DTF transfers, or Direct-to-Film transfers, are quickly transforming the landscape of custom T-shirt printing and apparel customization. This innovative transfer printing technique allows artists and entrepreneurs to produce vibrant, intricate designs that adhere seamlessly to various fabrics. With the rise in popularity of DTF printing, more individuals are discovering how this method offers both superior quality and exceptional durability for their personalized garments. Whether you’re a seasoned professional or a hobbyist, mastering DTF transfers can unlock countless opportunities to create custom apparel that truly stands out. In this post, we’ll delve into the world of DTF transfers and provide you with essential insights for achieving stunning results.

When discussing custom apparel techniques, you might come across terms like film transfers or direct garment printing. These methods, including the increasingly popular DTF process, enable enthusiasts to showcase their artistic flair and create bespoke clothing items. Whether you refer to it as transfer printing or apparel customization, the underlying principle remains the same: harnessing advanced techniques to bring unique designs to life. As the demand for personalized garments rises, staying informed about innovations in heat press techniques and printing methods is crucial for any creative looking to thrive in this dynamic industry.

Understanding the Benefits of DTF Transfers

DTF transfers offer a multitude of benefits for both hobbyists and professional custom T-shirt designers. One of the primary advantages is the ability to create vibrant, high-quality prints that boast excellent color vibrancy. This feature makes DTF particularly appealing for intricate designs and detailed graphics, which are essential when you aim to stand out in the crowded apparel market. In addition, DTF transfers are compatible with a variety of fabrics, including cotton and polyester, making it a versatile option for different apparel customization projects.

Beyond the aesthetic quality, DTF printing is also cost-effective for small businesses and individuals looking to scale their custom apparel operations. The process eliminates the need for complex screen printing setups, allowing for easier management and lower overhead costs. As more consumers seek personalized clothing options, DTF transfers provide a pathway to meeting this demand efficiently while maintaining high standards of print quality.

The DTF Transfer Process: A Step-by-Step Approach

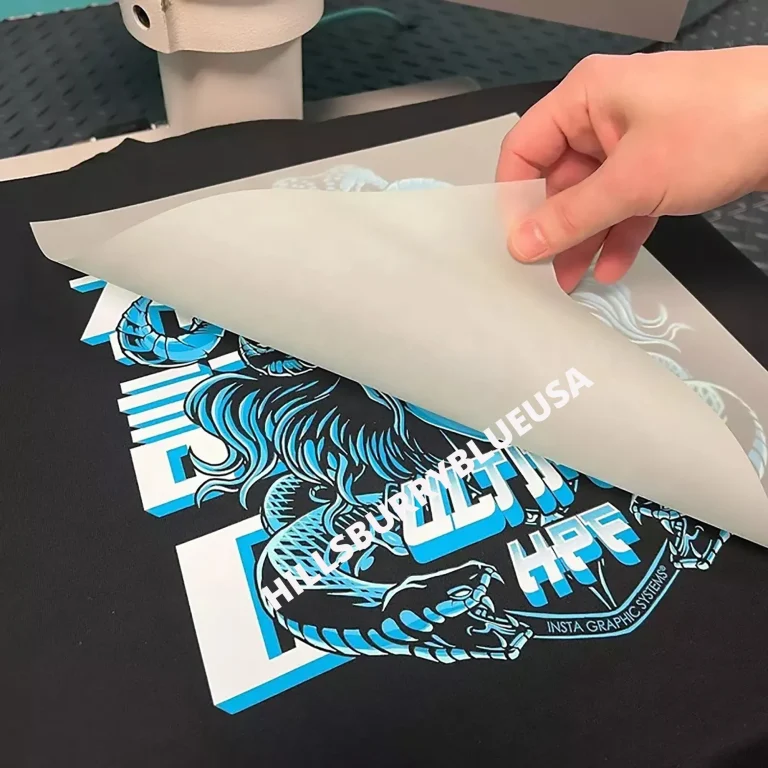

Mastering DTF transfers involves understanding the detailed steps of the process. First, begin by preparing a high-resolution design. The use of graphic design software enables you to create or modify artwork efficiently, ensuring that it prints clearly on the PET film. Once your design is ready, setting up the DTF printer is paramount. Ensure that all components are properly configured to avoid common pitfalls that novice users might encounter.

Next comes the actual printing on PET film, where adequate drying time is crucial before applying the hot melt adhesive powder. These steps, from printing to heat pressing, require precision and care. The final results depend on the settings you choose for application, including temperature and pressure, which must be adjusted depending on the fabric type to achieve optimal adhesion. Following these steps diligently will lead to stunning, professional-quality apparel.

Latest Innovations in DTF Printing Equipment

The world of DTF printing technology is evolving rapidly, with manufacturers continuously innovating to cater to both amateur and professional markets. Recent advancements have resulted in user-friendly DTF printers, which are equipped with faster printing speeds and enhanced ink formulations. This technological shift not only minimizes the barrier to entry for small businesses but also maximizes efficiency in production, allowing for quicker turnaround times on custom orders.

These new machines often come with intuitive interfaces, making them accessible for novices while still offering the precision that experienced users expect. Investment in the latest DTF printing equipment will not only streamline your workflow but also improve the overall quality of your print jobs, ensuring that your custom T-shirts are suitable for a competitive market.

Troubleshooting Common Issues with DTF Transfers

As with any printing method, DTF transfer printing can present some challenges, particularly for those new to the process. Common issues such as design not adhering to the fabric can often be traced back to incorrect heat settings. Ensuring that your heat press maintains the appropriate temperature and pressure is fundamental to achieving a strong bond between the transfer and the fabric.

Additionally, ink smearing can occur if the ink has not sufficiently dried before applying the adhesive powder. To mitigate this risk, allowing your printed designs ample time to cure will improve overall print quality. When facing difficulties, having access to community resources or forums can provide valuable troubleshooting advice that may refine your skills in DTF transfers.

Eco-Friendly Practices in DTF Printing

Sustainability is becoming a vital concern for businesses in the custom apparel industry, and DTF printing is no exception. Many manufacturers are now focusing on eco-friendly inks and materials to reduce their environmental impact while still delivering high-quality products. By adopting sustainable practices, businesses can appeal to environmentally conscious consumers and set themselves apart in a crowded marketplace.

Incorporating sustainable methods not only benefits the planet but can also enhance a brand’s reputation among modern consumers who prioritize environmental responsibility. As the industry evolves, embracing eco-friendly practices in your DTF transfer operations will not only meet consumer demands but can also position your business as a leader in the shift towards sustainable fashion.

Creating a Community Around DTF Printing

Engaging with the DTF printing community can significantly enhance your skills and knowledge. Online forums, social media groups, and local meetups provide platforms for enthusiasts to share experiences, troubleshoot common problems, and exchange tips for improving their DTF transfer techniques. Being part of a community fosters a support network that is invaluable, especially for newcomers to the customization world.

Participating in discussion groups can lead to discovering new techniques, such as variations in heat press techniques, which can elevate your DTF printing projects. Networking with fellow enthusiasts not only encourages growth and learning but may also open doors to collaborative projects and partnerships, enriching your journey in the vibrant world of custom apparel.

Frequently Asked Questions

What is DTF transfer printing and how does it work?

DTF transfer printing, or Direct-to-Film transfer printing, is a modern technique for customizing apparel, such as T-shirts. It involves printing a design onto a special PET film, applying adhesive powder to the wet ink, and then using a heat press to transfer the design onto fabric. This method allows for vibrant colors and intricate designs.

What materials can be used with DTF transfers?

DTF transfers are versatile and can be applied to a variety of materials, including cotton, polyester, and blends. This compatibility makes DTF printing a popular choice for custom T-shirts and diverse apparel types.

What are the benefits of using DTF printing for custom T-shirts?

Using DTF printing for custom T-shirts offers numerous benefits, including excellent color vibrancy, detailed graphic reproduction, and the ability to create designs on various fabric types. It also allows for quick production times, making it ideal for personalized apparel.

How can I troubleshoot common issues with DTF transfers?

Common issues with DTF transfers, such as designs not adhering or ink smearing, can often be resolved by ensuring proper heat press settings, allowing the ink to dry completely, and using high-quality materials. Make sure your printer is set up according to manufacturer guidelines for optimal results.

What equipment is needed for DTF transfer printing?

To get started with DTF transfer printing, you’ll need a compatible inkjet printer, special PET film, hot melt adhesive powder, and a heat press. Investing in quality equipment ensures better results and more successful custom apparel designs.

Are there educational resources available for mastering DTF transfers?

Yes, there are numerous educational resources available for mastering DTF transfers. Online platforms like YouTube, blogs, and communities dedicated to DTF printing offer tutorials, tips, and troubleshooting advice to help you enhance your skills and create stunning custom apparel.

| Key Points | Details |

|---|---|

| What is DTF Transfer Printing? | A method for customizing clothing using inkjet printing on PET film, which is then heat-pressed onto fabric for durable designs. |

| Process Steps | 1. Print design on film. 2. Apply adhesive powder on wet ink. 3. Heat press the film onto the fabric. |

| Advantages | – Excellent color vibrancy – Detail-oriented, suitable for intricate designs – Compatible with various fabrics such as cotton and polyester. |

| Recent Developments | – User-friendly DTF printers now available. – Growth in demand for personalized apparel. – Eco-friendly innovations in materials and inks. – Communities providing support and resources. |

| Troubleshooting Tips | – Adjust heat press temperature if designs do not adhere. – Ensure ink is dry to prevent smearing. |

Summary

DTF transfers have revolutionized the world of custom apparel, making it easier than ever to create vibrant, detailed designs. This method allows you to combine personal creativity with practical skills, enabling you to produce high-quality garments that meet diverse consumer demands. By mastering DTF transfer printing, you not only enhance your creative expression but also tap into a prosperous market for customized clothing. Whether you’re using innovative technology or leveraging community resources, the journey to mastering DTF transfers is rewarding and filled with opportunities for growth.