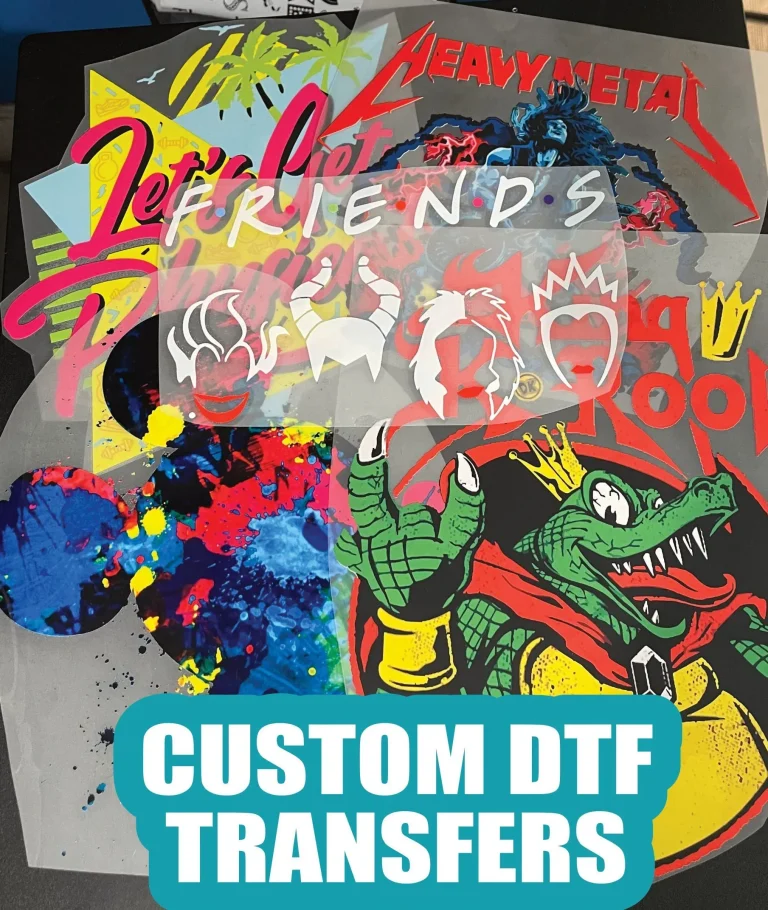

DTF transfers, or Direct-to-Film transfers, have revolutionized the world of printing by providing exceptional quality and versatility across various materials. This innovative DTF printing technology employs a specialized transfer film that allows for detailed designs to be printed and transferred seamlessly onto fabrics, plastics, and more. Understanding the crucial role of size in DTF transfers not only impacts the final product’s quality but also enhances the clarity of print file resolution for large prints. As you delve into DTF transfers, you will discover how heat press settings and the dimensions of both your design and transfer film dictate the adherence and overall success of the transfer process. By mastering these elements, you can ensure vibrant designs that captivate and inspire.

Also known as Direct-to-Film transfer techniques, DTF printing stands out due to its ability to produce high-quality images on a variety of substrates. This process begins with printing designs onto a unique film, which can then be smoothly transferred to a range of materials, including textiles, wood, and plastics. The importance of size cannot be understated, as it influences print quality and the effectiveness of the transfer. By selecting the right dimensions in print file resolution and utilizing proper heat press settings, users can achieve optimal results that enhance the durability and vibrancy of their designs. Embracing DTF transfer technology allows for creative possibilities and ensures that every printed piece shines.

Understanding DTF Transfers and Their Impact on Size

Direct-to-Film (DTF) transfers are revolutionizing the printing world by offering an efficient and reliable method for fabric printing. However, one cannot overlook the significance of size when it comes to achieving optimal results. DTF printing involves applying specially formulated inks onto a transfer film, which is then heat-pressed onto a substrate. The dimensions of both the print file and the transfer film must align correctly to ensure that every detail of the design is accurately captured. A miscalculated size can lead to unsatisfactory outcomes, underscoring the critical need for precision in both the digital and physical components of the process.

Moreover, the size of your design file directly impacts the print file resolution. Higher resolution files produce better clarity and sharpness, which are essential, especially for larger prints. In contrast, lower resolution files can suffer from pixelation and blurriness, detracting from the quality of the transfer. Therefore, understanding how size correlates with both the digital aspect and the physical film is key for anyone looking to employ DTF technology effectively.

Frequently Asked Questions

What is DTF transfers and how does size affect print quality?

DTF transfers, or Direct-to-Film transfers, are a printing method where designs are printed on a specialized film before being transferred to various materials. The size of both the digital print file and the transfer film is crucial; larger sizes require higher resolutions (300 DPI or more) to maintain clarity. If the file size is too small, the print may become pixelated, whereas using a transfer film slightly larger than the design ensures complete coverage and prevents missed spots.

How does print file resolution impact DTF transfers?

Print file resolution directly impacts the quality of DTF transfers. To achieve sharp and clear images, especially for larger designs, it’s recommended to use a resolution of 300 DPI or higher. This ensures that the details are crisp, preventing any blurriness or pixelation during the transfer process.

What is the ideal transfer film size for DTF printing?

The ideal transfer film size for DTF printing should match the design dimensions but be slightly larger. This extra margin is crucial as it guarantees complete coverage of the intended transfer area, preventing any gaps or missed areas that could compromise the final print quality.

What heat press settings are recommended for DTF transfers?

Heat press settings for DTF transfers can vary based on the transfer film size and the substrate used. It’s essential to familiarize yourself with optimal pressure and temperature settings according to the specifications of the film and material type. Improper settings can lead to issues like peeling or incomplete transfers, affecting the print outcome.

What recent developments in DTF printing should I know about?

Recent developments in DTF printing include enhanced ink technologies that improve adhesion and flexibility across various substrates, as well as the rise of eco-friendly inks that deliver quality prints without the environmental impact. Both advancements emphasize the need to consider size and print specifications for outstanding results.

Why is understanding sizing crucial for DTF transfers?

Understanding sizing is critical for DTF transfers as it influences both the digital design and transfer film, which affects print quality. Proper sizing ensures that prints remain detailed and clear while allowing for effective transfer application, ultimately leading to successful and visually appealing results.

| Key Point | Description |

|---|---|

| File Resolution and Digital Size | Higher resolutions (300 DPI) are necessary for larger prints to prevent pixelation. |

| Transfer Film Size | Select a film slightly larger than the design to ensure complete coverage. |

| Heat Pressing Considerations | Correct heat and pressure settings are crucial for successful transfers, varying by size. |

| Enhanced Ink Technology | New inks improve adhesion and flexibility, suitable for diverse substrates. |

| Eco-friendly Options | Sustainable inks are emerging, offering high quality without size limitations. |

Summary

DTF transfers are pivotal in achieving high-quality prints that resonate with clarity and vibrancy. Understanding the significance of size—both in your digital designs and the transfer films—can dramatically enhance the final output of your projects. When it comes to DTF transfers, getting the sizing right not only ensures optimal print quality but also minimizes errors during the transfer process. By prioritizing these size considerations and staying updated with the latest advancements, professionals in the DTF printing industry can consistently produce stunning results that highlight the beauty of their designs.