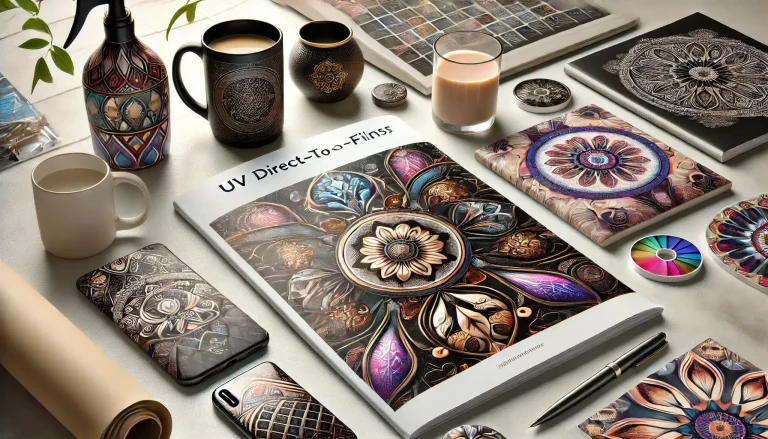

UV DTF Transfer Techniques are redefining the landscape of garment decoration by merging cutting-edge technology with the need for high-quality prints. This innovative approach utilizes UV printing combined with Direct-to-Film (DTF) methods, enabling artists and businesses to create stunning, durable designs on a variety of substrates. The versatility of UV DTF applications extends from textiles to hard surfaces, allowing for an expansive range of custom apparel options that cater to diverse consumer needs. With increasing emphasis on sustainable printing practices, UV DTF techniques stand out as an eco-friendly choice, utilizing formulations that minimize harmful environmental impacts. Join us as we explore the significant advantages and practical implementations of UV DTF transfer techniques in today’s competitive printing market.

In the realm of modern printing technologies, the rise of UV Direct-to-Film applications is making a significant impact on the customization of apparel and promotional items. This technique offers a fresh perspective on garment decoration by integrating ultraviolet curing systems with film transfer methods, paving the way for vibrant and resilient prints on various materials. The adaptability of UV DTF technology makes it a top choice for businesses looking to provide unique and personalized products while meeting the growing demand for sustainable printing solutions. Additionally, the evolving landscape of textile and surface printing is becoming increasingly inclusive, thanks to the wide range of substrates that can be printed upon using this method. As we delve deeper into the world of UV DTF, we’ll uncover its many benefits and the opportunities it presents for the future of printing.

Understanding UV Printing Technology

UV printing technology has emerged as a revolutionary process in the realm of garment decoration. It leverages ultraviolet light to cure inks almost instantly upon application, resulting in sharp, vibrant designs that stand out. This technique is distinct from traditional printing methods as it allows for printing on a wider range of substrates, including unconventional materials such as plastics and metals. With its ability to create high-quality images that are resistant to wear, UV printing opens new doors for custom apparel and promotional items, providing a durable finish that end users will appreciate.

The mechanics of UV printing involve using specialized inks that react to ultraviolet light. Once exposed, these inks solidify, making the process incredibly fast and efficient. In addition to its quick curing times, UV printing minimizes smudging and ghosting, issues often faced with standard printing technologies. For businesses, this translates into lower production costs and enhanced profit margins, as quicker turnaround times can accommodate a higher volume of orders.

Exploring the Versatility of UV DTF Transfer Techniques

One of the hallmarks of UV DTF transfer techniques lies in their unmatched versatility. This innovative method allows for printing on a multitude of materials, from soft textiles to rigid surfaces, which is a significant advancement over conventional DTF approaches. As brands and designers strive for distinction in crowded markets, the ability to produce high-quality custom apparel on diverse substrates enables businesses to cater to specific client demands and trends. Products can range from personalized gifts to corporate branding items, thus broadening the revenue potential for companies.

Moreover, the adaptability of UV DTF technology empowers businesses to experiment creatively with their offerings. Entrepreneurs can easily introduce new product ideas or seasonal promotions, knowing that the printing process can accommodate varying materials and sizes. This flexibility not only enhances customer engagement but also positions businesses favorably in the competitive landscape of garment decoration.

The Environmental Benefits of Sustainable Printing

As sustainability becomes a growing concern for consumers, the importance of eco-friendly printing solutions cannot be overstated. UV DTF transfer techniques utilize inks that are typically free from harsh solvents, thereby reducing harmful emissions during the printing process. This environmentally conscious approach aligns with the values of today’s consumers, who are increasingly supporting brands that embrace sustainable practices.

Furthermore, the longevity of the prints produced through UV DTF techniques contributes to sustainability efforts, as longer-lasting products reduce the frequency of replacements and reprints. This not only saves resources but also minimizes waste, creating a win-win for businesses and the environment. By adopting UV DTF methods, companies can enhance their brand image and attract a customer base that is increasingly devoted to sustainability.

Advancements in Printing Technology for Faster Production

The rapid evolution of printing technology has made it possible for businesses to optimize their production processes significantly. With the introduction of UV DTF transfer techniques, companies can expect faster production speeds without compromising on quality. This improvement is particularly advantageous for businesses looking to manage large orders efficiently while still meeting client expectations for high-quality output.

The ability to streamline production workflows not only reduces wait times for clients but also allows businesses to take on more orders. As a result, companies equipped with advanced UV DTF printing capabilities can enjoy a competitive edge in the market. Enhanced training sessions dedicated to mastering these technologies ensure that workforce skill levels rise, leading to an overall increase in operational efficiency and production accuracy.

Training and Skill Development in UV DTF Printing

Education and skill development are crucial for maximizing the potential of UV DTF transfer techniques. As this technology advances, training programs have adapted to educate technicians and designers on best practices in file optimization, machine settings, and transfer procedures. Understanding how to prepare design files effectively ensures that artwork translates beautifully from digital format to printed product, crucial for maintaining reputable quality standards.

Moreover, continuous learning opportunities allow individuals in the printing industry to stay abreast of the latest technologies and trends. Workshops and online courses focused on UV DTF printing can cover everything from the nuances of color calibration to troubleshooting common production challenges. Investing in employee development not only boosts morale and retention but also enhances the overall output quality, creating a robust foundation for business growth.

Future Trends in Custom Apparel and UV DTF Techniques

As the demand for customization continues to rise, the future of the custom apparel market looks promising, especially for those utilizing UV DTF techniques. Shoppers are increasingly seeking unique, personalized garments that reflect their individual styles, and businesses that harness UV printing technology will be well positioned to meet this demand. This shift toward personalized products signifies a significant opportunity for growth, as consumers seek to express themselves through their clothing choices.

In conjunction with this trend, technological advancements will likely further enhance the capabilities of UV DTF printing. Innovations such as improved ink formulations, faster curing processes, and better substrate compatibility will continue to push the boundaries of what is possible in garment decoration. Brands that embrace these developments can differentiate themselves in a crowded market and cater to the desires of the contemporary consumer more effectively.

Frequently Asked Questions

What is UV DTF printing and how does it differ from traditional printing methods?

UV DTF printing, or UV Direct-to-Film transfer, combines UV printing technology with a film transfer process. It differs from traditional methods by using UV curable inks that create strong, vibrant images on transfer films, which can then be applied to a wide variety of substrates, including textiles and hard surfaces. This method ensures enhanced durability and vivid colors, setting it apart from older printing techniques.

What are the benefits of using UV DTF transfer techniques for garment decoration?

The benefits of using UV DTF transfer techniques for garment decoration include exceptional durability, resistance to fading and scratching, and the ability to print on diverse materials. Additionally, this sustainable printing method reduces environmental impact, thus appealing to eco-conscious consumers in the custom apparel market.

How does UV printing enhance the quality of UV DTF transfers?

UV printing enhances the quality of UV DTF transfers by utilizing specialized inks that cure instantly under ultraviolet light, resulting in sharp images with vibrant colors. This printing technology offers better adhesion and durability compared to traditional inks, making it ideal for high-quality custom apparel that withstands wear and tear.

Can UV DTF transfer techniques be applied to various materials and substrates?

Yes, UV DTF transfer techniques can be applied to a wide range of materials and substrates, including textiles, plastics, metals, and ceramics. This versatility makes UV DTF printing a popular choice for businesses looking to diversify their custom apparel offerings and cater to different markets.

Is UV DTF printing a sustainable option for businesses in the garment decoration industry?

Yes, UV DTF printing is considered a sustainable option as it typically uses eco-friendly inks that are free from harmful solvents. This results in a lower environmental impact compared to traditional screen printing methods, making it an attractive choice for brands aiming to enhance their sustainability credentials in custom apparel production.

What training resources are available for mastering UV DTF transfer techniques?

Various training resources are available for mastering UV DTF transfer techniques, including workshops focused on file optimization, machine configuration, and transfer procedures. Engaging in these training sessions enables technicians and designers to improve their skills and enhance production quality in garment decoration.

| Key Points | Details |

|---|---|

| Introduction | Overview of UV DTF transfer techniques combining UV printing with DTF for vibrant, durable prints. |

| What is UV DTF Printing? | Integration of UV inks with a transfer technique to print on films before transferring to surfaces. |

| Advantages of UV DTF Transfer | 1. Enhanced Durability 2. Wide Range of Printable Substrates 3. Sustainability 4. Flexible Production Processes 5. Market Growth Opportunities |

| Training Resources | Training available for file optimization, machine configuration, and transfer procedures. |

| Conclusion | Emphasizes the necessity of UV DTF techniques for businesses in the evolving printing market. |

Summary

UV DTF transfer techniques are essential for modern businesses looking to innovate in garment decoration. This printing method combines the strengths of UV printing and transfer technology to create stunning, long-lasting prints across various materials. With its numerous advantages including durability, versatility, and sustainability, UV DTF remains at the forefront of printing solutions. As companies invest in training and adopt these techniques, they are well-positioned to capture the growing demand for customized products. The future of garment decoration is bright with UV DTF techniques leading the way.