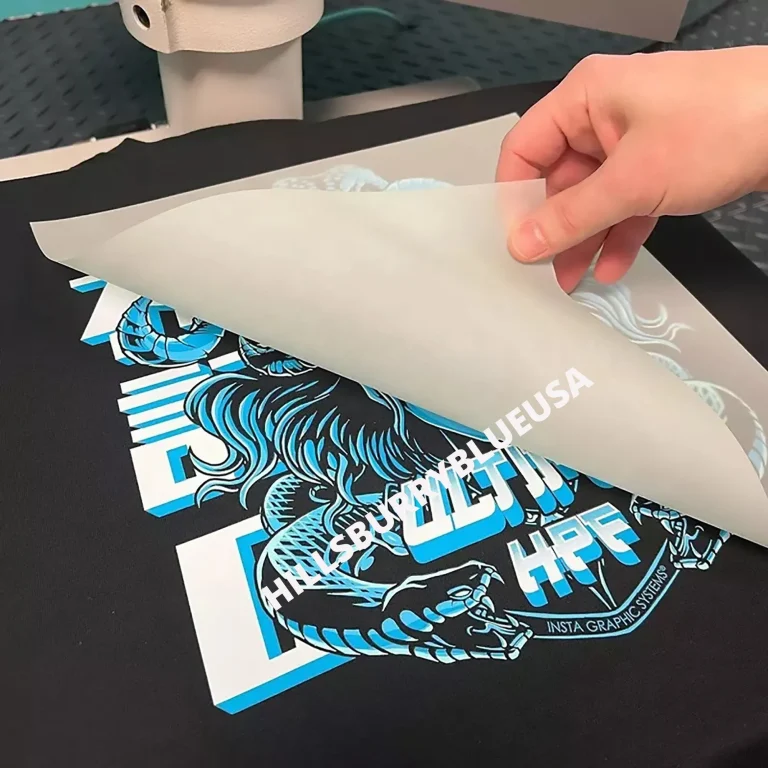

Techniques for Applying DTF Transfers Effectively

Application techniques are essential in determining the success of DTF transfers, especially as size increases. Larger transfers may necessitate different methods, such as adjusting the heat and pressure settings on the heat press to ensure proper adherence to the fabric. Failure to adequately calibrate these variables can result in issues such as ghosting, where the transfer does not stick correctly, leading to blurred designs.

Moreover, familiarity with a variety of application materials can enhance the effectiveness of DTF printing. Knowing how different fabrics react to larger transfers allows printers to pre-test and adapt their methods accordingly. By tailoring the application approach to the size and type of fabric, businesses can minimize potential defects and enhance the overall quality of their products.

Evolving Trends in DTF Printing Sizes

As the demand for customization continues to rise, the trends in DTF printing are shifting, particularly in relation to transfer sizes. Many customers are seeking unique, personalized designs, which require print shops to be versatile and adaptive. Staying attuned to market preferences not only helps businesses cater to consumer desires but also positions them competitively in a growing industry.

The latest advancements in DTF technology are facilitating better results across varying sizes, with improved ink distribution systems and curing techniques. This evolution not only helps mitigate challenges associated with larger transfers but also ensures high-quality outputs that satisfy the increasing consumer demand for intricate and customized prints.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a modern technique that transfers high-quality images onto fabrics using a heat application process. It involves printing an image onto a special film coated with hot-melt adhesive powder, which is then heat-pressed onto the desired fabric. This method allows for vibrant colors and intricate designs, making it popular for custom apparel.

How does DTF printing size impact the quality of the transfer?

The size of DTF transfers significantly influences the print quality and resolution. Larger transfers require a higher DPI (at least 300) to maintain clarity and detail, ensuring the final output does not appear pixelated. Thus, careful measurement and design adjustments are essential for optimal results with larger DTF prints.

What should I consider regarding DTF transfer resolution?

When planning for DTF transfers, resolution is crucial. A higher DPI setting is necessary for larger designs to ensure that details remain sharp. Poor resolution in DTF printing can lead to a blurry or pixelated appearance, which negatively affects the overall quality of the transferred image on the fabric.

What are the implications of ink usage in DTF printing?

DTF ink usage varies with transfer size; larger designs typically use more ink, impacting both production costs and drying times. Over-saturation from excessive ink can lead to color bleeding and diminished print quality. Thus, managing ink application is critical, especially for larger DTF transfers.

How do application techniques vary for different DTF transfer sizes?

Application techniques for DTF transfers must be adjusted based on size. Larger transfers may require increased heat and pressure to ensure the design adheres properly to the fabric. This involves modifying pressing time and temperature settings to prevent defects such as ghosting that can arise from improper application.

What should I know about using custom DTF printing for various materials?

Custom DTF printing considerations vary based on the fabric used. Larger transfers on materials like spandex may risk distortion when the fabric is stretched. Understanding fabric properties and testing with various transfer sizes is essential for maintaining design integrity, particularly with intricate printing.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A method of transferring high-quality images onto fabrics using a special film and hot-melt adhesive. |

| Resolution Considerations | Larger transfers require higher DPI (300+) to maintain image clarity and prevent pixelation. |

| Ink Usage | Bigger transfers use more ink, affecting drying times and costs; careful management is essential to avoid defects. |

| Application Techniques | Larger transfers require adjustments to heat and pressure settings to ensure proper adhesion and prevent ghosting. |

| Material Considerations | Fabric type influences how larger transfers behave; testing is key for successful results. |

| Recent Trends | Advancements in DTF technology improve size accuracy and ink distribution, easing challenges with larger designs. |

| Customization Demands | Increasing consumer interest in unique designs pushes businesses to adapt transfer sizes for better service. |

| Market Insights | The DTF market is growing due to the ability to quickly produce personalized items, highlighting size’s importance. |

Summary

DTF transfers have become an essential printing method for customized apparel and promotional items, significantly influencing the quality of these products. Understanding how the size of the transfer affects factors such as resolution, ink usage, application techniques, and fabric interactions is critical for achieving high-quality results. As technology progresses and consumer demand for personalized designs rises, staying informed about the dynamics of size in DTF transfers will empower businesses to meet market needs effectively and enhance overall product quality.