In the world of textile printing, DTF Transfers—short for Direct-to-Film Transfers—have rapidly emerged as a revolutionary printing technique, reshaping how intricate designs are applied to fabrics. Utilizing the DTF printing process, this method allows for vibrant color reproduction and exceptional detail, making it increasingly popular among apparel brands and decorators alike. The advantages of DTF transfers include their remarkable durability and versatility across a variety of fabrics, which opens up limitless opportunities for creativity in garment production. As the DTF transfer market expands, more businesses are discovering the benefits of best DTF printers, leading to an increased demand for this innovative technology. By understanding the various facets of DTF transfers, you can unlock new potentials in your printing endeavors and stand out in this competitive industry.

When discussing modern printing techniques, the term “Direct-to-Film printing” emerges prominently, offering businesses a fresh and effective approach to apply vivid designs on diverse textiles. This innovative printing methodology efficiently transfers high-resolution artwork onto fabric, setting it apart from older techniques like screen printing. The DTF printing process is gaining traction for its unique benefits, such as colorful durability and ease of use, appealing to both seasoned printers and newcomers. Notably, the demand for DTF transfers continues to grow, creating opportunities for brands to innovate their product lines and meet customer preferences. Embracing this advanced printing solution not only enhances creative possibilities but also supports the evolving expectations of eco-conscious consumers.

What You Need to Know About DTF Transfers

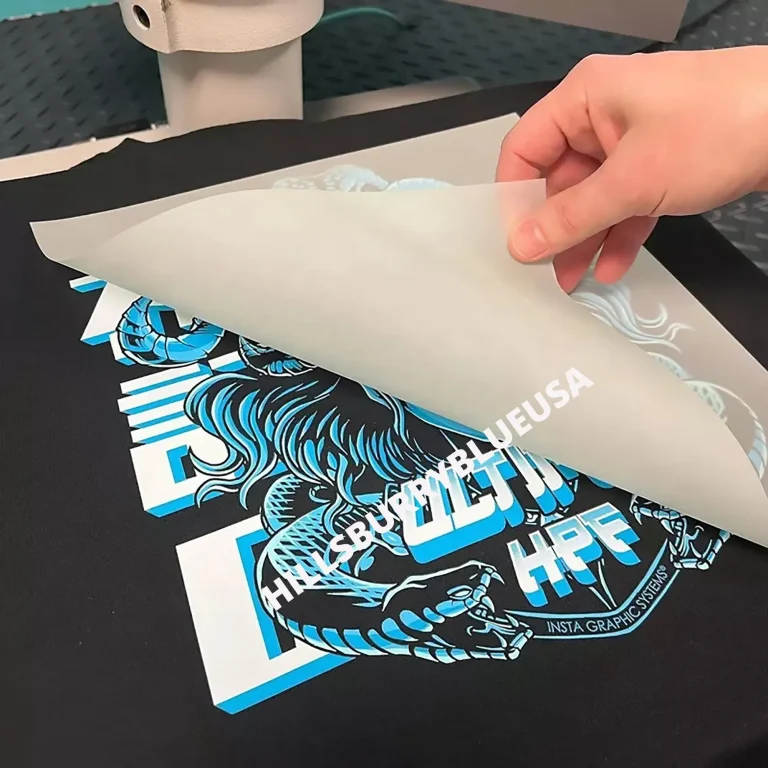

DTF transfers, or Direct-to-Film transfers, represent a significant innovation within the textile printing industry. This method involves printing high-resolution designs directly onto a specialized film using durable DTF inks. Once printed, this film undergoes an adhesive application, where a powder-like substance is spread over the design to ensure proper adherence when heat-pressed onto fabric. The complete DTF printing process not only allows for precise and vibrant color reproduction but also provides the flexibility needed to print on various materials like cotton, polyester, and even blends.

Understanding the nuances of DTF transfers is crucial for businesses wishing to incorporate this technology into their offerings. As compared to more traditional printing methods such as screen printing, the DTF process enables quick turnaround times for custom designs, making it ideal for print-on-demand services. Moreover, the inks used in DTF printing are engineered to produce bold colors and intricate designs, enhancing the visual appeal of apparel and other textile products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a specialized film followed by applying an adhesive powder. Heat and pressure are then used to transfer the print onto a textile surface, creating vibrant and durable designs.

What are the advantages of DTF transfers compared to traditional printing methods?

The advantages of DTF transfers include exceptional durability, vibrant color reproduction, compatibility with a variety of fabrics, and eco-friendly options. These benefits make DTF printing a preferred choice for many apparel businesses.

How does the DTF printing process differ from other printing techniques?

The DTF printing process is distinct as it prints onto a film first, enhancing color vibrancy and detail. Unlike screen printing or heat transfer vinyl, DTF can handle intricate designs and offers better adhesion and longevity on various fabric types.

What are some of the best DTF printers available in the market?

Some of the best DTF printers include offerings from brands like Epson and Roland, known for their reliability and quality in producing high-resolution DTF transfers. Choosing a reliable printer is key for achieving the best results in DTF printing.

Why is the DTF transfer market growing rapidly?

The DTF transfer market is expanding due to its cost-effectiveness, efficiency for short-run printing, and increasing demand for high-quality custom apparel. This growth is further fueled by advancements in DTF printing technology that enhance ease of use for businesses.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and blends. This versatility makes DTF an excellent choice for businesses looking to offer diverse textile products.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A method of printing designs onto a specialized film with high-quality inks, using powder adhesive and heat to transfer onto fabrics. |

| Advantages of DTF Transfers | 1. Durability: Long-lasting, resistant to fading and cracking. 2. Color Vibrancy: Excels in color reproduction and detail. 3. Material Compatibility: Works on diverse fabrics. 4. Eco-friendly Options: Many inks and materials are environmentally friendly. |

| Market Trends | Rapid growth in adoption for cost-effectiveness and efficiency. Expected continued trend in 2024. Small businesses are coming on board due to accessible technology and lower costs. |

| DTF Transfer Process | 1. Design Creation 2. Printing on PET Film 3. Applying Adhesive 4. Curing the Adhesive 5. Heat Pressing to Garment |

Summary

DTF transfers are at the forefront of modern textile printing, offering a revolutionary way to create vibrant and durable designs on fabrics. As businesses increasingly adopt this innovative technique, they gain access to enhanced creative possibilities and superior print quality that traditional methods often can’t match. This guide not only demystifies the DTF process but also highlights its numerous benefits, including impressive durability and versatility across various materials. For anyone looking to elevate their printing projects, understanding and utilizing DTF transfers will undoubtedly unlock new avenues for success in the dynamic printing industry.