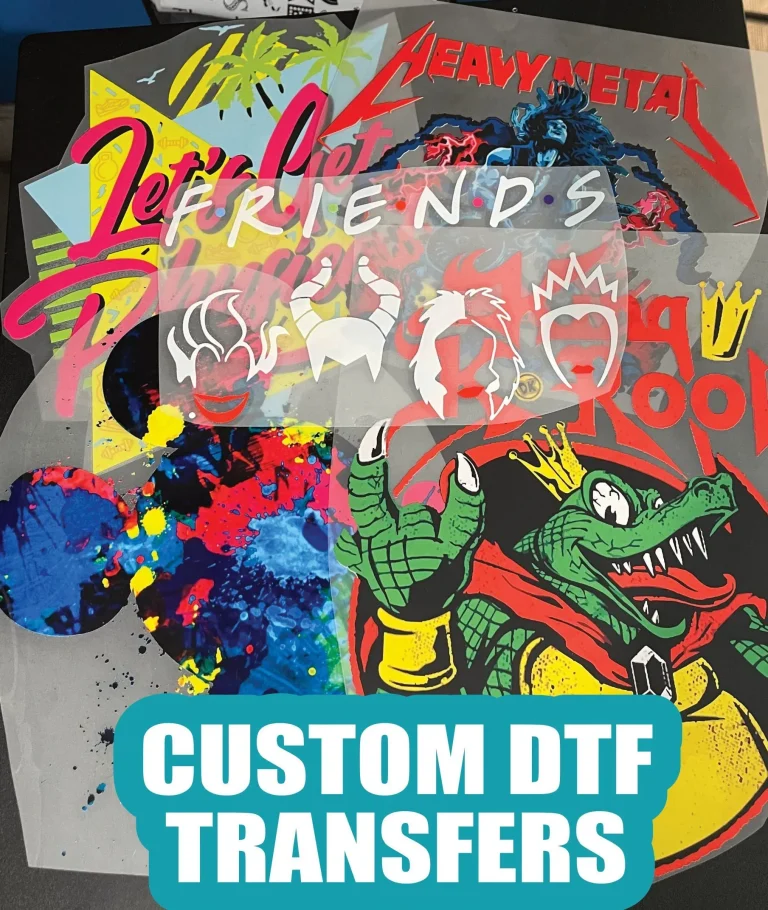

DTF Transfers, or Direct-to-Film transfers, represent a revolutionary trend in the realm of custom apparel and garment printing. This innovative technique allows for the transfer of intricate designs onto various fabrics, offering a high degree of versatility and quality that stand out against traditional screen printing alternatives. DTF printing not only accommodates a vast array of transfer sizes but also ensures vibrant, colorful outputs that cater to diverse consumer tastes. Whether you’re a DIY enthusiast or a business owner, leveraging DTF transfers can elevate your products with unique and personalized designs. As the market continues to embrace this technology, understanding its fundamentals and potential applications will be crucial to staying ahead in the competitive world of garment decoration.

Exploring Direct-to-Film applications reveals a new frontier in apparel customization. This technique utilizes specialized films that allow complex graphics to be easily applied to fabrics through heat transfer, offering a viable option for those seeking alternatives to traditional printing methods. Known for its adaptability, this process supports various sizes of transfers tailored to meet unique project requirements. As businesses and creatives alike dive into this realm, they uncover endless possibilities for imaginative design and efficient production. With the growing demand for personalized merchandise, understanding this modern approach to garment decoration can lead to significant advantages in the ever-evolving fashion landscape.

Understanding DTF Printing Technology

DTF printing technology, or Direct-to-Film printing, represents a transformative approach to customizing garments. This process involves transferring high-resolution images onto fabric using specialized films and heat, creating durable and vibrant designs. Unlike traditional methods such as screen printing, DTF provides a higher level of detail and color accuracy, making it an attractive option for businesses in the custom apparel sector.

Additionally, DTF technology adapts well to a range of fabrics, including cotton, polyester, and blends, making it perfect for diverse garment printing applications. As the demand for personalized clothing continues to surge, understanding DTF options becomes paramount for anyone looking to stand out in the crowded apparel market.

Choosing the Right DTF Transfer Size

When selecting a DTF transfer size, your first step should involve assessing your project’s requirements. DTF transfers are available in various dimensions, including standard sizes like A4 and A3, as well as fully customizable options to perfectly suit your design and fabric type. Smaller transfer sizes are often ideal for tight spaces, such as smaller garments or intricate designs, while larger sizes can accommodate bolder graphics and statements.

Be mindful that the right size impacts not only the aesthetics but also the durability of your print. A well-sized transfer will help to reduce the risk of cracking or peeling, which commonly occurs if oversized transfers are applied to smaller items. Always consider the ratio of the transfer to the garment for balanced, visually appealing results.

Transfer Sizes for Different Garment Types

Garment printing with DTF transfers demands an understanding of how sizes correlate with various apparel items. T-shirts commonly work well with A4 transfer sizes, enabling detailed printing without overwhelming the fabric’s design. Meanwhile, hoodies and bags may require larger A3 transfers or custom sizing to display more complex artwork attractively.

By strategically choosing transfer sizes based on the target garment, you ensure that the design complements rather than dominates the apparel. It’s essential to match the scale of your transfer with the apparel’s designated style while ensuring the artwork’s visibility and impact are maximized.

Market Trends in DTF Transfer Usage

The recent trends show a notable uptick in the utilization of DTF transfers among entrepreneurial ventures and niche markets. The customization potential offered by DTF technology has led small businesses to invest in larger transfer sizes, which cater excellently to the rising demand for intricate designs. This shift reflects a broader industry movement towards more personalized consumer experiences.

As screen printing alternatives increasingly adopt DTF due to its flexibility and quality, understanding market preferences will position businesses effectively. Keeping an eye on emerging trends not only aids in product development but also helps businesses stay relevant and competitive in a spiking demand environment for unique, custom apparel.

Best Practices for Implementing DTF Transfers

For optimal outcomes, implementing DTF transfers requires a strategic approach to size selection. A best practice is to maintain a diverse inventory of transfer sizes to cater to different customer preferences and project needs. Whether creating custom apparel for an event or fulfilling bulk orders, having both smaller and larger options at your disposal allows for greater flexibility and responsiveness to market demands.

Moreover, staying updated with the latest techniques in fabric preparation and heat application will enhance the overall quality of the final product. The intricacies of applying DTF transfers correctly can significantly affect the longevity and appeal of the design, ultimately leading to customer satisfaction and repeat business.

Enhancing Your Custom Apparel with DTF Transfers

DTF transfers empower designers to elevate their custom apparel offerings by infusing creativity directly into their garments. By choosing the right transfer sizes, businesses can create pieces that truly reflect the customer’s vision, whether through detailed graphics or vibrant color schemes. DTF technology allows for the coexistence of complex designs and fabric integrity.

Integrating well into the lifestyle of your target market, DTF enhancements should focus on quality and precision, ensuring each custom piece stands out in a competitive landscape. By focusing on tailored designs and appropriate sizing, businesses encounter fewer misprints and higher customer satisfaction rates.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing intricate designs on a special film that, when heated, adheres to various textiles. This method is popular in the custom apparel sector for its ability to produce vibrant, detailed designs, making it an excellent choice for garment printing.

What sizes are commonly available for DTF Transfers?

Common DTF transfer sizes include A4, A3, and fully customized options. The size you choose should depend on your project’s requirements, such as the garment type and the complexity of the design, ensuring it fits perfectly on your custom apparel.

How do I choose the right size for my DTF Transfer project?

Choosing the right size for your DTF transfer involves considering the garment dimensions and the design intricacies. For small items like t-shirts, A4 sizes may work best, while larger items, such as hoodies, might require A3 or custom-sized transfers for optimal visibility and appeal.

Are DTF Transfers a good alternative to screen printing?

Yes, DTF transfers are an excellent screen printing alternative as they offer greater versatility for complex and colorful designs. DTF printing technology allows for detailed imagery that adheres well to various fabrics, making it a preferred choice for many custom apparel creators.

Can I customize DTF Transfer sizes for my projects?

Absolutely! One of the key advantages of DTF technology is its customization capability. You can tailor DTF transfer sizes to meet the specific dimensions required by your design, accommodating various fabric styles and ensuring a perfect fit for your garment printing needs.

What are the best practices for using DTF Transfers in commercial applications?

For commercial applications, it is advisable to invest in both small and large DTF transfer sizes to meet diverse client demands. This flexibility can enhance your service offerings and improve competitiveness in the custom apparel market, as different projects may require different transfer sizes.

| Key Points | Details |

|---|---|

| Overview of DTF Transfers | DTF technology allows intricate designs on various fabrics using heat, providing high-quality and colorful results. |

| Understanding DTF Transfers | DTF transfers come in different sizes (A4, A3, custom) that meet specific project needs. |

| Key Size Considerations | Transfer sizes affect aesthetics and functionality; consider garment type and design complexity. |

| Market Trends | Increasing popularity among businesses and startups; larger sizes offer intricate designs. |

| Customization Capabilities | DTF technology allows tailor-made transfers to suit diverse fabric styles and sizes. |

| Best Practices for Personal Projects | Opt for smaller to medium sizes for custom apparel to maintain budget efficiency. |

| Best Practices for Commercial Use | Invest in both small and large transfers to cater to a wide range of client demands. |

| Making the Right Choice | Understanding size options influences the final product’s appearance and feel. |

Summary

DTF Transfers have become an essential aspect of modern garment printing, revolutionizing the way custom designs are applied to fabrics. As the printing industry evolves, grasping the significance of size when selecting DTF transfers is vital to achieving stunning results. By understanding the various transfer size options and their impacts on project requirements, you can create visually striking garments that meet both aesthetic and functional needs. Whether you are a hobbyist or a business, mastering the art of DTF Transfers will empower you to deliver exceptional customized apparel.