In the vibrant world of custom apparel printing, DTF transfers are leading the charge, introducing a new era of creativity and efficiency. This innovative Direct to Film (DTF) printing technology allows businesses to produce stunning designs with remarkable clarity and durability. By leveraging DTF transfer benefits, brands can offer high-quality prints on a diverse range of fabrics, catering to the growing demand for apparel customization. As more entrepreneurs and artists embrace this cutting-edge approach, the landscape of garment decoration is witnessing unprecedented transformations. Join us as we explore the exciting capabilities and market potential of DTF transfers, revealing how they are reshaping the future of custom apparel.

Direct to Film printing, commonly referred to by its acronym DTF, has become a game-changer in the field of apparel personalization. This technique streamlines the printing process, enabling sharper designs and diverse color palettes to be effortlessly transferred onto clothing. The advantages of utilizing DTF technology include not only the speed of production but also the quality that surpasses many traditional methods. With the rise in consumer interest for customized clothing options, this advance in printing provides a unique solution for businesses looking to stand out. Let’s delve into the multifaceted aspects of DTF and its implications for both small businesses and established apparel brands.

Understanding DTF Transfers: A New Era of Custom Apparel Printing

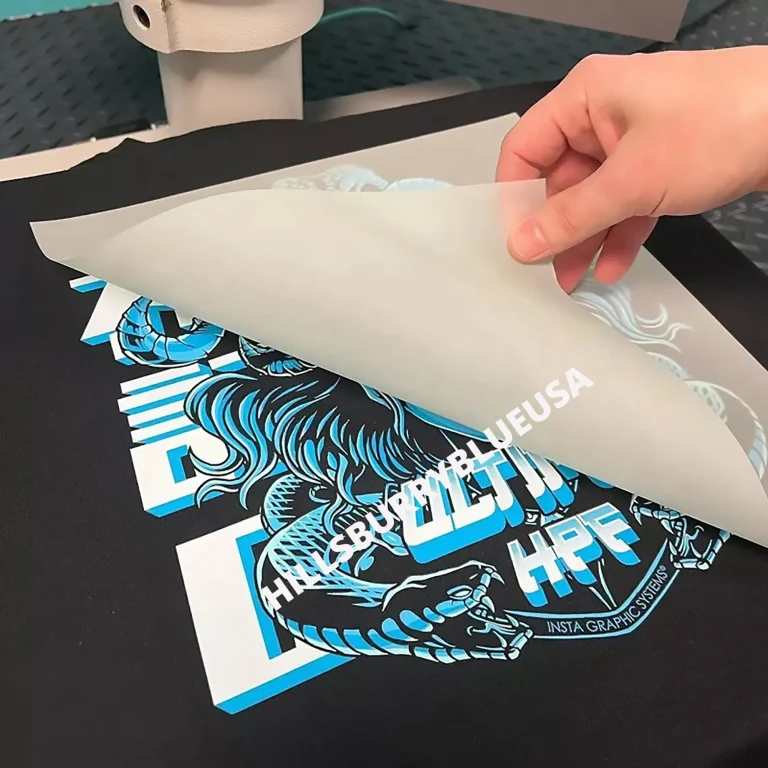

DTF Transfers, or Direct to Film transfers, mark a significant advancement in the realm of custom apparel printing. This innovative technology streamlines the process of creating intricate designs by transferring images directly onto a specially coated film, which is then applied to fabrics using heat. With the capabilities to print vibrant graphics on a wide range of materials such as cotton, polyester, and blends, DTF printing offers unparalleled versatility compared to traditional methods. Moreover, its use of water-based inks not only heightens the quality of the prints but also appeals to environmentally conscious brands seeking sustainable options.

The unique characteristics of DTF transfers make them an ideal choice for businesses aiming to stand out in the competitive landscape of custom apparel. By harnessing advanced printing technology, DTF allows for high-resolution designs that retain their integrity even after extensive washes. This durability, along with the ability to produce soft finishes that feel good on the skin, positions DTF as a favorable option for creating personalized apparel. As more brands recognize the potential of DTF Transfers, we can expect a notable shift toward this innovative printing technology in the custom apparel market.

The Unique Advantages of DTF Printing Technology

One of the most compelling benefits of DTF printing technology is its impressive quality and longevity. Unlike traditional screen printing methods that can lead to cracking and fading, DTF prints exhibit excellent durability. The advanced adhesion process ensures that designs are not just surface-deep but are absorbed into the fabric, creating a robust finish that withstands the test of time. This longevity is particularly advantageous for brands that prioritize quality, as their products maintain a fresh appearance even after many washes.

In addition to quality, DTF printing is budget-friendly, especially for small businesses or start-ups. The lower initial investments required to enter this printing method, compared to traditional screen printing or heat transfer vinyl, allow entrepreneurs to launch their custom apparel lines without the burden of high expenditures. As a result, businesses can experiment with a variety of designs and fabric types, enabling creative exploration without significant financial risk. Ultimately, the unique advantages of DTF printing technology are driving its popularity among custom apparel creators around the globe.

Exploring the Versatility of DTF Transfer Printing

DTF transfer printing demonstrates remarkable versatility, catering to a broad spectrum of fabric types. From lightweight sportswear to durable work apparel and trendy fashion garments, DTF technology adapts to diverse materials, providing seamless customization options for various markets. This flexibility not only allows businesses to expand their product lines but also helps them meet the specific demands of different customer segments with ease. As the trend for personalized apparel continues to rise, the ability to print on a wide range of textiles positions DTF printing as a go-to solution for custom designs.

Moreover, the application of DTF transfers enables businesses to respond rapidly to market trends and customer preferences. Unlike traditional printing methods requiring extensive setup, DTF allows for quick turnarounds on small orders without sacrificing quality. This capacity for rapid production is particularly beneficial in the realm of e-commerce, where consumers increasingly expect swift delivery of unique and customized products. As such, the versatility of DTF transfer printing not only enhances operational efficiency but also fosters customer satisfaction by meeting their needs promptly.

The Proliferating Market for DTF Printing Solutions

The market for DTF printing is experiencing a boom, projected to witness significant growth over the coming years. With an estimated compound annual growth rate (CAGR) exceeding 20%, it’s evident that businesses are beginning to recognize the efficiencies and capabilities inherent in DTF technology. According to market analyses, one of the key drivers behind this expansion is the increasing consumer demand for personalized apparel, pushing brands to seek innovative printing solutions that allow for greater customization.

Additionally, the rise of e-commerce has transformed the landscape for custom printing, with brands requiring quick, flexible solutions to satisfy their online customers. As online retail continues to scale, DTF printing stands out as a favorable technology that accommodates rapid production, making it an attractive option for businesses aiming to keep pace with ever-changing consumer demands. This evolving market underscores the need for businesses to adopt modern printing technologies like DTF transfers to stay competitive in the custom apparel sector.

Success Stories: DTF Transfers Empowering Small Businesses

Across the globe, numerous small businesses are capitalizing on the power of DTF transfers to carve out niches in the custom apparel landscape. For instance, a local athletic wear startup has harnessed DTF technology to produce customizable jerseys that resonate well with local sports teams. By offering intricate designs and quick turnaround times, the business has strategically positioned itself as a go-to source for high-quality athletic apparel in their community. This success story illustrates how DTF transfers enable small ventures to thrive against larger competitors by catering to specific market needs.

Moreover, creative entrepreneurs are launching unique merchandise lines using DTF printing, allowing their artistic visions to come to life without heavy initial investments. The flexibility that DTF technology provides not only permits them to experiment with various graphics but also enables them to refine their offerings based on real-time customer feedback. As a result, these success stories highlight the transformative impact of DTF transfers in empowering small businesses to innovate and succeed within the custom apparel industry.

The Future of Custom Apparel: DTF Printing Technology at the Forefront

As the custom apparel industry continues to evolve, DTF printing technology is emerging as a key player shaping its future. With its ability to offer high-quality, durable prints while minimizing production costs and turnaround times, DTF technology is positioned to meet the growing demand for personalization in fashion. The ability to adapt quickly to market trends is essential, and DTF transfers empower businesses to keep pace with ever-changing consumer preferences without sacrificing quality.

Looking ahead, the potential for DTF transfers within the realm of apparel customization appears boundless. As advancements in printing technology continue, we can anticipate even greater integration of DTF solutions across various sectors of the fashion industry. For companies aiming to remain relevant and competitive, embracing DTF printing can provide not only a competitive edge but also a pathway to explore creative design possibilities and enhance customer engagement in the coming years.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct to Film printing, is a revolutionary method in custom apparel printing. It involves printing high-quality designs onto a special film, which is then heat-pressed onto fabrics such as cotton and polyester. The process allows for vibrant colors and intricate designs, making it a versatile choice for various textile types.

What are the benefits of using DTF transfers in custom apparel printing?

DTF transfers offer multiple benefits, including exceptional print quality and durability, cost-effectiveness for small businesses, rapid production times, and versatility across fabric types. This makes them ideal for meeting diverse customer needs in the custom apparel market.

How does DTF printing technology differ from traditional printing methods?

Unlike traditional printing methods such as screen printing, DTF printing technology allows for direct printing of high-resolution images without the need for color separation. This results in quicker setup times, lower costs, and the ability to create complex designs easily.

Can DTF transfers be used on multiple fabric types in apparel customization?

Yes, DTF transfers are highly versatile and can be applied to various fabric types including cotton, polyester, and blends. This flexibility makes them suitable for different types of custom apparel, from sportswear to promotional items.

How has the growth of DTF printing impacted the custom apparel industry?

The growth of DTF printing technology has significantly transformed the custom apparel industry, with an expected CAGR of over 20%. This advancement has increased demand for personalized designs and faster production times, helping small businesses thrive in a competitive market.

Are DTF transfers environmentally friendly compared to other printing methods?

Yes, DTF transfers use water-based inks, making them a more environmentally friendly option compared to traditional printing methods. This eco-conscious approach appeals to businesses looking to reduce their environmental footprint while producing high-quality custom apparel.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers revolutionize custom apparel printing by offering speed, quality, and versatility. |

| What Are DTF Transfers? | A method where designs are printed on a special film and heat-pressed onto fabric, suitable for various textiles. |

| Technology Behind DTF Printing | Involves design creation, film printing, and heat transfer to bond designs on fabric. |

| Benefits of DTF Transfers | 1. Quality and Durability: Smooth, soft prints resistant to cracking. 2. Cost-Effectiveness: Lower upfront investment compared to traditional methods. 3. Rapid Production: Ideal for short runs and quick customization. 4. Versatility: Applicable to a variety of fabrics. |

| Market Growth of DTF Printing | Projected CAGR over 20%. Increased demand for customization and rise of e-commerce propel growth. |

| Success Stories: DTF in Action | Small businesses leverage DTF to create unique custom apparel, rapidly changing designs based on feedback. |

Summary

DTF Transfers are revolutionizing the custom apparel printing industry, providing unparalleled opportunities for businesses to enhance their product offerings and meet consumer demands. With high-quality, cost-effective, and versatile printing capabilities, DTF technology empowers entrepreneurs to create unique, personalized apparel faster and more efficiently than ever before. As the market continues to embrace this innovative method, DTF Transfers are set to play a pivotal role in shaping the future of fashion and custom merchandise.