When it comes to enhancing your DTF printing outcomes, optimizing DTF transfers by size becomes an essential area of focus. This technique not only influences the visual appeal of your prints but also their overall efficacy on different fabric types. As the DTF printing technique gains traction among artists and businesses alike, understanding transfer optimization is pivotal for success in this evolving landscape. From adjusting heat press settings to implementing effective design scaling, every detail plays a significant role in achieving the desired finish. By mastering these practices, you will elevate your printing experience and ensure your designs remain vibrant and striking.

In the realm of Direct to Film printing, maximizing the quality of your transfers hinges on meticulous size adjustments and strategic print management. This transformative method allows users to apply intricate designs onto fabrics, but the success of each transfer greatly depends on careful considerations around dimensions and material compatibility. Utilizing alternative phrases like “transfer enhancement” and “design dimension management” highlights the multifaceted nature of print production. Moreover, employing proper heat application and optimizing design scaling are integral to generating standout results. As you navigate this dynamic printing field, sophistication in your approach can set you apart from conventional practices.

Understanding DTF Printing Techniques

Direct to Film (DTF) printing is rapidly becoming a favorite among textile printers due to its ability to produce detailed and colorful designs efficiently. This technique involves printing ink onto a special film, which is then transferred onto the fabric using heat and pressure. Understanding the intricacies of DTF printing techniques is crucial for achieving optimal results. The process itself is quite straightforward, but several variables, including the type of fabric and the size of the transfer, can significantly impact the final quality of the print.

In terms of size, a well-calibrated design is essential. If a design is printed too large, it can distort during the heat transfer, leading to blurriness and a loss of detail. On the other hand, a too-small design can become nearly invisible, losing its impact on the fabric. Therefore, mastering DTF printing techniques requires a balance between vibrant designs and appropriate scaling to ensure the final product is visually striking.

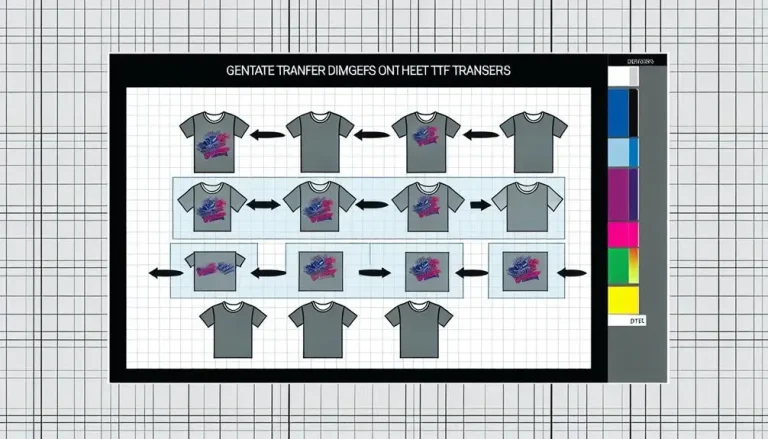

Optimizing DTF Transfers by Size

Optimizing DTF transfers by size ensures that the final printed product reflects the intended design details and clarity on the fabric. To start, it is essential to consider the dimensions of your transfer in relation to the garment size. A transfer that is too small may not only lack visibility but can also impact how the colors appear on different fabric types. Ensuring the right size helps maintain the integrity of the design during the transfer process, showcasing vibrant colors and intricate details effectively.

Moreover, adjusting the size based on fabric type cannot be overlooked. For instance, larger transfers are often preferable on textured fabrics to ensure that the design captures attention and is noticeable against the material. By optimizing transfer size, you’ll not only enhance your design’s visibility but also improve customer satisfaction with the final product, making your prints truly stand out.

Key Heat Press Settings

Heat press settings can make or break the quality of your DTF prints, and they demand careful consideration based on the size of your transfer. For larger designs, applying even and adequate pressure is vital, as uneven heat distribution can lead to defective areas where the transfer may not adhere properly. This aspect of heat press application becomes even more critical when printing on thicker fabrics which may require higher temperatures and longer pressing times to penetrate adequately.

In addition, it’s important to monitor the temperature applied to the transfer size. Excessive heat can damage the fabric or cause the transfer to bubble, creating an unattractive and unprofessional finish. Therefore, optimizing heat press settings relative to transfer size is crucial for achieving durable and visually impressive prints that uphold quality standards.

Tips for Effective Design Scaling

When scaling designs for DTF printing, maintaining the aspect ratio is fundamental. Failure to do so can result in pixelation or blurriness of the final print. Working within design software allows you to set specific dimensions that match your fabric type, which can help maintain the quality of the design. Utilizing vector graphics can greatly enhance clarity as these graphics can be scaled without losing resolution.

Additionally, always preview your scaled designs on the actual garment size digitally before finalizing for print. This step provides a great opportunity to realize how the design will interact with the fabric type, allowing adjustments in size or layout to improve overall output. By approaching design scaling with precision, you can ensure that your DTF transfers look stunning on any fabric.

Conducting Test Prints for Optimization

Conducting test prints is a critical component in the DTF printing process, especially when experimenting with different sizes. By testing various dimensions on sample fabric, printers can evaluate how each size translates into color vibrancy and detail retention. This practice serves not only to fine-tune the ideal dimensions for the final product but also to understand how different fabrics react to various transfer sizes.

Documenting results from test prints allows for systematic adjustments and optimizations, ensuring every subsequent print run is of the highest quality. This technique also builds valuable insights for scaling designs more effectively in future projects, helping to deliver flawless prints that fully satisfy design objectives.

The Impact of Material Selection on DTF Transfers

The selection of material for DTF printing significantly impacts the outcome of your transfers. For instance, natural fibers, such as cotton, tend to absorb ink more thoroughly, resulting in bright and vivid colors. In contrast, synthetic materials like polyester may exhibit more muted tones, which can influence how design sizes are optimized. Understanding these interactions allows printers to tailor their transfer sizes to meet the requirements of each fabric type specifically.

Furthermore, different materials may have varied characteristics that affect how designs appear when printed. Heavier fabrics may require larger designs to ensure that they are visible and don’t get lost in the texture, while lighter materials can benefit from more intricate designs. By taking material into account when determining transfer size, printers can enhance the aesthetic appeal of their prints.

Frequently Asked Questions

How can I optimize DTF transfers by size for better quality?

To optimize DTF transfers by size, it’s important to scale your designs appropriately while maintaining the aspect ratio. Avoid oversized designs that might pixelate and undersized transfers that can lose detail. Conducting test prints at various sizes will help find the best resolution for your specific fabric.

What are key DTF printing tips for design scaling?

Key DTF printing tips for design scaling include ensuring you maintain the correct aspect ratio during scaling, using design software to match your target fabric size, and producing test prints to gauge how well designs translate onto different materials.

What heat press settings should I use based on transfer size during DTF printing?

When applying DTF transfers, larger transfers often require higher heat settings and more pressure to ensure even application. Experimenting with different heat and pressure settings is crucial based on the size of your transfer to achieve proper ink penetration and durability.

How does fabric type affect optimizing DTF transfers by size?

Fabric type significantly influences how DTF transfers appear; for instance, cotton can absorb more ink, resulting in vibrant colors, while polyester may show subdued tones. Adjusting transfer sizes based on fabric characteristics ensures that the designs remain visible and impactful.

Why is testing different print sizes important for DTF printing?

Testing various print sizes is essential in DTF printing as it enables you to determine the optimal scale for clarity and vibrancy of your designs. By documenting the outcomes, you can refine your processes and achieve higher quality prints suitable for diverse fabric types.

What are the latest trends in DTF printing that affect transfer size optimization?

The latest trends in DTF printing include advancements in printer technology that allow for larger film sizes. Adapting to these trends enables greater customization and flexibility in designs, thereby enhancing the overall quality of DTF transfers by size.

| Strategy | Description |

|---|---|

| Design Scaling | Maintain aspect ratio to avoid pixelation. Reformats graphics for specific transfer sizes. |

| Conduct Test Prints | Test various sizes on different fabrics to determine optimal resolution and scaling. |

| Material Considerations | Fabric type influences print quality. Adjust transfer size based on material characteristics. |

| Heat and Pressure Settings | Larger transfers require careful heat press settings for durability and ink penetration. |

| Current Trends and Technologies | Stay updated on DTF advancements for improved customization and efficiency. |

| Educational Resources | Utilize online tutorials for tips on optimizing transfers and troubleshooting. |

Summary

Optimizing DTF transfers by size is crucial for achieving exceptional print quality. By carefully scaling your designs, conducting test prints, and considering the fabric type, you can improve the visual appeal and durability of your prints. Additionally, adjusting heat and pressure settings according to transfer size plays a significant role in ensuring the ink adheres properly. Staying informed about current trends and utilizing educational resources enhances your understanding and effectiveness in DTF printing. By focusing on these strategies, you can significantly elevate your output and stand out in the competitive printing landscape.