DTF Transfers, or Direct-to-Film Transfers, have emerged as a groundbreaking solution in the world of garment printing, offering creative enthusiasts and businesses a revolutionary way to create custom apparel. By utilizing advanced technology, DTF transfers produce ultra-vibrant designs that not only stand out but also maintain their integrity after countless washes. This method of printing has redefined the norms of custom clothing, making it easier than ever to bring personalized visions into reality. Moreover, as sustainability becomes a priority for consumers, DTF transfers offer eco-friendly printing options that appeal to the environmentally conscious shopper. Dive into the innovative realm of DTF transfers and discover how they are reshaping the landscape of customizable products.

In the realm of fabric decoration, techniques such as Direct-to-Film transfers are leading the charge in delivering colorful and durable prints. Known for their sharp and vivid imagery, these innovative methods allow artists and creators to visualize their designs on various textiles, resulting in endless customization possibilities. As trends shift towards unique and personalized fashion, processes like DTF printing continue to elevate the landscape of custom apparel, attracting eco-aware consumers with their sustainable practices. This efficient method not only caters to diverse fabric types but also ensures that stunning patterns can be easily achieved at scale. Embrace the future of textile printing with these versatile solutions that prioritize creativity and eco-friendliness.

Introduction to DTF Transfers: What You Need to Know

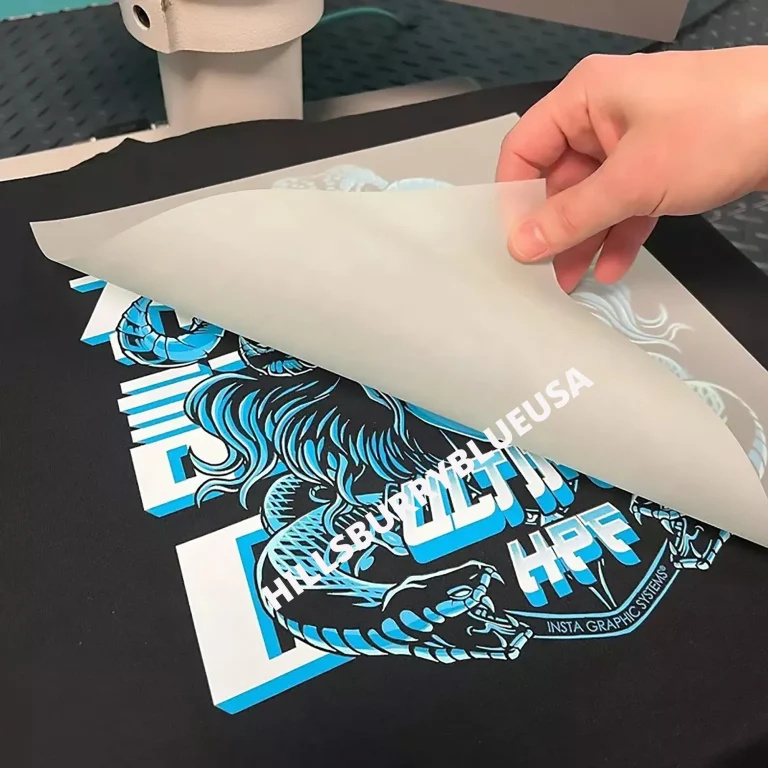

Direct-to-Film (DTF) transfers are changing the landscape of garment printing by offering a technology that combines ease of use with stunning results. This innovative method allows for the application of intricate, high-quality designs onto fabrics with remarkable vibrancy. Unlike traditional methods that can overshadow detail, DTF printing is capable of producing designs that pop with color and depth, capturing the artistic vision of a designer beautifully in every transfer.

In essence, DTF transfers operate by utilizing a special film that is printed upon and then heat pressed onto chosen fabrics. The result is a long-lasting, washable product that maintains its integrity even after numerous laundry cycles. This technology not only meets the demands of consumers seeking custom apparel but also caters to businesses aspiring to stand out in a saturated market by providing unique, high-quality product offerings.

Unmatched Quality with DTF Transfers

The quality of DTF transfers is one of the most compelling reasons for their rising popularity. With advancements in printing technology, DTF is now capable of achieving detail and color accuracy that was previously unattainable with other printing methods. Customers can expect vibrant designs that don’t fade or peel, ensuring that the apparel they love remains as stunning as the day they bought it.

Moreover, the durability of these transfers means that items printed using DTF methods can withstand the rigors of everyday wear. This is particularly important for consumers who want custom apparel that can keep up with their active lifestyles. The superior quality of DTF transfers translates not just to aesthetics, but also to longevity, making them a smart choice for anyone looking to invest in lasting garments.

The Versatility of DTF Transfer Technology

One of the standout features of DTF transfers is their versatility when it comes to material compatibility. Whether you are working with cotton, polyester, or blends, DTF technology allows for a diverse range of fabrics to be utilized in the printing process. This capability has opened new doors for custom apparel businesses, enabling them to cater to varied market demands while keeping production affordable.

In addition, DTF transfers excel in producing designs that incorporate multiple colors without compromising on finish quality. This versatility means that brands can unleash their creativity by printing everything from simple logos to complex artwork without worrying about the limitations that come with traditional methods. As a result, businesses can offer tailored solutions to their clientele, enhancing customer satisfaction and brand loyalty.

Eco-Friendly Practices in DTF Printing

As sustainability becomes increasingly important in consumers’ purchasing decisions, DTF transfers have emerged as a more environmentally responsible option within the custom apparel industry. Print shops are now utilizing eco-friendly inks and adhesives, significantly reducing their carbon footprint compared to traditional screen printing methods. This transition not only addresses consumer concerns regarding environmental impact but also positions businesses as conscious players in the textile market.

Furthermore, advancements in ink formulation used in DTF printing lead to less water and energy consumption during the printing process. Eco-friendly production not only appeals to a growing base of environmentally aware consumers but also aligns with industry trends towards responsible practices. As a business, embracing DTF technology is not just about providing beautiful designs, but also about supporting a sustainable future.

DTF Transfers: The Future of Custom Apparel

The future of custom apparel is brightly colored with the introduction of DTF transfers into the mainstream market. As consumer preferences shift toward personalization, brands that adopt DTF technology stand to capture a significant share of this burgeoning market. The seamless integration of advanced printing techniques with accessible pricing structures means that even small businesses can now compete effectively in an otherwise challenging landscape.

Additionally, the customization potential offered by DTF transfers allows businesses to stay ahead of fashion trends. With rapid response capabilities, companies can quickly adapt their offerings to meet consumer demands, creating unique garments that reflect individual styles. This adaptability not only fosters creativity but also increases customer engagement, making DTF a valuable tool for any brand looking to thrive in today’s competitive custom apparel market.

Navigating Market Trends with DTF Technology

The DTF transfer market is witnessing substantial growth, driven by a surge in demand for unique apparel solutions. Brands are increasingly recognizing the imperative to differentiate themselves through customization, leading to greater investment in technologies like DTF that allow for a high degree of design flexibility. As a result, businesses equipped with DTF printing capabilities can cater to an evolving consumer landscape that prioritizes individuality.

Moreover, the trend towards personalization in fashion is reshaping the DTF transfer market by encouraging innovations in design offerings. As creative professionals look to push boundaries, DTF technology will likely play a pivotal role in enabling intricate patterns, vibrant colors, and personalized creations that align with consumer desires. Embracing these trends will not only enhance product portfolios but also help brands build meaningful connections with their audience.

Frequently Asked Questions

What are DTF Transfers and how do they work for custom apparel?

DTF Transfers, or Direct-to-Film Transfers, are a modern garment printing technology that prints vivid designs onto a film, which is then applied to fabric using heat. This process produces high-resolution, vibrant designs that adhere well to various materials, making them ideal for custom apparel.

Why are DTF Transfers known for their vibrant designs?

DTF Transfers are celebrated for their unmatched vibrancy due to high-quality ink and advanced printing technology. This method allows a broader color palette and finer detail in designs, ensuring that colors remain intense and vibrant even after multiple washes.

How do DTF Transfers differ from traditional garment printing methods?

Unlike traditional methods like screen printing, DTF Transfers utilize a film coated with heat-activated adhesive, which allows for more intricate designs, greater color vibrancy, and compatibility with various fabric types. This results in durable designs that can withstand regular wear.

Are DTF Transfers eco-friendly for sustainable printing?

Yes, many DTF Transfers utilize eco-friendly inks and materials, aligning with sustainability trends in printing. This focus on environmentally conscious practices helps reduce the ecological footprint associated with custom apparel production.

What are the advantages of using DTF Transfers for small businesses?

DTF Transfers are particularly advantageous for small businesses due to their cost-effectiveness. The lower startup costs and the ability to produce vibrant designs on demand make it easier for entrepreneurs to enter the custom apparel market without significant financial barriers.

Can DTF Transfers be used on different fabric types?

Absolutely! DTF Transfers are versatile and can be applied to various materials, including cotton, polyester, and blends. This flexibility enables businesses to create a diverse product range and appeal to a wider audience.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing method that transfers high-resolution designs onto fabrics using a special film and heat-activated adhesive. |

| Advantages | 1. Unmatched vibrancy and color integrity after washes. 2. Durable design that withstands everyday wear. 3. Compatibility with multiple fabrics including cotton and polyester. 4. Cost-effective for small businesses entering custom apparel market. 5. Eco-friendly options available reducing environmental impact. |

| Recent Developments | Advancements improving adhesive technology, fine printing techniques, and sustainability in ink manufacturing processes. |

| Market Trends | Growing consumer demand for customization in fashion, making DTF transfers essential for businesses today. |

Summary

DTF Transfers represent a revolutionary method for creating vibrant, long-lasting designs that cater to the evolving needs of the apparel market. With their ability to maintain color integrity and durability, these transfers make it easier than ever for businesses and consumers to express their personal style through custom apparel. The growing trend of personalization in fashion means that DTF Transfers are not just a passing phase but a solution that’s here to stay, aligning perfectly with the modern consumer’s desire for unique and sustainable products. As the industry continues to innovate, those who embrace DTF technology will find themselves at the forefront of a dynamic market that values creativity, quality, and environmental responsibility.