UV DTF transfer technology is revolutionizing the art of printing by harnessing cutting-edge methods to produce vibrant designs on a variety of surfaces. Utilizing the Direct to Film printing process, this innovative technique allows for direct application of UV inks onto films, which can be transferred onto textiles, plastics, and even metals. As the demand for customized printing solutions grows, understanding the intricacies of UV DTF applications becomes essential for professionals in the field. This guide will delve into valuable tips for UV DTF, empowering you with knowledge to achieve successful UV DTF projects that stand out in quality and durability. Embracing this technology not only enhances your capabilities but also sets you on a path toward delivering stunning prints that meet client expectations.

When discussing UV DTF transfer methods, one might also refer to it as Direct to Film printing, a term that underscores the process of printing designs directly onto films for subsequent application. This technology encompasses a range of applications, enabling artists and manufacturers to create exceptionally vivid graphics that adhere to various surfaces. Understanding the ins and outs of UV DTF applications is crucial for anyone looking to excel in this competitive printing landscape. This comprehensive overview will equip followers of UV DTF techniques with insightful tips for achieving optimal results, ensuring that your print projects not only meet but exceed expectations. In a market that continually evolves, staying informed about successful UV DTF methods can significantly enhance your creative and commercial potential.

Exploring the Versatility of UV DTF Transfer Technology

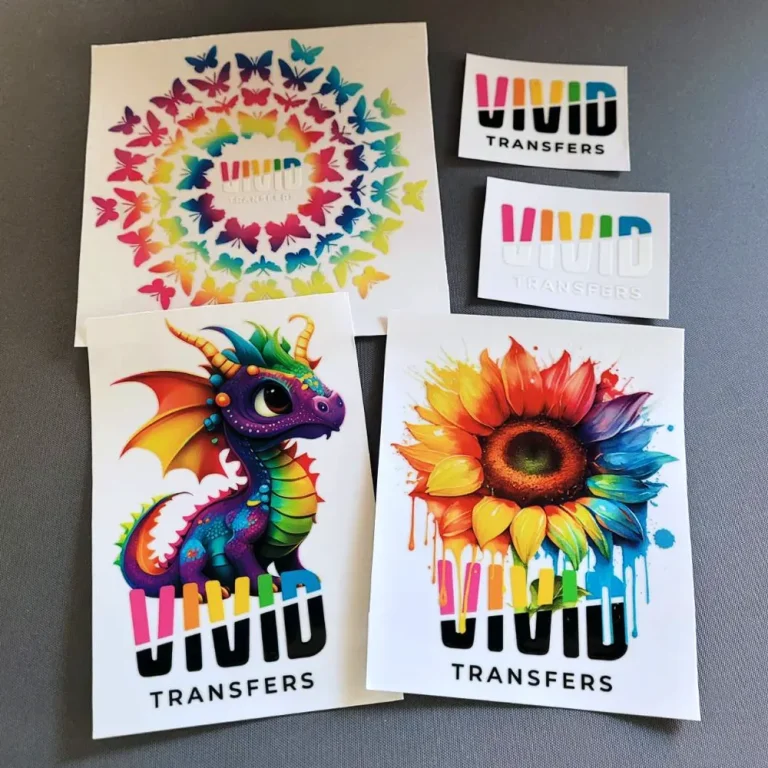

UV DTF transfer technology is quickly becoming a game-changer in the printing industry, thanks to its remarkable versatility. This method allows designers to apply vibrant, high-resolution images to various substrates, including textiles, plastics, and metals. As this technology evolves, it opens up new avenues for creative expression across different industries. From promotional items to personalized gifts, the applications are endless, making it an ideal choice for entrepreneurs and businesses looking to expand their product offerings.

Moreover, the adaptability of UV DTF transfers enables businesses to cater to a growing demand for customized products. Whether you are producing team apparel, unique packaging, or bespoke promotional materials, UV DTF technology delivers consistent quality and durability that fulfills modern consumer expectations. Its ability to print on both flat and uneven surfaces further enhances its appeal, allowing even the most intricate designs to be transferred flawlessly.

Essential Tips for High-Quality UV DTF Transfers

Achieving exceptional results with UV DTF transfers requires careful attention to detail and the application of best practices. One of the most crucial tips is to choose the right transfer film that is designed specifically for UV DTF processes. Quality films improve adhesion, color vibrancy, and overall print durability. Consider conducting research to identify the top-rated films in the market that augment the benefits of the UV DTF transfer method.

In addition to selecting the appropriate transfer film, optimizing print settings is equally important. Utilize the recommended profiles for UV inks to ensure accurate color representation. High-resolution settings should also be employed to maintain clarity and prevent issues like ink bleeding. These initial steps lay the foundation for producing outstanding prints that captivate clients and stand the test of time.

Mastering the Curing Process in UV DTF Printing

The curing process is a critical aspect of UV DTF printing that directly impacts print quality and longevity. Proper curing ensures that the inks adhere correctly to the substrate and achieve full hardness, which enhances the overall durability of the final product. Following the manufacturer’s guidelines for curing times and distances is crucial—any deviations may result in prints that don’t withstand everyday use.

Additionally, investing in high-quality curing equipment can make a significant difference. Advanced UV curing systems offer improved efficiency and better results, allowing you to produce more prints in a shorter time while maintaining high quality. Mastering this step is essential to ensure that your UV DTF transfers are not only beautiful but also resilient, aligning with customer expectations for durability.

Prepping Substrates for Successful UV DTF Applications

Substrate preparation plays a pivotal role in achieving successful UV DTF transfer outcomes. Proper preparation techniques, such as cleaning and pre-treating materials, are essential for ensuring optimal adhesion and print quality. For textiles, using a heat press to remove moisture can significantly enhance the bonding process. Similarly, for hard surfaces, thorough cleaning is crucial to prevent any residue from interfering with the transfer.

Moreover, understanding the specific requirements of different substrates is key. Each material may have its unique characteristics and treatment needs; thus, spending time to prepare them adequately can lead to better bonding and smoother transfer. This proactive approach will enhance the vibrancy and durability of your UV DTF designs, ultimately leading to higher customer satisfaction.

Optimizing Temperature and Pressure Settings in Transfers

The effectiveness of UV DTF transfers is highly dependent on the correct temperature and pressure settings during application. When dealing with various substrates, it is crucial to adjust these settings accordingly to achieve the best results. Generally speaking, a medium pressure and a temperature of approximately 300°F (149°C) is effective; however, certain materials might require specific adjustments.

To ensure the optimal performance of your UV DTF transfers, conducting preliminary tests on sample materials is highly recommended. These test applications not only help identify the ideal temperature and pressure for each substrate but also allow you to troubleshoot potential issues before full-scale production. In turn, this preparation can lead to greater consistency and higher-quality transfers.

Staying Ahead: Innovations in UV DTF Technology

As UV DTF technology continues to advance, businesses must stay informed about recent developments to maintain a competitive edge. The introduction of eco-friendly UV inks signifies a positive trend towards sustainability within the printing industry. These innovations not only contribute to environmental preservation but also offer improved performance and safety for printers.

Additionally, advancements in printer technology have significantly enhanced color fidelity and product output speeds. By regularly updating your equipment and techniques to incorporate these innovations, you can improve manufacturing capabilities and ensure that your UV DTF prints meet the ever-evolving demands of the market. Adapting to shifts in technology will ultimately benefit your business and keep you relevant in a competitive landscape.

Frequently Asked Questions

What is UV DTF transfer technology and how does it work?

UV DTF (Direct to Film) transfer technology involves printing designs onto a specialized film using UV inks. After printing, the film is applied to various surfaces, allowing for vibrant and durable prints that can withstand everyday use.

What are the best tips for achieving successful UV DTF transfer applications?

To achieve successful UV DTF transfers, choose high-quality transfer films, optimize your printer settings, and master the curing process. Additionally, properly prepare your substrates and control temperature and pressure during application to ensure the best results.

How can I ensure the durability of my UV DTF prints?

To ensure the durability of your UV DTF prints, follow proper curing techniques as per the manufacturer’s guidelines and use high-quality inks and films. Additionally, store your printed items in a cool, dry environment to maintain their quality.

What substrates can I use for UV DTF transfer applications?

UV DTF transfer technology can be applied to a wide range of substrates, including textiles, plastics, and metals. Each substrate may require specific preparation and heat press settings for optimal adhesion and print quality.

Why is substrate preparation important in the UV DTF process?

Substrate preparation is crucial in UV DTF transfer because it enhances adhesion and improves the quality of the final print. For best results, clean surfaces thoroughly and pre-treat textiles to remove moisture before transfer.

What recent developments can enhance my UV DTF printing process?

Recent developments in UV DTF technology include advances in printer designs that improve color fidelity and production speed, as well as the introduction of eco-friendly UV inks. Staying informed on these updates can enhance your printing capabilities and sustainability.

| Key Aspects | Description |

|---|---|

| Introduction to UV DTF Transfers | UV DTF transfer technology is innovating the printing industry by allowing vibrant designs to be printed on various surfaces using UV inks on special film. |

| Understanding UV DTF Transfer Technology | This method transfers digitally created designs to substrates, ensuring vivid colors and durability through a process of heat and pressure application. |

| Choose the Right Transfer Film | High-quality films designed for UV DTF increase adhesion and vibrancy, avoiding issues like poor color saturation. |

| Optimize Your Print Settings | Correct printer profiles for UV inks and high-resolution settings are essential for avoiding ink bleeding and ensuring clear imaging. |

| Master the Curing Process | Following curing guidelines is crucial for durability and color integrity; inadequate curing can lead to defects. |

| Prepare Your Substrates | Proper substrate preparation, including cleaning and pre-treating, significantly enhances final transfer quality. |

| Control Temperature and Pressure | Correct heat press settings based on materials are essential for successful transfers, generally around 300°F (149°C). |

| Conduct Test Prints | Testing prints on scrap materials allows for troubleshooting and optimization before full production runs. |

| Proper Storage for Long-Lasting Quality | Storing printed items in cool, dry environments helps maintain quality and prevents damage for durability. |

| Recent Developments in UV DTF Technology | Continuous evolution includes advancements in printer technology and sustainable practices with eco-friendly inks. |

Summary

UV DTF transfer technology represents a significant advancement in the printing field, offering a revolutionary method for high-quality prints on diverse materials. By understanding the processes and embracing best practices outlined above, printing professionals can ensure vibrant, durable, and appealing designs that meet client demands. As the innovations within UV DTF technology advance, staying informed will empower you to leverage these changes, keeping your business competitive and adaptable in a fast-evolving industry.