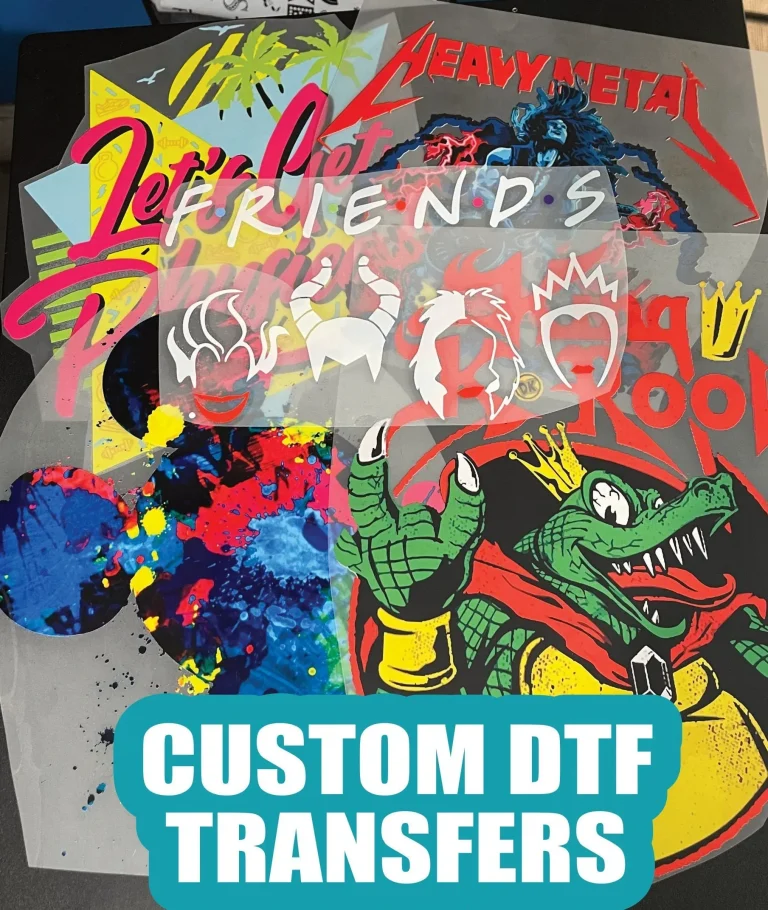

DTF transfers, or Direct-to-Film transfers, represent a significant advancement in printing technology for custom apparel. Unlike traditional printing methods such as screen printing and direct-to-garment (DTG) printing, DTF transfers allow for high-quality, vibrant images to be printed on a wide range of fabric types. This new technique is quickly gaining traction among businesses and individual crafters alike, thanks to its ability to deliver fast results without sacrificing durability or color quality. As the apparel industry continues to embrace innovative solutions, DTF transfers are emerging as a popular alternative to more conventional methods. In this article, we will delve into the advantages and applications of DTF printing, comparing it with traditional options to highlight its growing importance in the custom printing landscape.

Often referred to as Direct-to-Film printing, DTF transfers offer an innovative solution for custom garment decoration, marking a shift from older techniques. This printing method simplifies the process of creating designs, eliminating the complexities associated with traditional practices like screen printing and DTG methods. With their capacity for producing high-quality designs and accommodating various fabric types, DTF transfers are becoming a go-to choice for both small entrepreneurs and larger apparel brands. The efficiency and effectiveness of DTF technology bring it to the forefront of modern printing discussions, making it essential to understand its unique benefits as the custom apparel market evolves. By examining DTF alongside its traditional counterparts, we can appreciate the strides being made in printing technology and its implications for creative expression in fashion.

The Evolution of Printing Technology in Custom Apparel

Printing technology has undergone remarkable changes over the decades, leading to innovative methods that cater specifically to custom apparel needs. Traditional printing methods such as screen printing and direct-to-garment (DTG) have been staples in the industry for years. Screen printing, known for its vibrant colors and durable designs, is often the go-to for bulk orders. However, it requires extensive setup time and is less adaptable for small batches, which can be a limitation for today’s fast-paced market. On the other hand, direct-to-garment printing offers flexibility and precision but often falls short in terms of speed and cost management when dealing with large runs.

With the introduction of DTF transfers, the landscape of custom printing is witnessing a transformative shift. This method combines the best features of traditional processes while addressing their shortcomings. DTF transfers allow for exceptional print quality, vivid colors, and intricate designs without the constraints associated with the setup and application of traditional methods. As we witness these advancements, it’s clear that adapting to technological trends is essential for businesses aiming to stay competitive.

Understanding DTF Transfers: Benefits Over Traditional Methods

DTF transfers stand out as a modern solution with numerous advantages over traditional methods, making them particularly attractive to businesses focused on custom apparel. One of the primary benefits is the ease with which DTF prints can be applied to a range of fabric types. Unlike screen printing, which may be limited in terms of fabric compatibility, DTF transfers can effectively adhere to cotton, polyester, and blends, broadening the potential for creative designs. Furthermore, the resolution achieved through DTF technology is notably higher, resulting in crisp and vibrant images that are vital in the competitive world of custom printing.

Another significant advantage is the cost-effectiveness DTF transfers offer for small production runs. Traditional methods often entail high setup costs and are inefficient for small orders, making them less feasible for emerging brands or individual entrepreneurs. DTF technology, by contrast, requires fewer resources and allows for quick project initiation, enabling businesses to respond swiftly to market demands without incurring excessive costs. This balance of cost and quality makes DTF an appealing choice.

Speed and Efficiency: DTF Transfers vs. Traditional Printing

In today’s dynamic market, speed and efficiency are crucial components of successful printing operations. DTF transfers excel in this aspect, significantly reducing the time from design to final product. With traditional screen printing, the process can be lengthy, involving multiple stages and meticulous color separations, which can delay projects. Conversely, DTF technology streamlines this workflow, allowing for rapid production times. This efficiency becomes increasingly important for businesses looking to cater to fast-moving trends in the custom apparel sector.

The ability to fulfill customer orders quickly not only enhances satisfaction but also boosts a company’s reputation in an industry where speed is increasingly becoming synonymous with quality. For small businesses and individual crafters, this affordability and efficiency of DTF transfers can lead to greater flexibility in fulfilling orders without sacrificing quality. As brands continue to recognize the need for rapid output, DTF printing stands tall as a standout option, paving the way for more responsive production strategies.

Durability and Quality: Longevity of DTF Transfers

Durability is a key factor that influences the choice of printing methods for custom apparel. DTF transfers offer remarkable resilience compared to traditional printing methods, ensuring prints withstand the test of time. Unlike screen printing, where thick inks may crack or fade after multiple washes, DTF prints retain their vibrancy and integrity over extended periods. This durability appeals not just to businesses but also to consumers who prioritize quality in apparel, driving them to seek out options that deliver lasting results.

Additionally, the soft hand feel of DTF prints enhances wearability, catering to customers’ desires for comfort in their clothing. This aspect is especially beneficial for brands that focus on premium apparel, where fabric feel can significantly impact consumer satisfaction. Overall, the combination of durability and comfort places DTF transfers in a competitive position, increasingly favored for high-quality custom apparel.

The Future of DTF Transfers and Their Impact on Custom Printing

The future of printing technology is undoubtedly leaning towards DTF transfers as they continue to rise in popularity within the custom printing landscape. As consumer demands evolve, so does the necessity for printing methods that offer flexibility, quality, and efficiency. The ability for DTF transfers to accommodate quick changes without sacrificing quality positions them as a frontrunner in the printing industry. This trend suggests a shift toward more agile production processes that align with modern consumer expectations.

Furthermore, innovations surrounding DTF printers are set to enhance their capabilities even further. As technology advances, businesses will likely see improvements in print speed, quality, and material compatibility. With the continual development of DTF printing methods, the impact on the custom apparel market will be profound, transforming how brands approach manufacturing and design strategies. Understanding these shifts will be crucial for stakeholders aiming to harness the benefits of DTF printing.

Embracing DTF Transfers for Small Businesses and Entrepreneurs

For small businesses and entrepreneurial ventures, embracing DTF transfers can serve as a strategic decision in a competitive market. The lower upfront investment and reduced setup time allow new players to enter the custom printing arena without significant financial barriers. This accessibility enables a broader range of creators to explore their artistic visions without the constraints typical of traditional methods. As a result, budding entrepreneurs can showcase their unique designs effectively and efficiently.

Moreover, the versatility of DTF transfers encourages experimentation with different materials and styles, propelling innovation in product offerings. By utilizing DTF printing, small businesses can diversify their product lines and respond to niche markets that were previously challenging to penetrate. In this way, DTF transfers not only provide practical printing solutions but also empower a new generation of creators to thrive in the custom apparel industry.

Frequently Asked Questions

What are DTF transfers compared to traditional printing methods like screen printing?

DTF transfers, or direct-to-film transfers, offer several advantages over traditional printing methods such as screen printing. DTF printing requires less setup time and allows for vibrant, high-quality prints on various fabric types, which can often be stiffer with screen printing. This innovation makes DTF a popular choice for custom apparel, allowing businesses to produce smaller batches efficiently.

How does DTF printing technology improve upon direct-to-garment (DTG) printing?

While both DTF and direct-to-garment (DTG) printing produce high-quality images, DTF printing technology allows for faster production with less setup required. DTF can be used on different fabric types without the need for special treatment, making it more versatile for varied custom apparel needs. Additionally, DTF offers better cost efficiency, especially for small runs.

Can DTF transfers be used on various fabric types unlike traditional methods?

Yes, DTF transfers are highly versatile and can be applied to a wide array of fabric types, ranging from cotton to blends and synthetics. This versatility gives DTF printing an edge over some traditional methods, which may have material restrictions. As a result, DTF is increasingly favored in the custom apparel industry.

What are the main advantages of DTF transfers for custom apparel businesses over screen printing?

The main advantages of DTF transfers for custom apparel businesses compared to screen printing include lower startup costs for small batch orders, faster turnaround times, and the ability to print detailed, colorful designs without compromising fabric softness. These factors make DTF an efficient and appealing choice for businesses aiming for quality and growth.

Why are DTF transfers becoming more popular in the custom printing market?

DTF transfers are gaining popularity in the custom printing market due to their several key benefits, including quick setup, cost-effectiveness on small orders, and the capability to print vivid images on diverse fabrics. Moreover, the ongoing advancements in DTF printing technology are democratizing access for both professionals and hobbyists alike.

What should I consider when choosing between DTF transfers and traditional printing methods?

When choosing between DTF transfers and traditional printing methods, consider factors such as the quantity of orders, fabric types, quality expectations, and budget constraints. DTF transfers typically provide benefits in efficiency, quality, and versatility, particularly for smaller runs and a variety of custom apparel applications.

| Aspect | DTF Transfers | Traditional Methods |

|---|---|---|

| Quality | High-fidelity images, maintains fabric softness | Thicker inks can make the fabric feel stiff |

| Efficiency | Faster setup and production times, ideal for small orders | Requires multiple setups and color separations, slower for small runs |

| Setup Costs | Lower costs for small batches, reduced waste | Higher upfront investment, often not cost-effective for small runs |

| Versatility | Suitable for a variety of fabrics and styles | Often limited to specific materials or styles |

| Market Adaptation | Rapidly growing with tailored solutions for users | Adapting but facing competition from new technologies |

Summary

DTF transfers are revolutionizing the custom printing landscape by offering unparalleled quality, efficiency, and versatility compared to traditional methods. As businesses increasingly seek agile solutions to meet consumer demands, DTF transfers stand out for their ability to deliver vibrant, durable prints on various fabrics without the logistical burdens associated with conventional printing techniques. The growing trend towards DTF technology highlights a significant shift in preferences within the apparel printing industry, positioning it as a preferred method for both small businesses and individual creators. In the competitive market of custom apparel, adopting DTF transfers not only enhances product quality but also streamlines the printing process, making it an essential consideration for anyone looking to thrive in this dynamic sector.