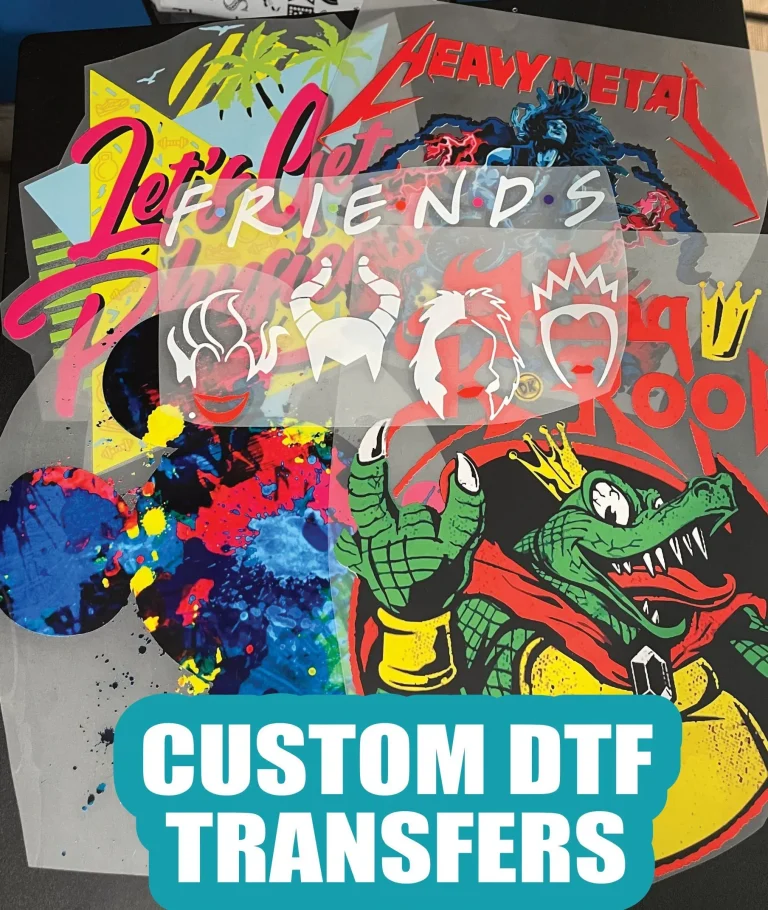

DTF Transfers, short for Direct-to-Film transfers, are redefining the landscape of custom apparel printing in exciting ways. This innovative technique allows businesses to produce high-quality designs that can be applied to a variety of fabrics with unmatched vibrancy. In today’s market, where personalization reigns supreme, leveraging DTF printing benefits can give your small business a competitive edge by offering size customization that meets the diverse needs of consumers. Not only do DTF transfers excel in creating standout visuals, but they also contribute to sustainability by reducing waste through tailored production processes. Join us as we dive into the numerous advantages of DTF technology and how it can elevate your branding and customer experience.

Direct-to-Film printing methods, commonly known as DTF transfers, have become pivotal in the realm of bespoke apparel decoration. This approach has made it possible for businesses to create unique and striking designs that cater to individual preferences, thereby enhancing customer satisfaction. With a focus on size customization, DTF processes allow companies to not only meet consumer demand but also foster brand loyalty and engagement. As the printing industry evolves, many small business printing solutions are now incorporating DTF technology, showcasing its importance in achieving high-quality and vivid print results. Let’s examine how embracing this transformative technology can open up new possibilities for your company.

The Evolution of DTF Transfers for Custom Apparel

Direct-to-Film (DTF) transfers have diversified the landscape of custom apparel printing, providing a dynamic solution for businesses looking to stand out. This innovative method allows for the creation of intricate designs that make use of vibrant inks capable of adhering to a range of fabrics. As technology advances, DTF transfers are becoming more refined and accessible, enabling businesses to offer personalized products that cater to individual consumer tastes.

Moreover, the application of DTF technology is proving crucial for small to medium-sized enterprises striving to compete in a crowded market. By using DTF transfers, businesses can implement effective marketing strategies that leverage the uniqueness of custom designs tailored to their customer base. This forward-thinking approach not only boosts brand visibility but also enhances customer loyalty, as clients appreciate tailored solutions that reflect their personal style.

Key Benefits of DTF Printing Technology

DTF printing presents numerous benefits that directly impact business performance. One primary advantage is its cost-effectiveness, allowing companies to produce high-quality garments without incurring significant operational costs. Businesses leveraging DTF printing can create economically priced custom apparel that resonates with clients, especially within niche markets. Additionally, the durability of DTF transfers means that products can withstand wear and tear, making them appealing to customers seeking longevity in their clothing.

Furthermore, the speed at which garments can be printed and delivered is a notable advantage for businesses. DTF printing enables quick turnaround times, which is vital for small businesses that need to respond swiftly to market demands and trends. The balance of efficiency and quality in DTF printing empowers businesses to maintain a competitive edge, driving sales through timely and attractive product offerings.

Custom Size Adaptability with DTF Transfers

One of the standout features of DTF transfers is their adaptability to size variations, allowing businesses to meet the ever-evolving expectations of consumers. In an age where personalization is key, businesses that embrace size customization can tailor their apparel offerings to fit specific customer needs. This not only enhances customer satisfaction but also fosters a stronger connection between consumers and brands.

Moreover, accommodating various sizes reduces fabric waste, a critical consideration in today’s environmentally conscious marketplace. By accurately predicting and producing popular sizes through DTF transfers, businesses can minimize surplus stock while maximizing their profits. This strategy leads to more sustainable practices, positioning the company as a responsible choice for eco-aware consumers.

Technical Innovations Driving DTF Printing Forward

Recent innovations in DTF printing technology have significantly broadened its application scope. Advancements in ink formulations and printer technologies have unlocked new possibilities for material compatibility and print quality. Leading brands, such as Epson and Roland, continue to push the boundaries of DTF capabilities, giving businesses access to a wider range of fabrics and enhanced color precision, which is essential for creating striking apparel designs.

As new models of DTF printers enter the market, the ease of operation and learning curve for employees have also improved. This technical evolution ensures that even small businesses can harness the power of DTF printing without extensive upfront investments or prolonged training periods. The increased accessibility of DTF technology makes it a feasible option for businesses looking to incorporate sophisticated printing solutions into their production processes.

Successful Case Studies in DTF Printing

The real-world application of DTF technology has resulted in several success stories that illustrate its potential benefits for various businesses. Companies that have adopted DTF printing have reported notably increased revenues, particularly those that focus on custom designs and size adaptability. A recent example involves a boutique apparel brand that utilized DTF transfers to create bespoke merchandise tailored to individual client preferences, resulting in a remarkable 40% growth in sales.

These success stories serve as a testament to the effectiveness of DTF technology in catering to specific market niches. As businesses learn to effectively market and showcase their unique offerings, they not only attract a wider audience but also foster a loyal customer base that values personalized experiences. These outcomes are encouraging for small businesses and provide a roadmap for those considering making a similar commitment to DTF printing.

Overcoming Challenges in DTF Printing Adoption

Despite the numerous benefits associated with DTF printing, businesses must also navigate several challenges before fully integrating the technology into their operations. One of the primary hurdles is the initial investment in DTF equipment, which can be significant for smaller enterprises. Additionally, businesses need to budget for training sessions to ensure that staff members are well-equipped to manage new printing processes and machinery.

Beyond financial considerations, there is also a need for ongoing support and resources to maintain quality control. New users may face a steep learning curve, requiring companies to invest time and energy into mastering both the hardware and software associated with DTF printing. However, with the right training and technical resources, businesses can overcome these obstacles, leading to a fruitful integration of DTF technology into their custom printing solutions.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a revolutionary method of custom apparel printing that involves applying high-quality ink onto a special film which is then transferred to fabric using heat and pressure. This process allows businesses to create vibrant, long-lasting designs that are perfect for various textile materials.

What are the benefits of using DTF printing technologies for small business printing solutions?

The benefits of DTF printing technologies include cost-effectiveness, high-quality results, and the ability to easily customize sizes. This makes DTF a versatile choice for small business printing solutions looking to offer personalized products while maintaining production efficiency.

How does size customization factor into DTF Transfers for apparel?

Size customization is one of the key advantages of DTF transfers. Businesses can create specific designs tailored to individual size requirements, reducing waste and enhancing customer satisfaction, as consumers increasingly seek products that fit their unique dimensions.

What are some recent advancements in DTF printing technology?

Recent advancements in DTF printing technology encompass improved ink formulations and the introduction of specialized printers from brands like Epson and Roland. These innovations enhance fabric compatibility and color accuracy, allowing for even greater creativity in custom apparel design.

Why should businesses consider DTF Transfers over traditional printing methods?

Businesses should consider DTF transfers over traditional printing methods due to the vibrant quality of prints, the efficiency of production, and the flexibility in customization. DTF technology allows for designs that cater particularly well to size variations, giving businesses a competitive edge in the market.

How can DTF printing help reduce waste in garment production?

DTF printing helps reduce waste in garment production by enabling businesses to produce garments based on specific customer size demands. This tailored approach minimizes excess inventory and ensures that production aligns closely with market needs, contributing to a more sustainable business model.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers revolutionize customization in apparel by meeting consumer preferences. |

| Understanding DTF Transfers | A method that allows for vibrant, durable prints on various fabrics, enhancing high-quality garment decoration. |

| Market Growth and Adoption | DTF printing is experiencing significant growth, becoming popular in apparel due to its cost-effectiveness and aesthetic quality. |

| Customization by Size | DTF allows businesses to create unique designs tailored to individual sizes, improving customer engagement and reducing waste. |

| Technical Innovations | Advancements in DTF technology expand the range of materials and enhance color precision. |

| Challenges and Considerations | Businesses must manage upfront equipment costs and ensure understanding of DTF technology for quality control. |

| Importance of Size Adaptability | Accommodating size preferences in DTF transfers enhances customer loyalty and reduces waste. |

| Conclusion | DTF transfers offer substantial opportunities for business growth through size-focused customization despite initial challenges. |

Summary

DTF Transfers play a pivotal role in the customization landscape for businesses looking to enhance their offerings. As the trend of personalized apparel continues to grow, DTF transfers allow companies to cater specifically to the size and preferences of their consumers, ensuring higher satisfaction and loyalty. By investing in this technology, businesses can decrease waste while increasing their competitive edge. Additionally, the technical innovations within DTF transfers mean that quality can be consistently maintained across various fabrics. Overall, embracing DTF transfers for customization will not only streamline production processes but also fulfill the demand for unique, size-specific apparel, driving business success.