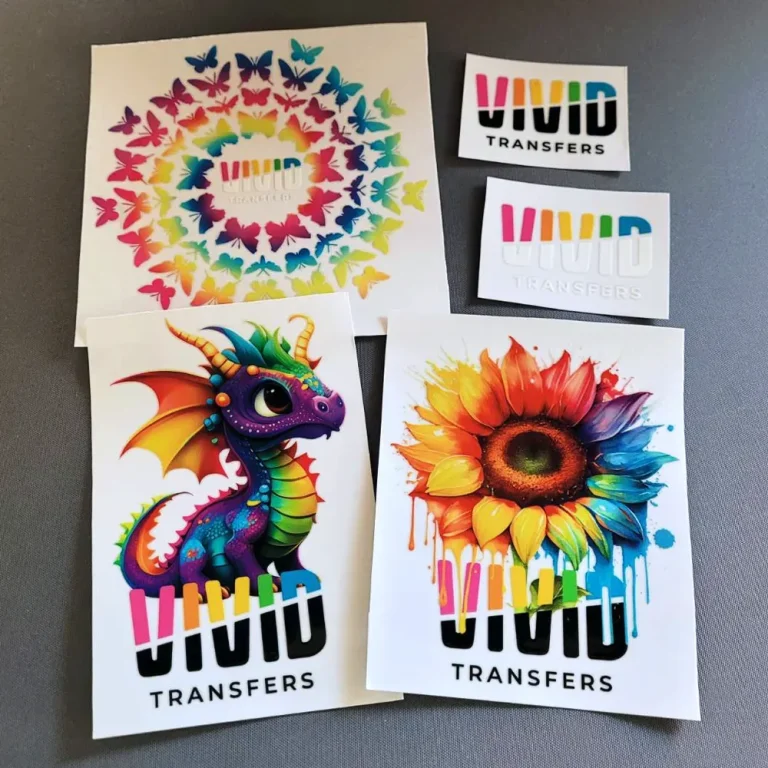

UV DTF transfers are at the forefront of modern printing technology, combining innovation with high-quality results. This cutting-edge method, known as Direct to Film printing, utilizes ultraviolet inks that cure instantly under UV light, allowing for incredible color vibrancy and excellent durability. As businesses strive to offer unique and personalized custom printing solutions, understanding UV DTF printing is essential for staying ahead in the competitive market. This technique not only adapts to various materials, including textiles and plastics, but also ensures that prints maintain their brilliance over time. Whether you’re in need of promotional items or customized merchandise, UV DTF provides a reliable solution that meets the demands of today’s consumers.

When discussing UV DTF transfers, it’s also valuable to consider alternative terms such as Direct to Film printing, a technique that has significantly changed the landscape of graphic reproduction. By leveraging advanced UV inks and curing methods, printers can achieve high-quality, long-lasting prints across a variety of surfaces. This innovative printing technology allows businesses to create custom designs with vivid colors that stand out in today’s marketplace. As demand for personalized products grows, understanding the versatility and application of Direct to Film printing is crucial for any business aiming to thrive in the custom printing sector.

Understanding UV DTF Transfers

UV DTF transfers, or Direct to Film printing, utilize cutting-edge technology to deliver outstanding print quality and durability. This innovative process employs UV-curable inks that integrate seamlessly with various substrates, making it ideal for producing vibrant graphics on diverse materials. Unlike traditional methods that may require multiple steps, UV DTF allows for immediate curing, thus enhancing the color vibrancy and ensuring exceptional adhesion. As a result, businesses can reap the benefits of high-quality prints that stand the test of time.

The versatility of UV DTF transfers is unparalleled, enabling customization across a wide range of products. From apparel and promotional items to signage and packaging solutions, this printing technology can effectively meet the needs of different industries. With tailored designs, businesses can engage with consumers more effectively, catering to their specific preferences and trends. Understanding the intricacies of UV DTF transfers sets the foundation for leveraging this technology to enhance branding and consumer engagement.

The Breakdown of UV DTF Printing Technology

The UV DTF printing process involves an intricate series of steps that contribute to its remarkable output. Initially, high-resolution designs are printed onto a specialized transfer film using advanced UV inks. The critical aspect of this technique is the immediate curing process where ultraviolet light solidifies the ink, ensuring that the prints are ready for application without delay. This approach not only boosts efficiency but also guarantees that the prints adhere firmly to a range of substrates.

Moreover, the technology has evolved significantly over the years. Current advancements in UV ink formulations allow for better durability and flexibility, increasing the printing options available to businesses. By understanding the technical aspects of UV DTF printing, companies can utilize this information to optimize their production processes, enhance their offerings, and remain competitive in the market.

Benefits of UV DTF Transfers for Businesses

The advantages of UV DTF transfers extend beyond mere print quality. One of the primary benefits is the durability of UV inks, which offer resistance to fading, scratching, and environmental elements. This resilience ensures that printed items look fresh and vibrant for extended periods, making them an excellent investment for promotional products and merchandise. Businesses can build confidence in their offerings knowing that customers will receive high-quality and long-lasting items.

Additionally, the versatility of UV DTF printing allows companies to expand their product lines quickly and economically. With the ability to print on a multitude of surfaces, businesses can diversify their offerings from custom apparel to unique packaging solutions. This adaptability also caters to growing consumer demand for personalized products, enabling businesses to tap into new markets and boost customer satisfaction.

Emerging Market Trends in UV DTF Printing

The market for UV DTF printing is on an upward trajectory, driven by evolving consumer preferences and advancements in technology. One notable trend is the increasing demand for customization, as more consumers seek personalized goods. This shift has encouraged businesses to invest in UV DTF technology, allowing them to create bespoke designs that resonate with individual customers. The ability to offer personalized experiences not only enhances customer satisfaction but also encourages repeat business.

Moreover, sustainability is increasingly influencing the market landscape. Consumers are becoming more environmentally conscious, prompting brands to seek eco-friendly printing solutions. UV inks, known for their low volatility organic compounds (VOCs), align well with these sustainability goals, offering a greener alternative to traditional printing methods. By adopting UV DTF printing technology, businesses can respond to this trend while bolstering their commitment to environmentally responsible practices.

Diverse Applications of UV DTF Printing

The applications of UV DTF printing are vast and encompass various sectors. In the apparel industry, custom prints on t-shirts, hoodies, and other garments have become increasingly popular, enabling brands to create unique clothing that stands out. Beyond textiles, UV DTF technology is equally effective in producing durable signage, showcasing its ability to withstand challenging conditions while delivering attention-grabbing visuals.

Moreover, this versatile printing method extends to packaging solutions, where vivid colors and detailed images enhance product appeal on the shelves. From unique promotional items such as mugs and pens to eye-catching packaging, UV DTF printing allows businesses to create customized merchandise that effectively communicates their brand message. This flexibility in applications makes UV DTF a valuable asset for companies looking to embrace innovative printing technologies.

Best Practices to Maximize UV DTF Printing Efficiency

To achieve optimal results with UV DTF transfers, implementing best practices during the printing process is essential. One key practice is selecting quality materials, including premium transfer films and compatible UV inks. Utilizing materials that complement your substrate can significantly enhance print quality and durability, ensuring that the result meets or exceeds customer expectations.

Additionally, regular maintenance of printing equipment is crucial to maintaining consistent output quality. Keeping printers clean and operating smoothly prevents production delays and guarantees that colors remain true throughout the printing session. Testing prints before commencing full production runs is also advisable, allowing businesses to fine-tune their processes and achieve the desired color accuracy and print quality.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers involve a unique printing process where designs are printed on a specially coated film using high-quality UV inks. The UV curing technology instantly solidifies the inks with ultraviolet light, allowing for vibrant and durable prints on various substrates. This process enhances adhesion and color vibrancy, making UV DTF printing a preferred choice for many custom printing solutions.

What are the benefits of using UV DTF printing?

UV DTF printing offers numerous benefits, including high durability due to UV inks being resistant to fading and scratching. This printing technology allows for rich color reproduction, particularly with white ink, enabling vibrant designs on both dark and light surfaces. Furthermore, UV DTF transfers are versatile, providing the capability to print on a wide range of materials, which makes them ideal for custom merchandise.

Can UV DTF transfers be used on different materials?

Yes, UV DTF transfers can be applied to a variety of materials, including textiles, plastics, metals, and wood. This versatility in application makes UV DTF printing suitable for various products such as apparel, signage, packaging solutions, and promotional items. This adaptability is one of the key reasons businesses choose UV DTF printing for their custom printing needs.

How does UV DTF printing compare to traditional printing methods?

UV DTF printing surpasses traditional printing methods in quality and efficiency. Unlike standard DTF methods, UV DTF utilizes advanced UV-curable inks that cure instantly under ultraviolet light, which enhances color vibrancy and adhesion. This modern printing technology not only produces more durable and vivid prints but also significantly speeds up production times.

What industries benefit from UV DTF printing technology?

Various industries can benefit from UV DTF printing technology, including apparel manufacturing, signage, packaging, and promotional products. The growing consumer demand for customization and personalized merchandise has propelled the popularity of UV DTF transfers across these sectors, allowing businesses to meet unique consumer demands effectively.

What should I consider for successful UV DTF printing?

For successful UV DTF printing, it is essential to select quality materials, including transfer films and UV inks that are compatible with the intended substrate. Regular maintenance of printing equipment, conducting test prints for color accuracy, and adhering to manufacturer guidelines are critical best practices for achieving optimal results in custom printing solutions.

| Key Point | Description |

|---|---|

| What is UV DTF? | UV DTF printing uses UV-curable inks for vibrant, durable prints on various surfaces. |

| Technology and Process | Involves printing on transfer film, UV curing, and applying to substrates. |

| Advantages | Includes high durability, versatility, and rich color reproduction due to white ink. |

| Market Trends | Growing demand for customization and advancements in technology drive market growth. |

| Applications | Used in apparel, signage, packaging, and promotional items. |

| Best Practices | Include choosing quality materials, maintaining equipment, and conducting test prints. |

Summary

UV DTF transfers are revolutionizing the realm of custom printing by offering superior quality, enhanced durability, and unprecedented versatility. This innovative printing method employs UV-curable inks, enabling businesses to create vibrant prints that adhere seamlessly to a wide range of materials, from textiles to plastics. As industries continue to seek more efficient and effective printing solutions, the importance of understanding and leveraging UV DTF transfers is ever-increasing. By adopting best practices and staying updated on market trends, businesses can maximize the potential of this cutting-edge technology, ultimately leading to higher customer satisfaction and operational success.