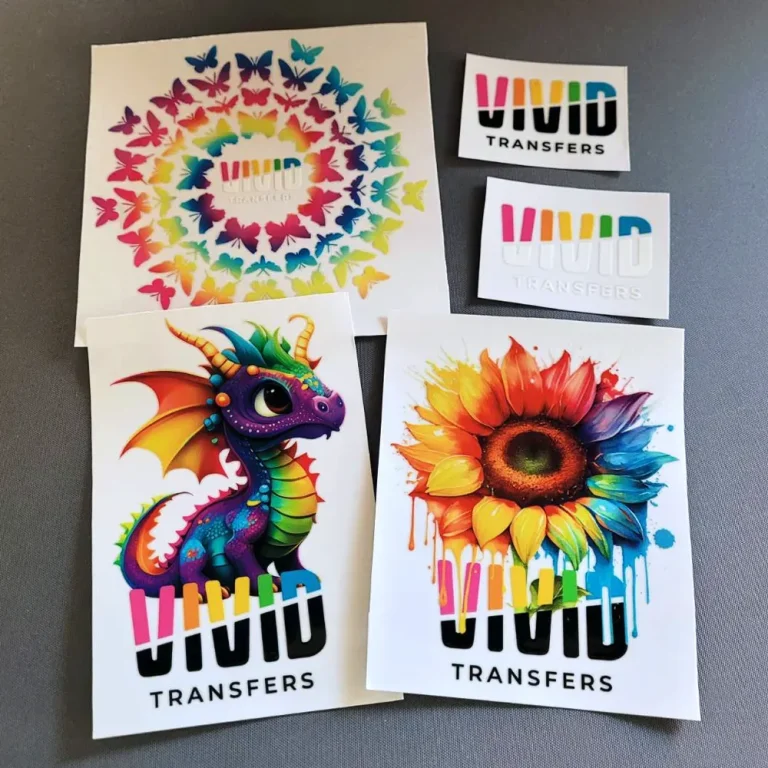

UV DTF transfers are revolutionizing the printing landscape, merging traditional and contemporary techniques to deliver stunning results. This innovative method utilizes UV DTF printing technology to create vibrant, durable designs suitable for a variety of applications, from apparel to hard surfaces. If you’re wondering how to use UV DTF transfers effectively, you’ll find that the process is both straightforward and rewarding. The benefits of UV DTF transfers include their versatility and long-lasting quality, making them an attractive choice for both beginners and experienced printers alike. As we explore the essentials of equipment for UV DTF printing and the step-by-step process, you’ll gain a comprehensive understanding of how this technique can transform your creative projects.

Direct-to-Film (DTF) technology is at the forefront of modern printing solutions, allowing for a seamless transfer of intricate graphics onto numerous substrates. By utilizing UV-curable inks, this process not only enhances the vibrancy of colors but also ensures that the final print remains intact under various conditions. If you’re considering the advantages of DTF techniques, you’ll find that they simplify the customization of apparel and promotional products alike. Understanding the equipment required for optimal results, such as specialized printers and heat presses, is essential for achieving professional-quality finishes. This guide aims to delve into the nuts and bolts of DTF technology, helping you harness its full potential for creative printing endeavors.

Understanding the Basics of UV DTF Printing

UV DTF printing, or Direct-to-Film printing, combines the advantages of UV printing technology with the flexibility of transfer films. This method utilizes specialized UV-curable inks that are vibrant and long-lasting, giving your printed designs a striking appearance. When applying these inks onto a transfer film, it is crucial to ensure that the printing process is completed correctly so that the colors not only pop but also adhere well to various surfaces.

Once the inks are printed on the transfer film, they undergo a curing process using UV light. This curing process solidifies the inks and prepares them for the transfer to the desired substrate. The fusion of these two technologies makes UV DTF printing a favorite choice among graphic designers and businesses looking for customizable printing solutions. By understanding this foundational process, beginners can begin their journey into the world of UV DTF.

Essential Equipment for UV DTF Transfers

To embark on your UV DTF printing journey, it’s important to equip yourself with the right tools and machinery. A high-quality UV printer is required, capable of using UV-curable inks specifically designed for DTF transfer. This printer is pivotal as it directly affects the clarity and quality of the output images on your transfer films.

Besides the UV printer, a quality heat press is another essential piece of equipment. This machine efficiently applies heat and pressure, ensuring that your printed designs are transferred accurately onto the intended materials such as cotton, metal, or wood. Additionally, utilizing the correct transfer films tailored for UV DTF processes will optimize adhesion and enhance the overall finish of your printed products. With the right equipment, the transition from design to product becomes seamless.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing stands for UV Direct-to-Film printing, a technology that combines UV printing and transfer film methods. A UV printer applies UV-curable inks to a special transfer film, which is then cured under UV light. This process allows for vibrant and durable designs on various surfaces when the film is transferred using heat.

What equipment do I need for UV DTF printing?

To start with UV DTF printing, you’ll need a few essential pieces of equipment: a UV printer capable of using UV DTF inks, a heat press for transferring designs onto materials, UV DTF inks specifically formulated for UV curing, and the appropriate transfer films that allow for high-quality adhesion.

What are the benefits of UV DTF transfers compared to other printing methods?

The benefits of UV DTF transfers include remarkable durability, as the prints are resistant to scratches and fading. Additionally, UV DTF technology is versatile, allowing for printing on a wide range of materials. It’s also user-friendly, enabling beginners to create high-quality custom prints without significant training.

How do I create custom designs for UV DTF transfers?

To create custom designs for UV DTF transfers, you should use graphic design software to craft your artwork. Ensure your designs are suitable for the UV DTF format, considering resolution and color profiles, to achieve optimal results during the printing process.

Can I use UV DTF transfers on different types of materials?

Yes, UV DTF transfers are highly versatile and can be used on numerous materials, including textiles like cotton and polyester, as well as hard surfaces like wood, metal, and plastics. This flexibility makes UV DTF printing suitable for a wide array of projects.

What makes UV DTF technology an ideal choice for beginners?

UV DTF technology is ideal for beginners due to its straightforward process, which involves minimal steps to achieve professional-grade results. With the right equipment and a clear understanding of the steps involved—from design creation to transfer application—users can efficiently create customized products.

| Key Concept | Description |

|---|---|

| What Are UV DTF Transfers? | A printing technology that combines UV printing with transfer film to create vibrant, durable designs on various surfaces. |

| Technology Overview | Integrates the features of UV printing with DTF methods for custom printing projects. |

| Equipment Needed | Includes a UV printer, heat press, UV DTF inks, and specially designed transfer films. |

| Step-by-Step Process | 1. Design Creation 2. Printing 3. Curing 4. Transfer |

| Applications | 1. Custom Apparel 2. Promotional Items 3. Unique Decor Pieces |

| Benefits | Durability, versatility, and ease of use make UV DTF transfers advantageous for beginners. |

Summary

UV DTF transfers are revolutionizing the world of custom printing by providing an innovative solution that combines high-quality results with enhanced durability. This cutting-edge technology not only allows for striking designs on various materials but also simplifies the printing process, making it accessible for beginners. By investing in the right equipment and understanding the UV DTF process, you can open the door to a world of creative possibilities. Whether you’re looking to create custom apparel, promotional items, or unique decorative pieces, UV DTF transfers offer a compelling option for personal and professional projects alike. As technology continues to advance, the future of UV DTF transfers appears brighter, promising even more exciting developments in the years to come.