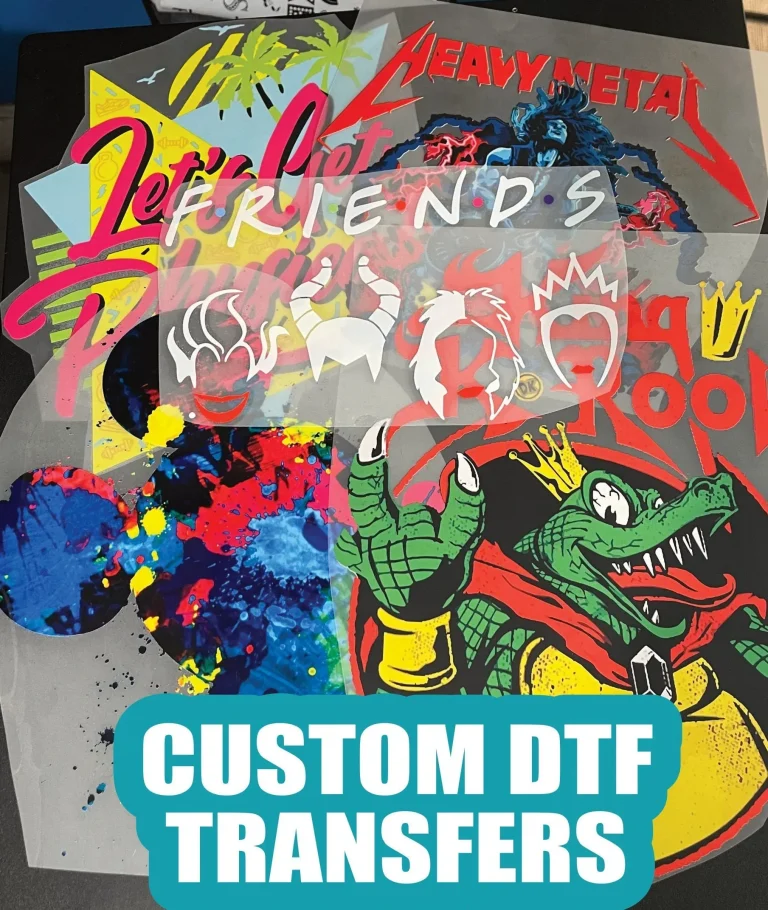

DTF transfers, short for Direct-to-Film transfers, have emerged as a revolutionary technique in the realm of custom apparel printing. This cutting-edge printing technology empowers designers and entrepreneurs by enabling the production of stunning, high-quality prints on a wide variety of materials. With an unparalleled ability to deliver intricate designs and vibrant colors, DTF printing benefits both small businesses and seasoned professionals alike. This introductory guide aims to explore the DTF printing process, highlight its numerous advantages, and provide essential tips for beginners looking to harness its full potential. Get ready to unlock a world of creative possibilities with DTF transfers, where innovation meets fashion.

In recent years, a new method has gained traction among apparel printers—Direct-to-Film printing. This technique, often simply referred to as DTF printing, harnesses the power of specialized films and thermal transfer processes to create striking designs that adhere well to fabrics. Unlike traditional methods such as screen printing or direct-to-garment printing, DTF provides a versatile solution for producing custom designs across various materials. Whether you’re a hobbyist or a business owner, understanding the benefits and processes of this innovative technology can significantly enhance your printing projects. Join us as we delve into the unique aspects of DTF printing and discover how you can get started.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process is revolutionizing how designs are transferred onto fabrics. It begins with the creation of an image in graphic design software, followed by printing this design onto a special DTF film using a compatible printer. This film acts as a bridge between the printer and the fabric, ensuring that vibrant colors and intricate designs can be accurately transferred to various materials. Unlike other printing methods, the application adheres to the substrate through an adhesive powder that is heat-activated during the transfer process, which significantly enhances the adhesion and durability of the print.

Once you’ve printed your design onto the DTF film, the next step is to apply a hot melt adhesive powder. This crucial element bonds the ink to the fabric when heat is applied. After curing the adhesive, the film is then placed on the fabric using a heat press. The heat press ensures that the design adheres perfectly, allowing for a smooth transfer without any cracks or peeling. This step-by-step approach not only simplifies the workflow but also guarantees high-quality outputs that are durable and wash-resistant.

Benefits of DTF Printing for Custom Apparel

DTF printing streamlines the process of creating custom apparel, offering several benefits that set it apart from traditional methods. One major advantage is its compatibility with different fabric types, including cotton, polyester, and blends. This versatility allows businesses to cater to a diverse clientele, producing everything from t-shirts and sweatshirts to bags and home décor. Moreover, the high-quality prints produced through DTF technology exhibit exceptional detail and color vibrancy, making them favorites among customers and designers alike.

Aside from versatility, DTF printing also boasts remarkable durability. The prints are designed to withstand multiple washes without fading or cracking, ensuring that customers receive products that maintain their aesthetic for longer periods. This longevity not only enhances customer satisfaction but also reduces returns and complaints for businesses. By leveraging the benefits of DTF printing, entrepreneurs can provide high-quality, customized apparel that satisfies market demands, ultimately leading to increased sales and customer loyalty.

Getting Started with Your DTF Transfer Business

For beginners looking to start a DTF transfer business, understanding the essential equipment needed is crucial. Investing in a quality DTF printer is the first step. These specialized printers are designed for optimal performance with DTF films and ensure vibrant prints that stand out. Additionally, a reliable heat press is vital as it guarantees proper transfer of designs to fabrics, which is paramount for achieving high-quality results. Other necessary tools include hot melt adhesive powder and DTF transfer films, both integral to the printing process.

Once you have the equipment sorted, it’s important to familiarize yourself with the DTF printing process step-by-step. This involves not just printing, but also the application of adhesive and curing techniques that are fundamental to the success of your prints. As a beginner, consider leveraging online resources such as instructional videos and community forums to gather tips and advice. Engaging with other enthusiasts can provide insights and help you avoid common pitfalls, making your journey into the world of DTF transfers more manageable and enjoyable.

Innovations in DTF Printing Technology

The world of DTF printing is continuously evolving, with modern innovations greatly enhancing the printing process. Newer DTF printers come equipped with advanced features such as automatic feeding systems and faster printing capabilities. These innovations drastically reduce production time while improving print quality. Furthermore, advancements in ink formulations and transfer films have led to even better adhesion and color reproduction, making contemporary DTF prints highly competitive in the print market.

Additionally, machine innovations contribute to the sustainability aspect of DTF printing. Many companies are now producing eco-friendly inks and transfer materials that align with environmental standards. This shift not only attracts health-conscious consumers but also positions businesses as environmentally responsible, a growing expectation in today’s marketplace. By incorporating these innovations into your DTF printing practice, you can remain ahead in a competitive landscape, catering to both quality and eco-conscious clients.

DTF Printing vs. Other Apparel Printing Techniques

When comparing DTF printing to other techniques such as Direct-to-Garment (DTG) and traditional screen printing, a few distinct differences emerge. DTF printing stands out due to its unique process that allows for greater detail in designs and a wider variety of fabric compatibility. While DTG printing excels with organic cotton fabrics, it may struggle with synthetic materials, limiting design possibilities. Conversely, DTF transfers can be applied to almost any material, giving businesses a broader range of options to satisfy their customers.

Additionally, when it comes to durability, DTF prints demonstrate more resilience than traditional screen prints. Screen-printed designs may crack or fade over time, particularly after numerous washes; however, DTF transfers are engineered to withstand frequent laundering without deterioration. This durability makes DTF an ideal option for custom apparel businesses aiming to provide high-quality products for customers seeking longevity in their purchases.

Resources for Mastering DTF Printing

For those venturing into the DTF printing world, numerous resources can enhance the learning curve. Online platforms such as forums and social media groups focused on DTF printing are invaluable. They offer a space for networking with other printers, exchanging ideas, troubleshooting issues, and sharing success stories. Engaging in these communities can provide beginners with a wealth of knowledge that is not easily found in standard tutorials or guides.

Moreover, taking advantage of online courses and YouTube tutorials tailored to DTF printing can significantly improve your skill set. These resources often provide step-by-step instructions and practical tips from experienced practitioners, making the learning process more practical and relatable. Additionally, comprehensive guides on DTF printing techniques can serve as reference materials, providing ongoing support as you refine your business operations.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film, applying an adhesive layer, and using heat to transfer the design onto fabric. This process allows for vibrant, high-quality prints that adhere well to various materials, making it ideal for custom apparel.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers several benefits for custom apparel, including versatility with different fabric types, durability against fading and cracking, and ease of use for beginners. This printing method allows for high-quality, lasting designs that cater to a wide range of customer preferences.

What equipment do I need to start DTF printing?

To begin DTF printing, you will need a specialized DTF printer, hot melt adhesive powder, a heat press, and DTF transfer film. These essential tools are vital for creating high-quality transfers that adhere well to fabrics.

Can beginners easily learn the DTF printing process?

Yes, beginners can easily learn the DTF printing process due to its user-friendly nature. With fewer technical requirements compared to traditional screen printing, aspiring entrepreneurs can find many online resources, forums, and tutorial videos to help them get started.

How does the DTF printing process compare to other printing techniques?

DTF printing stands out compared to other techniques like DTG and screen printing due to its versatility, the ability to print on various fabric types, and the creation of vibrant, durable designs. DTF transfers are also easier to use and set up, making them ideal for beginners and small businesses.

What recent developments have improved the DTF printing process?

Recent developments in DTF printing include advancements in printer technology, the introduction of eco-friendly inks, and improved heat transfer systems. These innovations enhance print quality, speed up production, and reduce the ecological footprint of DTF printing, making it more attractive for businesses.

| Key Points | Details |

|---|---|

| Overview of DTF Transfers | DTF transfers print on special film, using adhesive and heat to transfer designs to various fabrics. |

| Key Advantages | Versatility: Applicable on different materials (cotton, polyester, stretchy fabrics). Durability: Resists fading and cracking, maintains vibrancy after washes. Ease of Use: Requires less complex equipment, ideal for beginners. |

| Recent Developments | Updates in techniques, innovations in DTF printers, and eco-friendly solutions improving the industry. |

| Getting Started | Essential equipment needed: DTF printer, hot melt adhesive powder, heat press, DTF transfer film. Step-by-step process outlined for beginners. |

| Resources for Beginners | Online forums, workshops, YouTube tutorials, and comprehensive guides available to assist in learning. |

Summary

DTF Transfers are revolutionizing the custom printing landscape, offering vibrant and durable designs on a variety of materials. This advanced printing method not only caters to diverse customer needs through its versatility, but it also ensures that prints remain long-lasting and resistant to fading. As technology continues to evolve within the field, beginners and seasoned professionals alike are presented with new opportunities to enhance their creations. By mastering DTF transfers, one can harness the full potential of this innovative technique, paving the way for success in the competitive landscape of custom apparel.