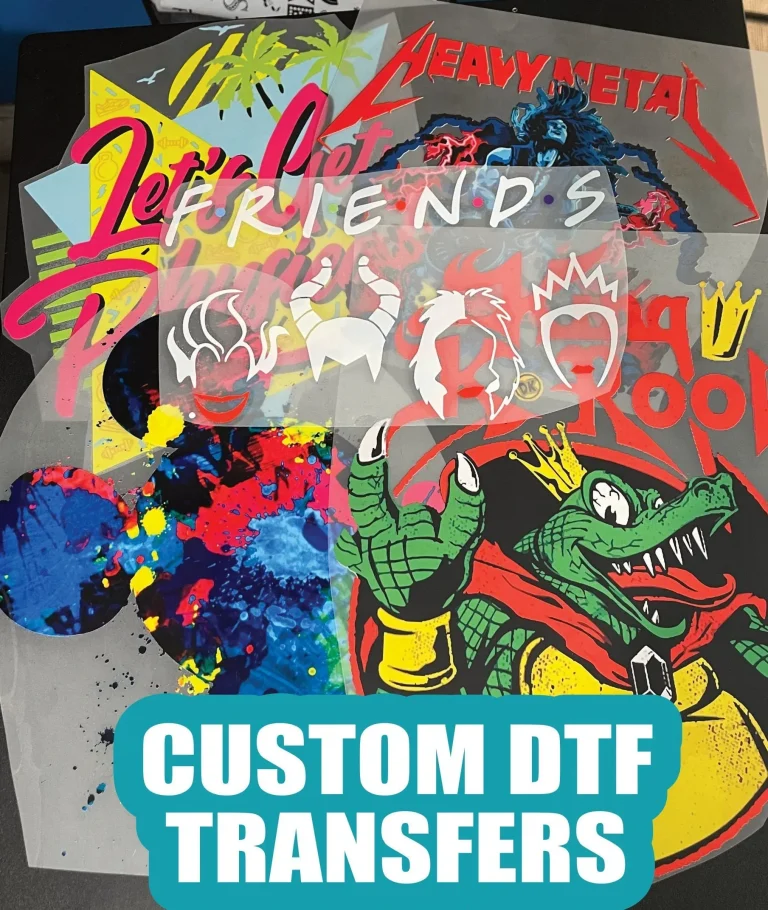

DTF Transfers, or Direct-to-Film transfers, have revolutionized the custom apparel industry with their ability to produce stunning, high-quality prints. This innovative printing process involves transferring intricate designs onto fabrics using special films, making it a preferred choice for businesses and artists alike. The DTF printing process not only delivers vibrant colors and detailed graphics, but it also offers versatility for various fabric types. As consumers increasingly seek personalized clothing options, DTF technology stands out for its efficiency and attention to detail. Moreover, sustainable printing options are becoming more prominent in this space, marking a significant trend towards eco-friendliness in garment printing.

Known as direct-to-film printing, DTF transfers serve as a cutting-edge method to custom print designs onto garments. This technique allows for the seamless transfer of intricate artwork from a specially treated film to various fabrics, making it an ideal choice for anyone in the custom apparel sector. With its user-friendly application and vibrant outputs, the DTF printing process has gained widespread popularity among both small businesses and larger manufacturers. As the demand for personalized products continues to grow, advancements in DTF technology are paving the way for more creative and sustainable printing solutions in the fashion industry. This emerging trend not only meets consumer desires but also promotes a greener approach to apparel production.

Understanding the DTF Printing Process

The DTF printing process is a revolutionary technique in the world of garment creation. By utilizing a specialized film that acts as a carrier for vibrant inks, designers can transfer intricate designs onto fabric with ease. The process involves several key stages, beginning with a well-crafted design that is printed onto the film using high-quality CMYK inks. This methodology not only ensures that the colors are vibrant but also that they maintain their integrity on various fabric types, making DTF printing ideal for a wide array of custom apparel.

In essence, the DTF printing process is rooted in precision and technology. After creating an eye-catching design, the DTF printer goes to work, layering colors while also applying an adhesive that secures the print bond to the fabric. This comprehensive approach to garment decoration highlights why DTF has rapidly garnered popularity among fashion enthusiasts and industry professionals alike.

Advantages of DTF Transfers in Custom Apparel

DTF transfers are a game changer for custom apparel, offering numerous advantages that set them apart from traditional printing methods. First and foremost, the versatility of DTF technology allows for a wide range of designs, from complex images to simple logos, all of which can be printed quickly and efficiently. This means that businesses can easily cater to varying customer demands without the risk of overproducing, keeping inventory low and operations sustainable.

Moreover, DTF transfers are known for their exceptional quality and durability. Unlike other printing methods, DTF prints can withstand multiple washes without losing vibrancy or peeling. This durability not only enhances customer satisfaction but also solidifies brand loyalty among those seeking reliable and lasting custom apparel.

The Role of Sustainability in DTF Printing

As the fashion industry increasingly prioritizes sustainability, DTF printing emerges as a responsible choice. With advancements in eco-friendly inks and films, DTF transfers are paving the way for sustainable printing options that do not compromise on quality or aesthetic appeal. These environmentally-conscious alternatives allow businesses to minimize their carbon footprint while still providing high-quality custom apparel.

Additionally, the DTF printing process is more efficient compared to traditional methods, leading to less waste and energy consumption during production. By adopting DTF technology, businesses are not only enhancing their operational practices but are also aligning themselves with a growing consumer base that values sustainable fashion initiatives.

Innovations in DTF Technology

The landscape of DTF technology is undergoing rapid innovations that enhance its efficacy and accessibility. Recent advancements focus on improving printing speeds and ink formulations, which have made DTF printers more efficient than ever. Such innovations lower production costs and provide users with the advantage of faster turnaround times, an essential factor in today’s fast-paced fashion world.

Furthermore, manufacturers are developing user-friendly interfaces that streamline the printing process for operators. This ease of use draws more small business owners into the DTF printing arena, thus democratizing the technology and expanding its reach across diverse markets.

Market Trends in DTF Printing

The DTF printing market is witnessing substantial growth, driven largely by consumer demand for personalized apparel. As online retail flourishes and print-on-demand services gain traction, businesses are increasingly adopting DTF technology to meet the preferences of a modern clientele. This trend has prompted a rise in niche markets where customers seek specific design elements that traditional printing methods often struggle to accommodate.

With the rise of social media and digital marketing, customization has become a key selling point for brands. DTF transfers allow businesses to offer a vast array of design options without maintaining large inventories, thereby optimizing production and aligning with consumer preferences for unique, tailor-made fashion.

Quality Control in DTF Transfers

Ensuring quality in DTF transfers is paramount to customer satisfaction. After the transfer process is complete, each product must undergo a strict quality inspection to guarantee that the colors are vivid, and the details are precise. This step affirms that the final product meets the expectations of both the consumer and the brand, thereby bolstering the reputation of the print business.

Moreover, quality control also addresses the longevity of the prints on various fabric types. By implementing rigorous testing methods for durability, businesses can assure customers that their DTF products will not fade or deteriorate, reinforcing confidence in the custom apparel being offered.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a modern garment printing method where designs are first printed onto a special PET film. This film, coated with adhesive, is then heat-pressed onto fabrics. The process provides high-quality, vibrant prints that are durable and suited for custom apparel.

What are the advantages of using DTF printing technology for custom apparel?

DTF printing technology offers several advantages for custom apparel, including high resolution, vibrant color reproduction, and versatility across various fabric types. Additionally, DTF transfers can be produced in lower quantities, making it ideal for personalized designs and smaller orders without compromising quality.

How does the DTF printing process differ from other printing methods like DTG or screen printing?

Unlike DTG (Direct-to-Garment) printing, which prints directly onto the fabric, or screen printing, which requires stencils, DTF printing uses a film medium. This allows for more intricate designs and colors that adhere better to fabric, making it suitable for both light and dark garments.

What materials are suitable for DTF Transfers in custom apparel?

DTF Transfers can be applied to a wide range of materials including cotton, polyester, and blended fabrics. Understanding the fabric type is crucial, as different materials may require specific heat pressing times and temperatures for optimal results.

Are DTF Transfers a sustainable printing option?

Yes, DTF Transfers can be a sustainable printing option as recent developments in DTF technology include eco-friendly inks and films. This shift caters to the growing demand for sustainable practices in the custom apparel industry, reducing environmental impacts compared to traditional printing methods.

What advancements are being made in DTF technology for custom apparel printing?

DTF technology is advancing rapidly, with improvements in printing inks and machinery that enhance printing speeds and efficiency. New machinery is designed to be user-friendly, making DTF printing more accessible for businesses and enabling more sustainable printing options.

| Key Component | Description |

|---|---|

| Design Phase | Involves creating intricate designs using software like Adobe Illustrator and CorelDRAW, focusing on colors and resolution. |

| Printing Process | Designs are printed on coated PET film using DTF printers with CMYK inks and adhesive powders. |

| Curing | The printed film is heated to bond the ink and adhesive, essential for print longevity. |

| Transferring to Fabric | The film is pressed onto the fabric, transferring the design through heat, with variations in time and temperature needed based on the fabric type. |

| Final Inspection and Packaging | The final product undergoes quality checks for colors and details before packaging. |

Summary

DTF Transfers offer an innovative approach to custom garment printing, seamlessly merging high-quality design with efficient production processes. This method allows vibrant and durable prints to be transferred directly onto various fabrics after meticulous stages that include design creation, printing, curing, and heat transfer. As the market for personalized apparel continues to surge, fueled by advancements in eco-friendly technology and increased accessibility for businesses, DTF Transfers stand out as a reliable solution for meeting modern consumer demands. The balance of quality and efficiency ensures that DTF Transfers will remain at the forefront of the textile printing industry.